PO Box 1216 •

7595 US Hwy 50 N

Lamar CO 81052-1216

719-336-9006 • 719-336-2402 Fax

Thank you to a long-time repeat customer:

Crowell Water Well Service, Inc.

Claude, Texas

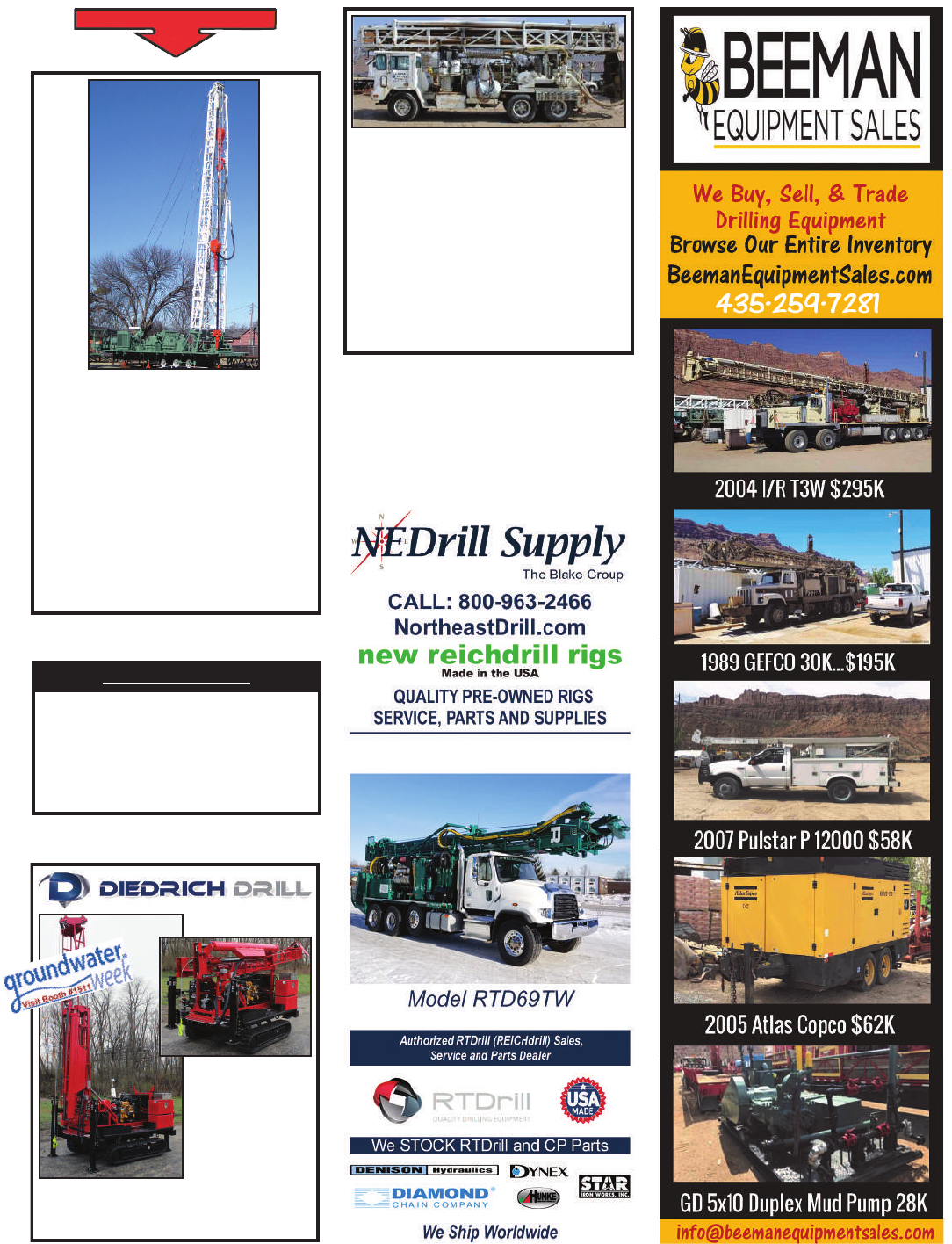

SEMCO S6,000 Pump Hoist, 44’ derrick extension, hot shift PTO

automatic transmission, remote control, (2) pipe racks with

ratchet straps, sandreel 1500’ capacity, hydraulic oil cooler 12V DC,

(2) 96” toolboxes, 11’ steel flatbed, mounted on 2019 Ford F-550,

regular cab, 6.7L diesel, automatic, 4x4.

CALL OUR TOLL-FREE

NUMBER: 800-541-1562

SEMCO INC.

SEMCO INC.

E-mail: semcopumphoist@gmail.com

www.SEMCOoflamar.com

2

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Breaking News..................................................................13

Classified Section:

WorldWide SUPER MART™

WorldWide SUPER MART™..................57-72

Dealmakers.....................................................................8,39

Education Connection......................................................32

Fun Page............................................................................32

Hot Off the Press.................................................................9

Industry Announcements.................................................48

Obituary: Anderson, Jr., Joseph Prentiss “Andy”.........15

Obituary: Jenkins, Charles Curtis...................................15

Obituary: Pickens, Jr., Thomas Boone “T. Boone”........26

Obituary: Roth, Charles Thomas “Chuck”.....................15

Obituary: Wragg, Gregory G. “Greg”..............................15

Photo Gallery.................................................................31,47

Product Spotlight..............................................................22

Where are you planning to go?........................................36

Who’s in the News.............................................................13

WorldWide Association Memberships

WorldWide Association Memberships................................35

WorldWide Business Directory™

WorldWide Business Directory™.............................10,11,12

WorldWide

WorldWide

.........6

Editorial Focus for November - Gas and Oil

C&G

DIR

ENV

EXB

G&O

GEO

MIN

WTR

Acker Drill Company...........................................................30

Allegheny Instruments........................................................28

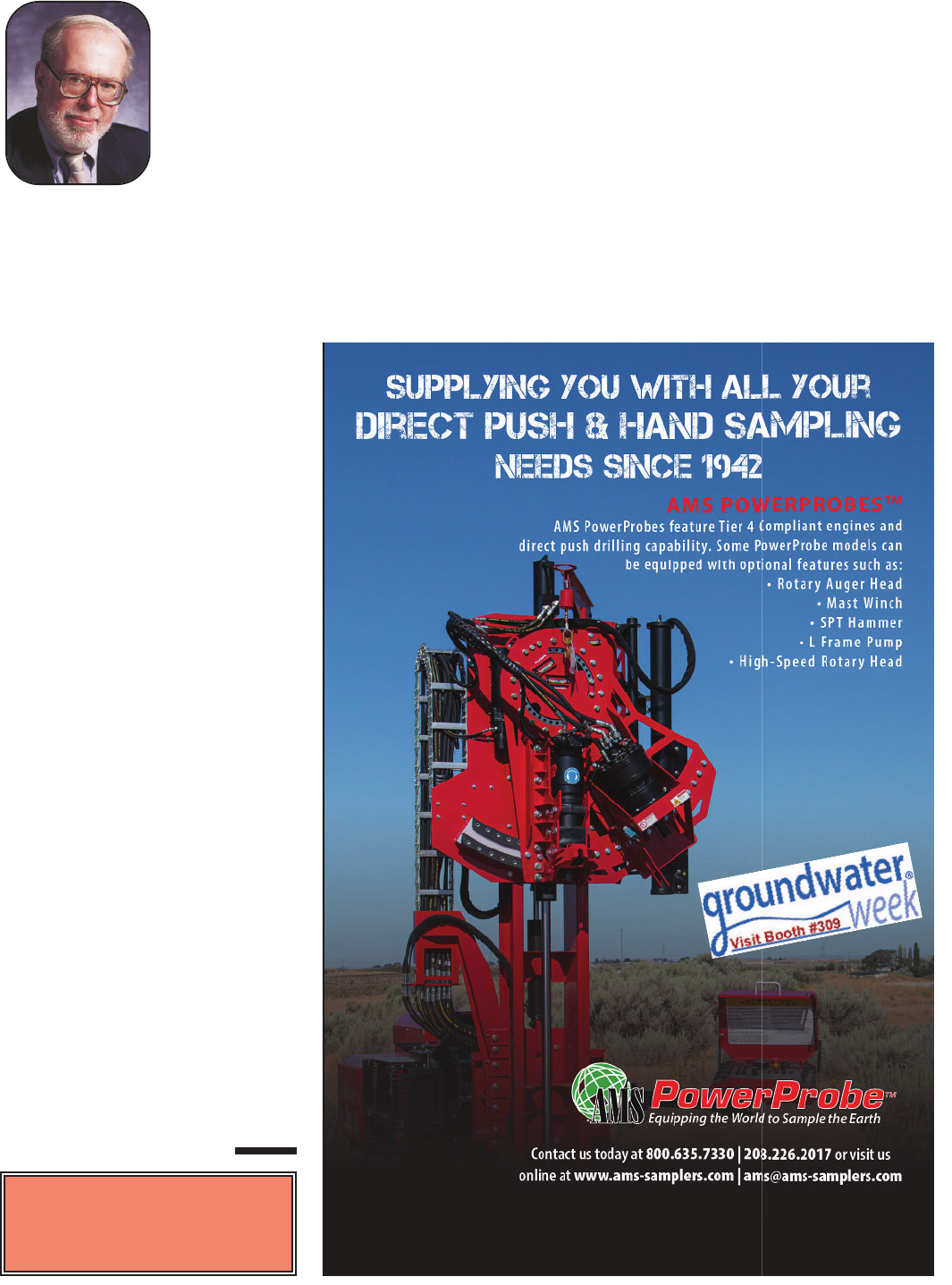

AMS, Inc...............................................................................7

Armstrong Machine Co., Inc. (AMCI)..................................26

Atlantic Screen & Manufacturing, Inc. (ASI)........................18

Baker Water Systems.........................................................33

B

aroid Industrial Drilling Products (IDP)…....…….…..........46

BESTOLIFE

®

Corporation...................................................25

Better Water Industries, Inc.................................................34

Bit Brokers International.....................................................41

Bitco, Inc.............................................................................36

Blackadar Insurance Agency...............................................17

Bloom Mfg., Inc...................................................................44

CONEXPO-CON/AGG

®

......................................................70

Drill King International.........................................................51

Drilling Equipment Sales, Inc. (DES)..................................72

Drilling Supply & Mfg (DSM)...............................................54

DRILLMAX

®

........................................................................71

Empire State Water Well Drillers Assoc. (ESWWDA) Ann. Mtg..50

Flomatic

®

Corporation.........................................................37

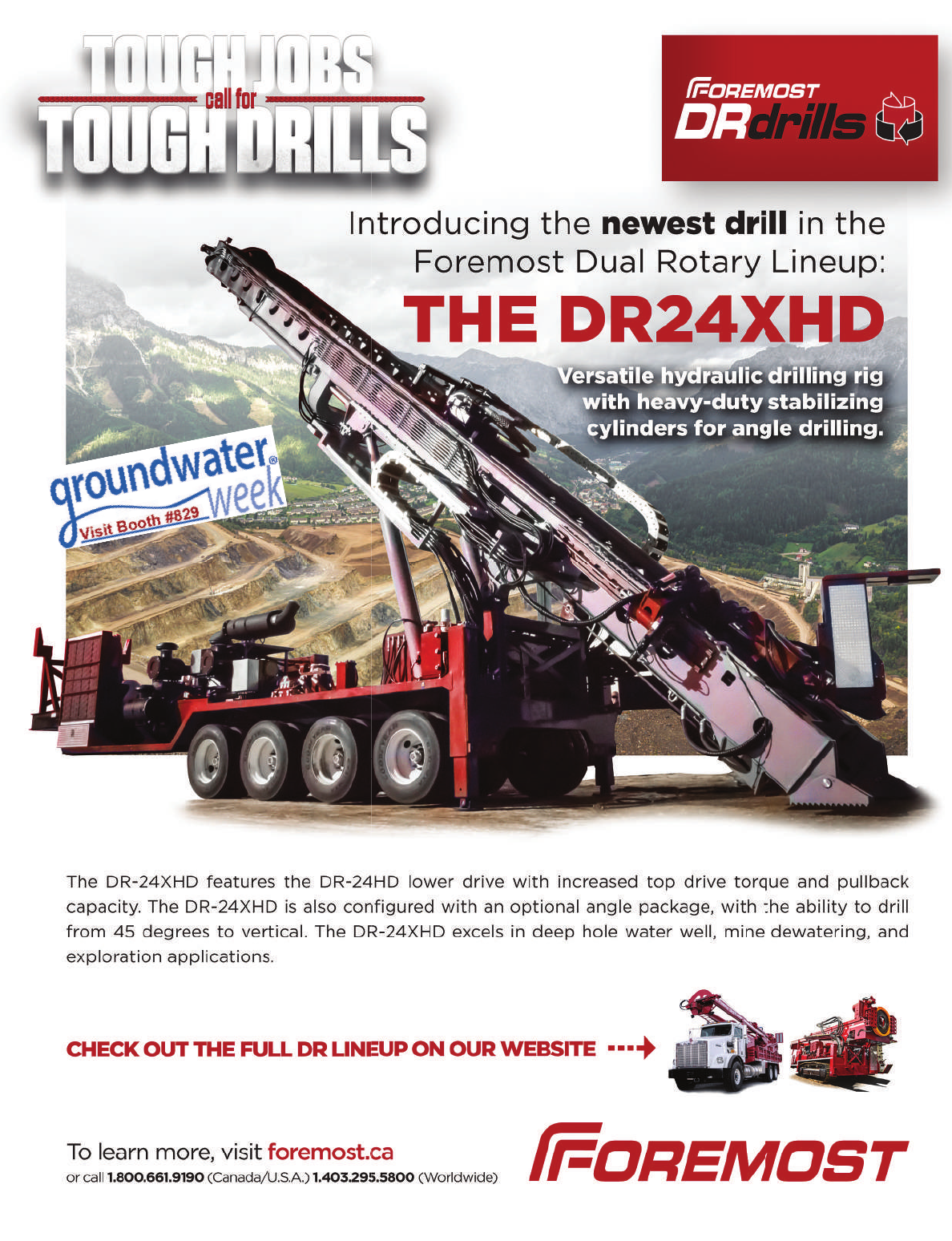

Foremost Industries............................................................69

GEFCO, Inc. (an Astec Industries Company).......................1

GeoPro, Inc.........................................................................55

Geoprobe Systems

®

............................................................19

Geothermal Supply Company, Inc. (GSC)..........................52

Hole Products.....................................................................21

Infinity Tool Manufacturing....................................................4

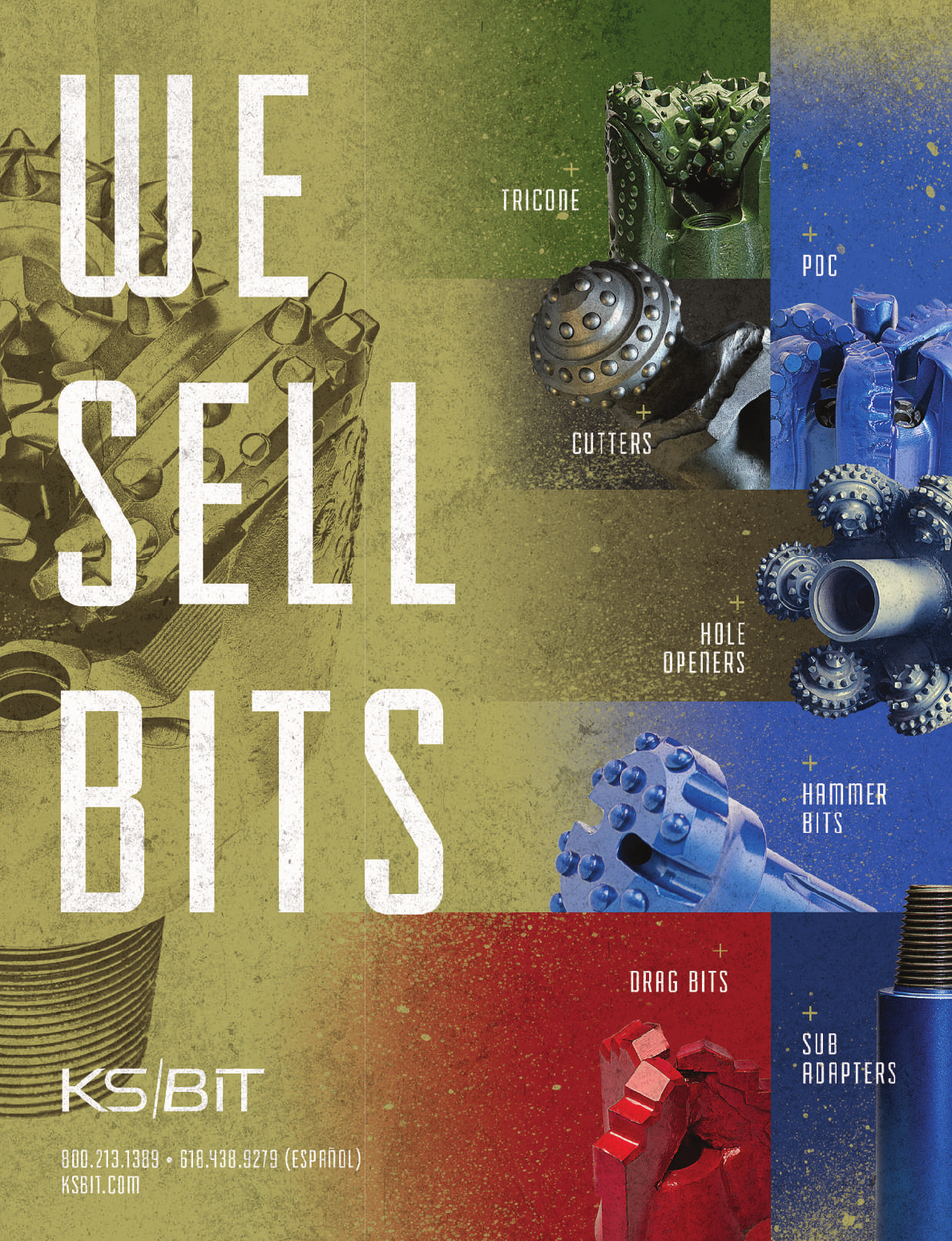

KS Bit, Inc.............................................................................3

Louisiana Ground Water Association (LGWA) Convention...20

Mills Machine Company, Inc...............................................16

Mobile Drill Intl....................................................................27

Mountain States Ground Water Expo.................................24

N&N Drilling Supply.............................................................56

Numa Hammers.................................................................43

Oklahoma Ground Water Assoc. (OGWA) Conference.......42

Palmer Bit Company...........................................................14

Proheat...............................................................................23

Rockmore International.........................................................9

SEMCO, Inc..........................................................................2

Star Iron Works, Inc............................................................48

Star Iron Works, Inc............................................................49

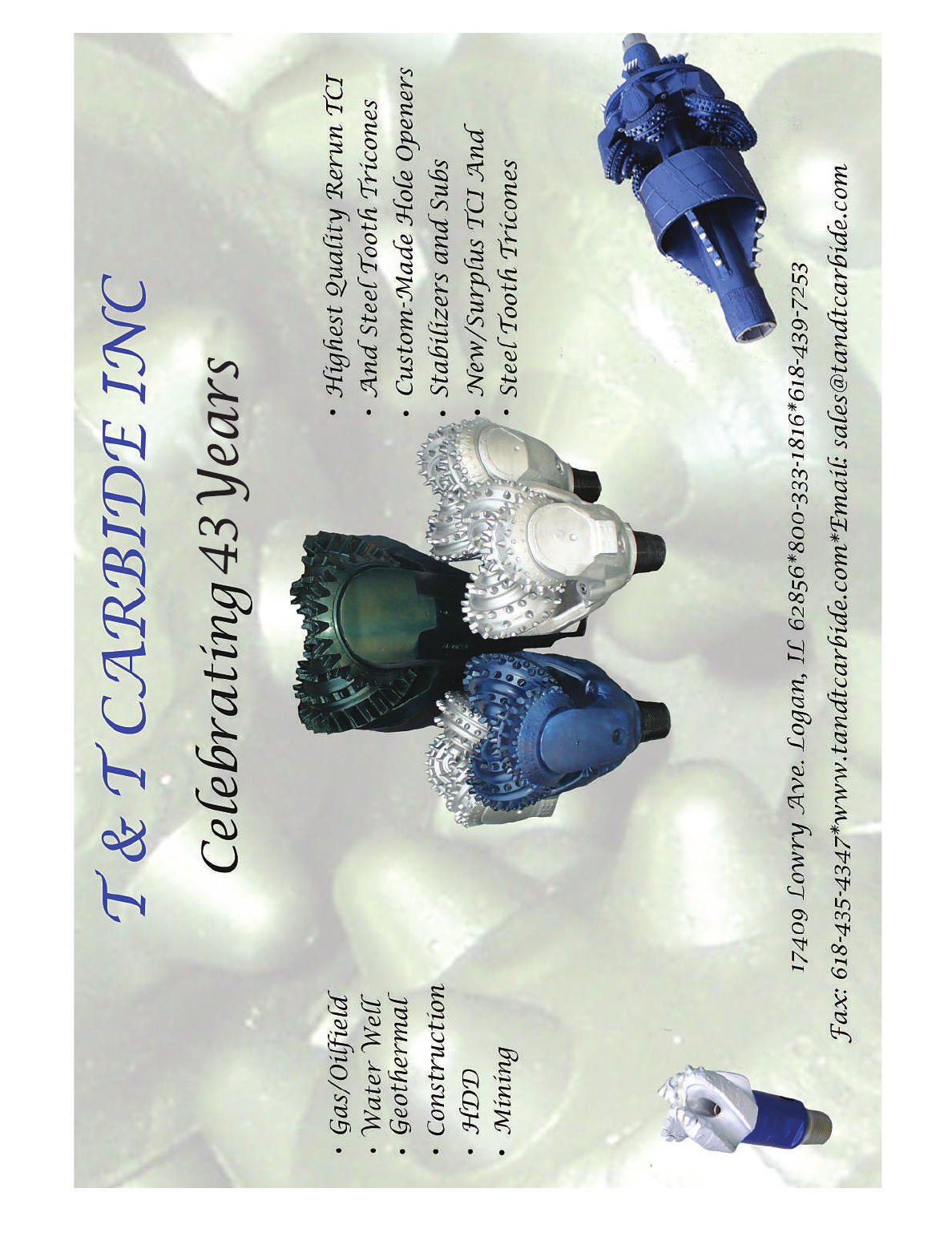

T&T Carbide, Inc.................................................................38

TDH Manufacturing Inc.......................................................29

Throop Rock Bit Company..................................................45

Underground Construction Technology (UCT) Conf……....13

Utah Ground Water Association (UGWA) Conf. and Expo..53

Well-Vu, Inc.........................................................................40

Wyo-Ben, Inc......................................................................15

Advertisers

Featured Editorial

C&G - Construction/Geotechnical

E

NV - Environmental

G&O - Shallow Gas and Oil

MIN - Mining

DIR - Horizontal Directional Drilling

E

XB - Exploration/Blasthole

GEO - Geothermal

W

TR - Water

Storkson, Britt: “Thinking Outside the Box”...............8

Determining the Correct Drill for Your Project............28

E-News Flash

E-News Flash

Readers’ Choice

Readers’ Choice: Constructing the.....33

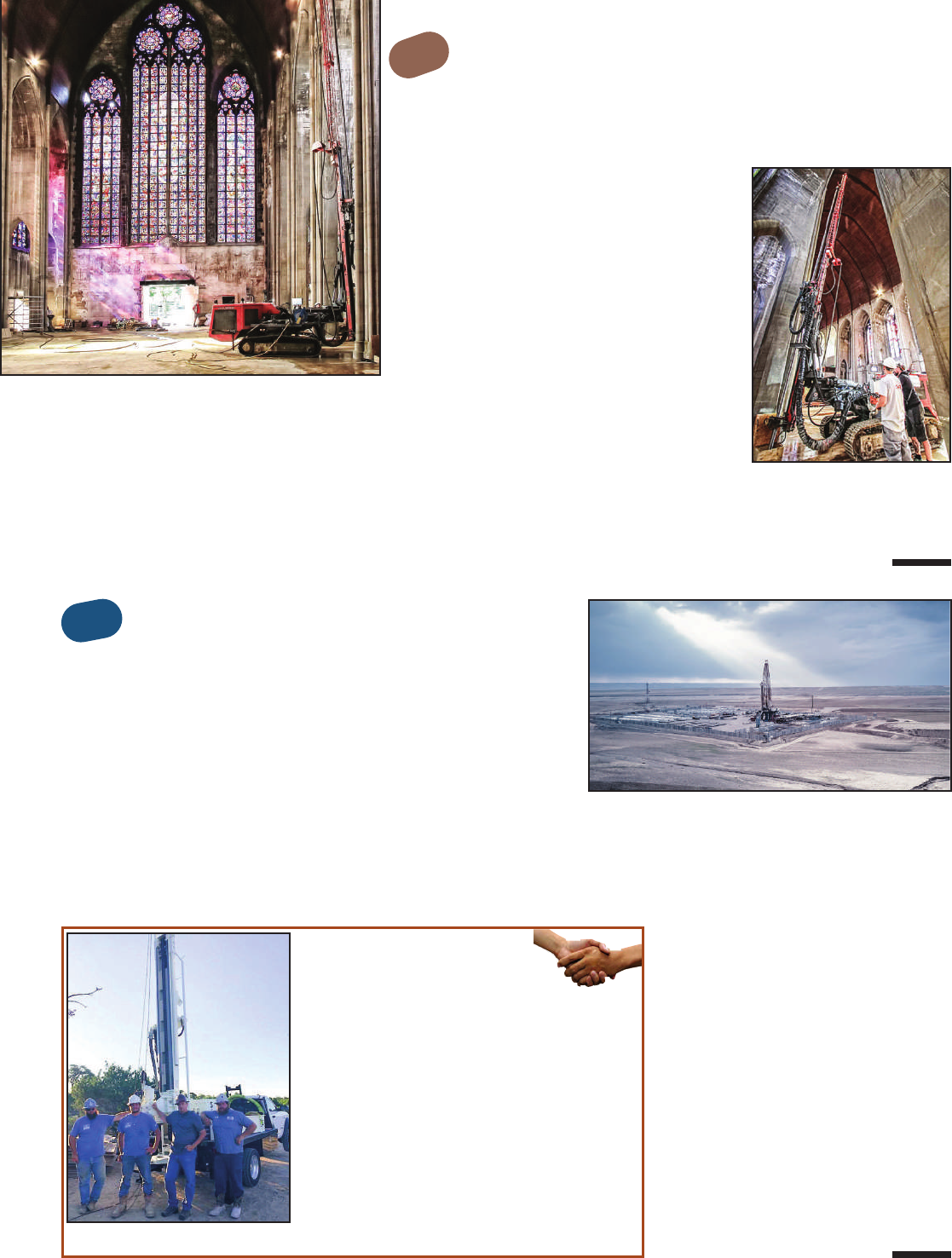

Drilling in a Church....................................................39

Battersby, Mark E.: Drilling Into Money Not Boring..7

Using Geomagnetic Data to Improve MWD..............29

D-Geo Pipeline Software for Horizontal Directional..44

New San Andres Drilling Program.............................49

Kwader, Thomas: Environmental Monitoring...........17

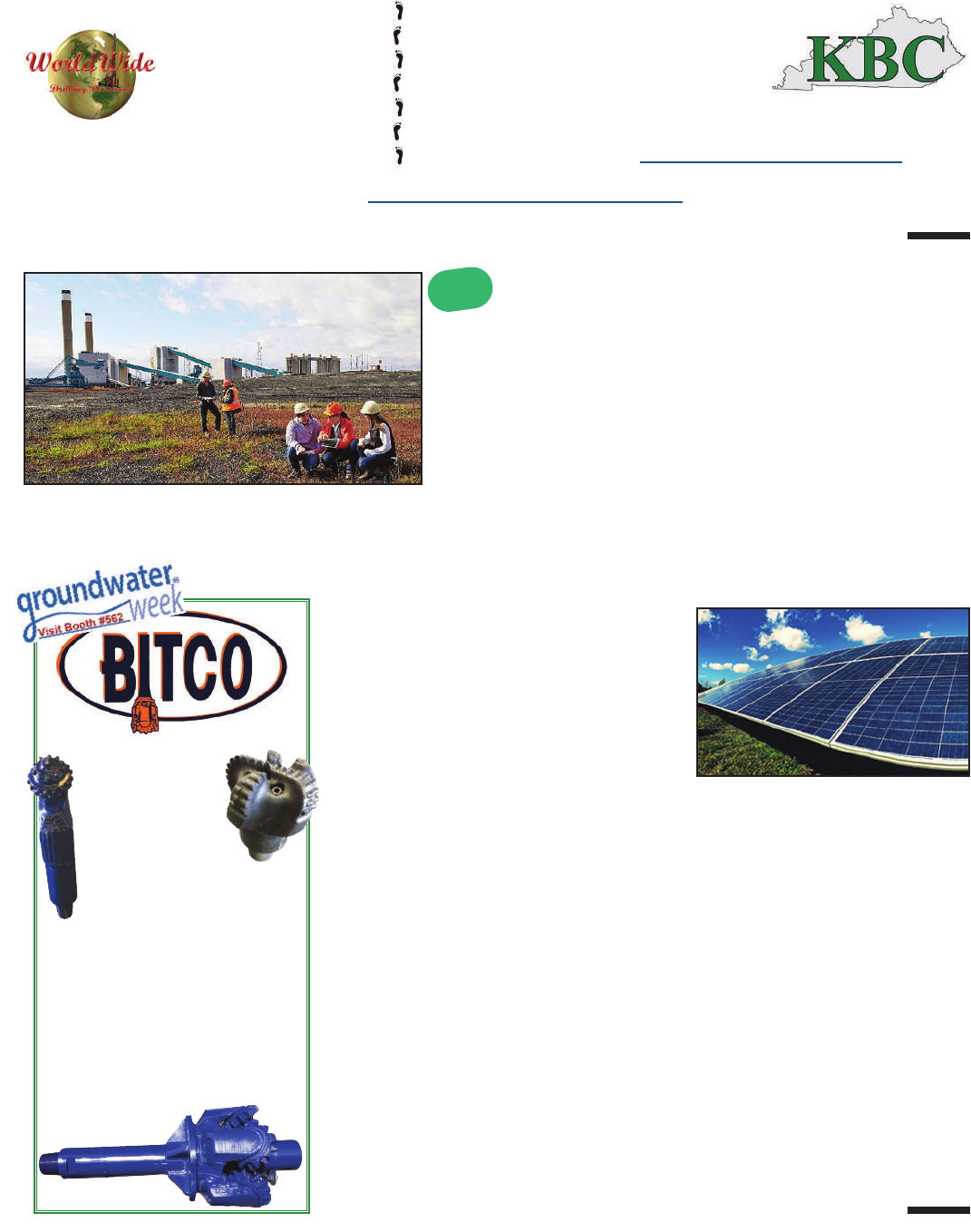

From Coal to Solar: Nanticoke Solar.........................36

What’s the Big Deal about Carbon Capture..............45

Wire, Jeremy: Tales from the Field..........................50

What Happens to Old Gas and Oil Wells?.................55

Five Ways to Battle Insider Threats...........................21

Program in Canada Use Simulators for Blasthole.....34

Connor, Tim: Obstacles, Learning, & Creativity.......42

White, Harold: Oil/Water Exploration.......................53

Dispelling the Myths Surrounding Hydraulic Fracturing..22

Frequently-Used Geological Terms Part 85..............25

Oil Production Expands in the Sarqala Field.............39

Unique Pipe Provides Solution for Produced Water..56

America’s Underappreciated Energy Source............20

“Smith, Billy Bob”: The “Idiot’s” Corner..................24

Installation Provides Opportunity for Study...............40

Core Drilling Leads to A New Age of Energy Generation..47

Wilson, Jr., Robert Evans: The Un-Comfort Zone II...12,52

Demand for Queensland’s Coal Soars......................16

Mining Report from Germany...................................37

Rasmussen, Tim: Water For Life International........18

Could the Mojave Desert Help Solve California’s......31

Ballard, Thomas: Notes from the Groundwater Guy.....32

Kuebelbeck, Jim: Through the Back Door!..............41

5

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

6

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

WorldWide

WorldWide

!

!

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The

c

ompl

e

t

e

magaz

ine

fo

r

th

e

dr

illin

g

in

dus

t

r

y

worl

dwide, owned by

drilling industry associates dedicated to bringing the most up-to-date

t

e

c

h

n

o

l

o

g

y

a

n

d

i

n

f

o

r

m

a

t

i

o

n

t

o

s

u

b

s

c

r

i

b

e

r

s

.

Co

v

e

r

i

n

g

const

r

uct

ion-

g

e

o

t

e

c

h

n

ic

a

l

,

d

ir

e

c

t

io

n

a

l

,

e

n

v

ir

o

n

me

n

t

a

l

,

e

x

p

lo

r

a

t

io

n

-

b

la

sthole

,

shallow

ga

s

& oi

l

,

ge

ot

he

r

m

a

l

,

m

i

ni

ng

,

wa

t

e

r

we

ll

,

ir

r

ig

a

t

io

n

,

wa

s

t

e

wa

te

r

; fro

m b

its

, to

p

u

mp

s

, to

r

ig

s

, to

ta

n

k

s

, th

r

o

u

g

h

wir

e

,

a

n

d

m

o

r

e

-

wha

t

e

v

e

r

i

t

t

akes t

o get

t

he

dr

i

l

l

i

ng

j

ob

c

om

pl

e

t

e

d

!

M

a

na

gi

n

g

Publish

er/

C

EO/

Pre

side

nt:

Veronica I. “R

o

nn

i

e

” Jo

nes

Vice President:

Troy Cunningham

C

h

i

e

f

M

a

rke

t

i

n

g

Of

f

i

ce

r:

Ed

M

o

ra

n

ski

Of

f

i

ce

Ad

m

i

n

i

st

ra

t

o

r:

M

i

ch

e

l

e

St

e

ve

n

s

Ed

i

t

o

r:

Bo

n

n

i

e

L

o

ve

Ed

i

t

o

ri

a

l

C

o

n

t

ri

b

u

t

o

r:

C

a

ro

l

Sch

i

m

p

f

Public Relat

ions Prof

essionals:

Kat

hy Heinrich

Jan Allen

Production/Webmaster: Marcel Schimpf

Representative:

Marie Cunningham

Editorial Contributors for this month:

Tom Ballard Mark Battersby Tim Connor Jim Kuebelbeck

Thomas Kwader Tim Rasmussen “Billy Bob Smith” Britt Storkson

Harold White Robert Evans Wilson, Jr. Jeremy Wire

Hyd/Eng Consultant:

Thomas Kwader, Ph.D.,P.G.

Consultant:

Mary Ann Pelletier

*

Editorial contributions & advertisements include statements of fact and opinions

that are the sole responsibility of the author and/or companies and do not

necessarily imply any opinion of the owners, management, or staff of

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

.

Images may have been altered for clarity.

Complete advertising information may be found at:

www.worldwidedrillingresource.com

or by calling 850-547-0102.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

makes every

effort

not

to place advertisements for “like” products on the same page in our

publication; this may occur however, due to size and space within the publication.

We regret any inconvenience this may cause our advertisers.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

i

s published monthly by:

WorldWide Drilling Resource, Inc.

, a Florida Corporation

PO Box 660 (

3089 Nor

thr

ide Lane)

Bonifay FL 32425-

0660.

Telephone: 850-

547-

0102 Fax: 850-

547-

0329

E-

mail: wwdr

@wor

ldwidedr

illingr

esour

ce.com

Website: www.wor

ldwidedrillingresour

ce.com

Copyr

ight

2019,

WorldWide Dr

illing Resource, Inc.

Seen by countless

WorldWide

. Publication Agreement No. 40892520. Back issues may be

requested. Cost per issue $10.00 USD. No part of this publication may be

r

epr

oduced in any manner

without the str

ict wr

itten consent of the publisher

s.

Adver

tising

r

ates

fur

nished

upon

r

equest.

Editor

ial

contr

ibutions

ar

e

welcome

subject to editor

ial r

eview.*

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

reser

ves the

right to refuse any advertisement

.

We

We

Re

c

y

c

le

Re

c

y

c

le

Happy Thanksgiving to all . . .

Wow! Here it is, one of the happiest times of the year. I remember as a very small child, this was the

day we got to go have a HUGE early dinner at the “BIG” house. You see we lived in

an 8’ x 32’+/- mobile home. And boy was it mobile - didn’t take a huge anything to

pull it - but it was all we needed as it was full of love. So we got cleaned up - which

meant the big round metal tub outside for our baths. (No, I don’t make these things

up!)

Up we went to grandmom’s house (she actually was our step-grandmother) - we

got to dust the BIG furniture, and play up and down the stairway that used to be where the servants lived that led to the

kitchen. Oh how I remember that elegant table with everything in its proper place - we even got to set that table. We didn’t

get to have the wine - but we got the tomato juice. That was such a great, mem-

orable time for us. This place used to house and train race horses in times gone

by. I used to dream about owning that place. Oh well - not in my lifetime.

Now that you can see what my fond memories of Thanksgiving are - I’m

sure you can now look back and think about yours ~ enjoy the step back in

time.

See the Teamwork Football Players here? Some companies say they have

a “Team”, but in reality, they have a group of people working for them. A true

team consists of “Individuals commited to a group effort - that is what makes a

team work, a company work, a society work, and a civilization work.” Now you

are speaking of a real team - The

WWDR

WWDR Team!

From all of us here - to all of you there -

Happy Thanksgiving. Any way we can help you, please call.

We Will See you on the trail! NEXT STOPS - PA Blasting,

Kentucky Blasting, and VEGAS!

With pen

(computer) in hand

. . .

Ronnie, Managing

Publisher

r

onnie@worldwidedrillingresource.com

850-547-0102

Featured Articles for November

What Happens to

Old Gas and Oil Wells?

Page 55

New San Andres

Drilling Program

Page 49

Oil Production

Expands in Kurdistan

Page 39

Unique Pipe Provides

Solution for Produced Water

Page 56

Dispelling

the Myths of

Hydraulic

Fracturing

Page 22

Drilling Into Money Not Boring

b

y Mark E. Battersby

Records: They Could Save Your Business a Bundle

As many drilling professionals begin the onerous tax preparation process, they’re once again dis-

covering just how important good records are for tax savings. Good records can help every drilling busi-

ness generate an accurate tax bill and ward off zealous Internal Revenue Service (IRS) auditors.

Surprisingly, the IRS does not require a business keep records in any one manner. Federal income

tax laws require only that every business keep “complete and accurate records.” Just what records a

drilling business needs to keep, what records it should retain and for how long, is unclear, so long as they produce an accurate

accounting of income and expenses.

T

o help prepare future or amended returns, it makes sense to keep a copy of the business’s tax returns permanently. The

IRS suggests tax-related records be retained until the “period of limitations” expires for each year’s return.

Typically, the IRS can come after a business for failing to report income for up to six years after filing if the amount is

greater than 25% of the operation’s gross income. If a deduction was claimed for a bad debt or worthless security, the IRS

recommends retaining supporting tax records for seven years.

When it comes to employees, the

IRS recommends keeping payroll

records on hand for at least four years

in case of an audit. This should include

all wages, pension payments, tip infor-

mation, W-2 and W-4 forms, and any

other related information.

If the drilling operation works with

independent contractors or third parties,

it may also be necessary to meet some

state record keeping requirements.

Virginia, for example, requires contracts

with independent contractors be kept

for at least five years.

With business property, the IRS sug-

gests retaining records until the period

of limitations ends for the tax year when

the property was disposed of. These

records will aid in calculating deprecia-

tion, amortization, or depletion deduc-

tions - and for determining any eventual

gain or loss.

Above all, avoid checks made out to

cash. In fact, whenever possible, avoid

using cash. More claimed tax deductions

are disallowed for lack of substantiation

rather than for being nondeductible.

Consulting with an attorney or tax

professional can help guide every

drilling business to a legal and tax-com-

pliant record keeping policy. To avoid

identity theft and to protect sensitive

business information, all business

records should be disposed of properly

or shredded.

Mark

michele@

worldwidedrillingresource.com

7

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

Howard Hughes Sr. applied for a

U.S. patent for this invention in

1908. Maybe you’ve heard of it.

Find out on page 17!

“Thinking Outside the Box”

b

y Britt Storkson

Owner, P2FlowLLC

The above saying implies, among other things, that

sometimes unconventional approaches are the best solution

to a given problem, instead of “the way we’ve always done it”.

About the word “convention”: I’m not talking about “a

convention, in the sense of a meeting, is a gathering of indi-

viduals who meet at an arranged place and time in order to discuss or engage in

some common interest.”

I mean: “A way in which something is usually done, especially within a partic-

ular area or activity.”

Convention is a common understanding of some thing or process. The word

“common” is important here because it should be, as close as possible, universally

understood. Like traffic light colors. Green is go, yellow comes before a red light,

and red is stop. One does not even need to be literate to understand this conven-

tion. It makes for near-instant comprehension, which is a good thing.

Language is largely the product of convention. It doesn’t matter how you say

something, as long as you are readily understood. The emphasis here should be

“immediate understanding”, not so much what the language is or isn’t. The univer-

sal language of air traffic control is English, not because it is a superior language,

but because it is the most commonly understood worldwide.

Sometimes accepted conventions can be a problem. The reason we have the

QWERTY typewriter keyboard is when typewriters first were invented, the makers

needed to slow the typists down because their crude (by today’s standards)

machines would jam. There have been several more efficient keyboard patterns

introduced over the years, but none have supplanted the QWERTY convention so far. Learning the new keyboard would

require considerable time and, with increased typing speed being the only advantage, most people conclude changing key-

boards isn’t worth the trouble.

When designing the computer controls human machine interface (HMI) part, it is always wise to use familiar and conven-

tional words, symbols, colors, and shapes wherever possible. Computers should conform to the operator, the operator should

not have to conform to the computer. The HMI part should be intuitive* enough so the average person can figure out much

of it even without any prior training. This doesn’t mean some training is not required, but the good controls designer makes

the system readily understood with a minimum of outside help.

*Intuitive: Using or based on what one feels to be true even without conscious reasoning; instinctive.

There is great profit in being “the first to market” and a “trendsetter” with a computer control system. It’s because if you

want to use their machine, you have to conform to their conventions, which may or may not be intuitive*. Often, they are pur-

posely not intuitive* because if they were simple and easy to use, we wouldn’t need the vendor. And the vendors often change

or “update” their software which, of course, requires more training and results in more billable hours for the vendor. “Updates”

can also introduce problems that were not there with the original software. So all of this amounts to computer operators

essentially becoming “slaves” to the computer and the computer vendor, instead of the computer being a “slave” to the oper-

ator.

While there’s nothing wrong with the pursuit of profit, there is a dark side to this scenario. What if the car you are driving

had the brake pedal relocated from the floor to a lever between the seats? Instead of pushing the pedal on the floor you had

to pull a lever between the front seats to apply the brakes. Most people would accept this change without much trouble until

an emergency situation came up: If a child ran out in front of the car, most people would instinctively “stomp on the brakes”.

They would not think about the lever relocation for at least several seconds and, by that time, it would be too late to avoid

serious injury or worse.

So while conventional changes may be necessary and even a good thing, they must not be taken lightly. I find it best to

ask the users what they would most comfortable with, not imposing my biases on

the user. If the users want the “stop” button to say “halt” instead of “stop,” I don’t

have any problem with it. The operators are using this thing, and they should have

the primary consideration when it comes to the computer controls system they are

expected to operate.

Britt

Britt Storkson may be contacted via e-mail to

michele@worldwidedrillingresource.com

8

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

D

e

a

l

m

a

k

e

r

s

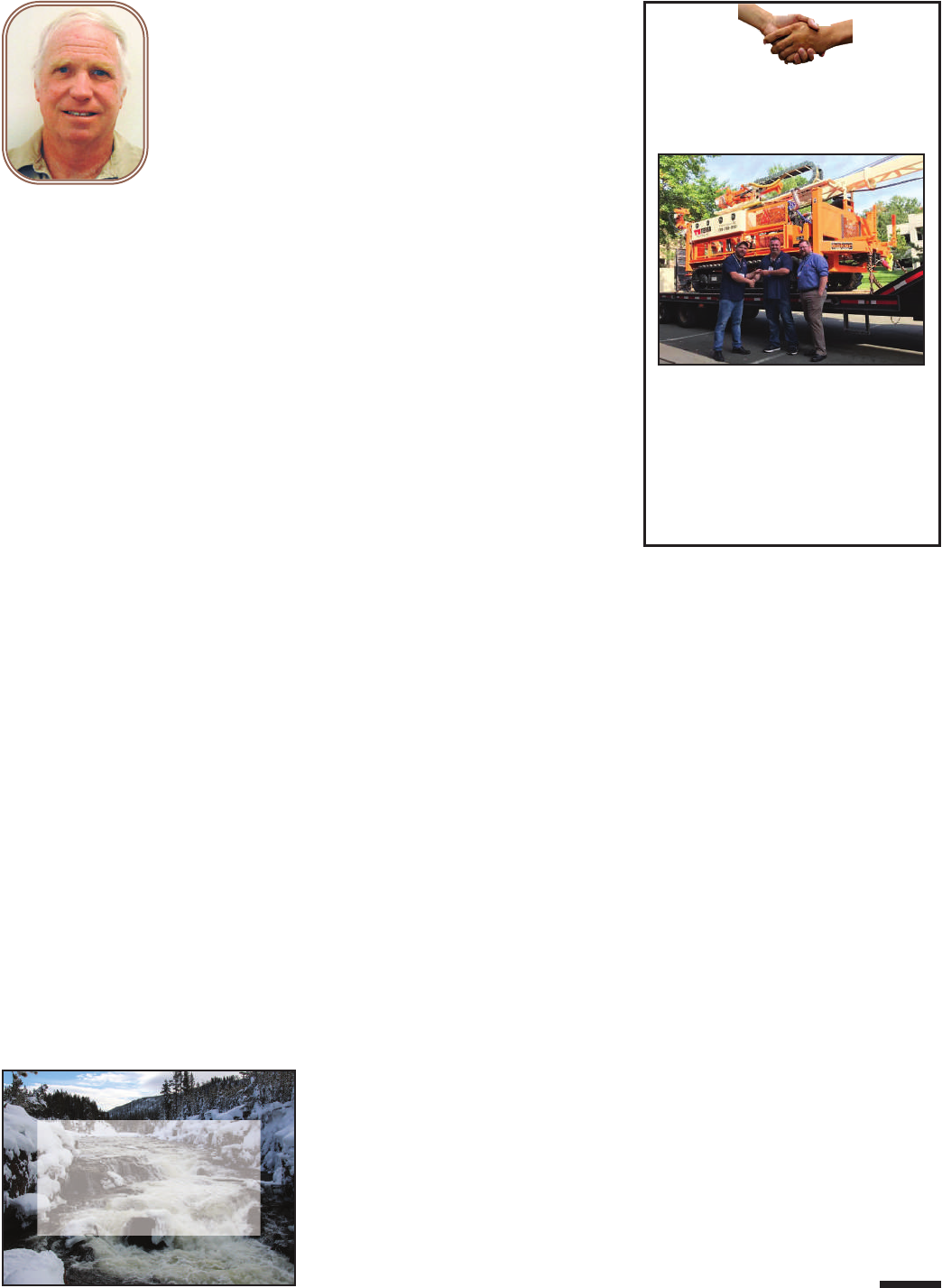

Matt and Joe with Acker Drill Company of

Scranton, Pennsylvania, thanking Eric (C)

w

ith Terra Testing, Inc. of Washington,

P

ennsylvania, for showing their new Acker

Renegade rig at the 2019 National Drilling

A

ssociation event.

Acker Drill Company

Send your deals to:

michele@

worldwidedrillingresource.com

January Issue Deadlines!

Space Reservation:

November 25

th

Display & Classified

Ad Copy: December 1

st

9

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

New Mineral with a Strange Chemical Signature Discovered in a Diamond

Nicole Meyer, a University of Alberta (Canada) student, discovered a new mineral inside a diamond. Named goldschmidtite

in honor of the founder of modern geochemistry Victor Moritz Goldschmidt, it has a curious chemical signature for a mineral

from the earth’s mantle.

“Goldschmidtite has high concentrations of niobium, potassium, and the rare

earth elements lanthanum and cerium, whereas the rest of the mantle is dominated

by other elements, such as magnesium and iron,” explained Meyer, a graduate

student in the Diamond Exploration Research and Training School, part of the

Natural Sciences and Engineering Research Council of Canada’s Collaborative

Research and Training Experience. “For potassium and niobium to constitute a

major proportion of this mineral, it must have formed under exceptional processes

that concentrated these unusual elements.”

Because it’s so difficult to access the mantle, scientists rely on tiny mineral inclusions within diamonds to learn more about

the chemistry deep beneath the earth’s surface.

Meyers said the work to find the new mineral wasn’t hers alone; it was an interdisciplinary collaboration with a mineralogist,

crystallographer, and her advisors.

“This discovery is the result of a lot of patient and meticulous work by Nicole and the research team,” said Graham Pearson,

Meyer’s co-supervisor. “Goldschmidtite is highly unusual for an inclusion captured by diamond, and gives us a snapshot of

fluid processes that affect the deep roots of continents during diamond formation. There have been several attempts to name

new minerals after Goldschmidt, but previous ones have been discredited. This one is here to stay.”

Image courtesy Nicole Meyer.

&DUROLQH6WUHHW

3XQ[VXWDZQH\3$

:HE6LWHKWWSZZZVWDULURQZRUNVFRP

(PDLOVDOHV#VWDULURQZRUNVFRP

)$;

To be noticed,

give us a call: (850) 547-0102

or e-mail: wwdr@

worldwidedrillingresource.com

ZZZURFNPRUHLQWOFRP

12 NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The Un-Comfort Zone II

by Robert Evans Wilson, Jr.

There Is No Such Thing as Greed

Three and a half years ago, in this column, I wrote an article titled: There’s No Such Thing as Being

Stubborn [May 2016,

WWDR

WWDR]. It has been one of my most controversial works, and most read. In it, I

stated that “stubborn” is a nonword like “greed.” I will now follow up and explain why I say the word

“greed” is phony.

Have you ever called someone greedy? Have you been accused of greed? Here is the definition of

GREED according to the American Heritage

®

Dictionary: noun. An excessive desire to acquire or possess more than what one

needs or deserves, especially with respect to material wealth.

Greed, then, is just desire with the added adjective - excessive. Wait a minute - isn’t this what we call ambition? So, who

determines what level of excessive desire becomes greed? Is it like U.S. Supreme Court Justice Potter Stewart’s description

of hard-core pornography: “I’ll know it when I see it?” That’s not only vague, it’s completely subjective, and a frightening standard

on which to determine the law of the land.

American Heritage goes on to say, “possess more than one needs.” Another subjective standard. Who determines how much

someone needs? Then it says, “possess more than one deserves.” Now we are getting somewhere. How can someone acquire

more than they deserve? No one is going to give someone more than they deserve. No one is going to pay more for something

than they think it’s worth. This means the person who gets more than they deserve must have done something ne-farious to get

it, such as swindling, extortion, cheating, or some other form of chicanery. In other words, greed boils down to one thing: theft.

But, you say, greed is the motivation behind stealing. I say, the reason people steal varies greatly. They might be hungry,

on drugs, unemployed, or not smart enough to get a job. I can’t read a person’s mind to determine why they steal, I can only

observe that they do.

If you call someone greedy, you are, in essence, calling them a thief. However,

if they haven’t stolen anything, then they have not taken more than they deserve.

Wilson cont’d on page 52.

13

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

January 28-30, 2020 Fort Worth, TX

UCT is the business event for everyone involved

in maintaining the underground utility pipe infra-

structure. The education program incorporates

trenchless and traditional (open-cut) technologies.

Sessions are taught by industry experts.

• Immersive Learning

• Earn Credit

• Young Professionals Program

• Topgolf Social

• HDD Reunion

• ...and more!

For details, visit uctonline.com and register today!

New and Improved Websites!

Same Great Products,

New Online Experience!

Send your Breaking News announcements to Bonnie@worldwidedrillingresource.com

WHO’S IN THE NEWS

WHO’S IN THE NEWS

The 2018 National Drilling Association

(NDA) Safety Awards were presented at the

recent NDA convention and the winners are:

Terra Testing, Inc.

SANO Drilling, Inc.

Pearson Drilling Company

Breaking News

Breaking News

Additional announcements

from NDA, BESTOLIFE

®

,

Eijkelkamp SonicSampDrill, Dakota

Bodies, Sandvik Mining and Rock

Technology USA, and Danos, are

located in our online issue at:

worldwidedrillingresource.com

Send your Who’s in the News to: bonnie@worldwidedrillingresource.com

DiedrichDrill.com

MilanSupply.com

In Memoriam

Joseph Prentiss “Andy” Anderson, Jr. (1947~2019)

With heavy hearts, the South Atlantic JUBILEE said goodbye to Andy Anderson, who passed away

September 18, 2019. Born Joseph Prentiss Anderson, Jr. in Walterboro, South Carolina, Andy was a graduate

o

f St. Paul’s High School Class of 1965, then served in the U.S. Coast Guard. He was owner of Anderson

Well Drilling in Hollywood, South Carolina, a board member and past president of the South Carolina

Ground Water Association, and board member of the South Atlantic JUBILEE. He also served on the

Meggett Planning Commission for many years. A very active member of West Ashley Independent Baptist Church, Andy was

an elder and assistant treasurer. He loved being involved with his family.

Andy is survived by his wife Rose Marie; daughter Jeanie (Guillaume); son Joseph P. “Jody” Anderson, III (Natalya); grand-

children Joseph P. “Seph” Anderson, IV, and Collin; step-grandchildren Igor and Charlotte; and other extended family.

Charles Thomas “Chuck” Roth (1947~2019)

The

WWDR

WWDR Team was saddened to learn of the passing of Charles Thomas “Chuck” Roth of

Moultonborough, New Hampshire, on September 22, 2019, after a courageous battle with cancer.

Chuck spent his early years in Concord, Massachusetts, before moving to New Hampshire. He grad-

uated from Brewster Academy in Wolfeboro. As a child, he spent many summers in Gilmanton Iron Works.

He was owner and operater of Roth Artesian Well Drilling for over 49 years and took great pride in

taking care of his customers. He had both his fixed-wing and rotor pilot’s licenses and greatly enjoyed

flying his helicopter. He also loved snowmobiling.

Chuck is survived by his children Scott and Shannon; stepchildren Jason and Laura; several grand-

children; and his long-time companion Cynthia.

Gregory G. “Greg” Wragg (1954~2019)

Gregory G. “Greg” Wragg, passed away September 8, 2019, at his home in Ascutney, Vermont. He

was owner of Wragg Brothers Well Drilling with his brother Jay and brother-in-law Bruce. Greg’s passion

was his work. He also enjoyed riding his Harley motorcycle, mowing the lawn, and spending time with

family and friends - especially his “granddogs”.

Greg is survived by his daughter Kelly and son Ryan; his sisters Cheryl and Dedra (Bruce); his brother

Jay; and many nieces and nephews.

Charles Curtis Jenkins (1942~2019)

The New Jersey Ground Water Association sadly reported the loss of Charles Curtis Jenkins on September 18, 2019.

Born in Eccles, West Virginia, Charles moved to Browns Mills, New Jersey, when he was eight, and

thereafter considered himself a lifelong resident. He was owner/president of J. W. Jenkins & Sons Well

Drilling, Inc. and an

active volunteer at

community events.

He was also a mem-

ber of the Pemberton

Twp. Lions Club,

Ne w E g y p t E l k s , a n d t h e M o o s e

Organization.

Husband of the late Dona Jenkins,

Charles is survived by sons Duane,

Todd (Stacy), Bryan (Melinda), and grand-

children Colby, Lola, Zachary, and Sydney.

The

WWDR

WWDR management and staff

extend their sincere condolences to these

water well industry veterans’ families,

friends, and former colleagues.

Lest we forget...

15

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

16

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Demand for Queensland’s Coal Soars

Adapted from Information by the Queensland Resources Council and the Queensland Government

According to the Queensland Resources Council (QRC) in Australia, coal remains Queensland’s biggest export, making

up 40% of the state’s total exports. This high-quality coal is in great demand from Asia and the state’s economy is benefiting

from key trade links with growing economies making coal the central commodity driving exports.

QRC Chief Executive Ian Macfarlane said, “Queensland has an advantage over other states with its close proximity to the

economies of China, India, and Japan. Every quarter we see export data repeating a common theme - the world needs our

metallurgical coal to make steel needed for building modern cities, and our high-quality thermal coal is delivering tomorrow’s

energy needs through high-efficiency, low-emission coal-fired power plants.”

Coal supports more than 215,000 jobs in Queensland and coal exports contributed $36.3 billion to the state’s economy

last year. The resources sector, including minerals, liquified natural gas, coal, and alumina, made up $68.2 billion in total, which

helped Queensland post a record $84.3 billion in exports.

The state recently approved a new coal mine, the Olive Downs mine near Moranbah in central Queensland, which is ex-

pected to create more jobs, coal, and royalties during the mine’s 79-year life. Five hundred jobs are anticipated during con-

struction and 1000 jobs once the mine is operational. The project will include coal handling and crushing facilities at the mine’s

Olive Downs South and Willunga precincts, a rail link to transport coal to the Dalrymple Bay Coal Terminal, a water pipeline,

and power transmission line. Construction is scheduled to begin next year.

“Demand for Queensland coal is very strong. Overseas demand means we are expected to once again sell more than

[220 million tons] of coal,” Macfarlane stated.

M

I

N

Environmental Monitoring

b

y Thomas Kwader, Ph.D., P.G.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Hydrogeologist

Losing Circulation - Usually a Bad Sign

Drilling using circulating fluids has been around for a very long time. Drilling with fluids (mud) allows

us to drill to deep depths and drill large-diameter holes without worrying about a collapse, as long as the

hole is filled with the proper drilling fluid.

Drilling with the proper drilling fluid facilitates the circulation of “mud” to lift the cuttings out of the bore-

hole and “drop” them in a mud pit as the velocity slows down in a “wider” section of the drilling circulation system. The cuttings

settling out in the mud pit are occasionally cleaned out of the pit as the drill bit advances deeper. Circulating fluids have other

benefits, such as keeping the temperature down at the drill bit, retrieving fresh drill cuttings to the surface that reveals the type

of strata being penetrated, and minimizing friction between the drill bit and rod within the borehole. The “weight” and velocity

of the drilling fluid also help lift the cuttings dislodged by the drill bit.

If the drill bit encounters a cavity of a very porous and permeable material, the weight of the drill fluid column may begin to

flow rapidly into the porous borehole wall.

This can develop quickly into a serious

situation for the drill operator and drilling

rig.

Prior to losing circulation, a positive

pressure kept the borehole wide open

and stable. The sudden loss of pres-

sure into the formation or cavity could

allow the borehole and formation near

the bit to collapse and create a void or

depression at the borehole. Even the

most experienced drill operator will be

torn between running away from the

drilling rig and borehole, or to try and

stay with the rig and save the borehole

by increasing the volume of drill mud

headed down the borehole.

At the time the lost circulation first

occurs, there is no way to determine

the size or extent of the events about to

follow. I personally know of at least six

drill operators who were unfortunately

taken to a depth below ground level

and smothered by sediment and soil

falling on top of them.

Prevention techniques include: 1)

Building a wide base or platform beneath

the back of the rig to spread the rig’s

weight over a wider area; 2) Watching

closely for the onset of lost circulation

and cease drilling immediately, and if it

can be done safely, disconnect the last

drill rod from the kelly or tophead drive

and move the rig off the hole.

Tom

Tom Kwader may be contacted

via e-mail to michele@

worldwidedrillingresource.com

17

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

E

N

V

On November 20, 1908, Howard

Hughes Sr. applied for a patent for

his dual-roller bit, which improved

rotary drilling.

by Tim Rasmussen

Water For Life sends containers of equipment and medical supplies to Guatemala each year.

The containers are imported in the name of Agua Para La Vida (APV), our nonprofit sister corpo-

r

ation registered in Guatemala. We must make sure APV is in compliance with all the legal rules

in Guatemala, so there will be no issue when the container hits the port. We have a lawyer in Guatemala City who assists us

with government requirements, and I needed to visit him to make sure everything was ready for the container this fall.

After three flights, including an all-night flight from LAX and a short four hours in a hotel near the airport, I took a TAG

airlines flight to Flores, Guatemala. The plane was an Embraer 110 Bandeirante. This is a 12- to

18-passenger twin engine plane that has been in production about 50 years. There were five of us

onboard, and no door between passengers and pilots. I sat in the front seat and had a good view

of the cockpit procedures; it was very interesting. The ride was bumpy, but uneventful.

The heat and humidity in Petén hit like a wall as I got off the plane. My bag was unloaded

immediately and I was relieved to get in the truck and start the trip to our headquarters in Poptun.

The breeze through the truck window was a relief.

The following day, I had meetings with our SAT accountant (SAT is Guatemala’s version of the

U.S. Internal Revenue Service). He reported he was satisfied we are in compliance with the gov-

ernment regulations and all was in order. Then, I went to a meeting with Dr. Mendez of the Ministry of

Health in Petén. He was happy to hear a container was coming with medical equipment and said he

knew of a couple of villages where there was a great need. I told him we would try to get to them.

I spent the afternoon with Berny going to nearby villages to check on a few pumps. One well is in a beautiful village called

Las Cruses. The people there speak only Q’eqchi’ so communication was difficult, but we found a lady who spoke some

English and she was very helpful. We gave her, a friend, and children a ride to Poptun to the market. They enjoyed the trip

in the truck.

After one more day in Poptun, we needed to go back to Guatemala City for the appoint-

ment with the lawyer. I was treated to a torrential rainfall that night and worried our flight

would be in the rain, but as we got the truck out of

the shop, the rain stopped and we drove to Flores,

then flew back to Guatemala City. This time, Berny

was with me and we took a cab to the hotel.

The appointment at the lawyer’s office was

set for 10 a.m. the following day. Berny picked me

up at the hotel at 9. For about 30 minutes, Berny

wove through streets, making a turn every two or

three blocks. I could never have navigated my

way back to the hotel.

The visit took about 30 minutes. I provided him an authorization for our APV

president, Henry Lazaro, to conduct the business of Water For Life USA in

Guatemala, and he questioned me carefully about our compliance with SAT regu-

lations. He was happy I could report I had just visited with SAT and all was in order

with them. He advised us the corporate status of APV was good and instructed us

to have an APV board meeting as soon as possible and to send him a copy of the

minutes of the meeting signed by the treasurer and president.

I had an 8 a.m. flight back to LAX and wanted to leave in plenty of time

because dealing with traffic in Guatemala City is a serious test of patience. There

are certain times of day when you are better off just to stay wherever you are. What

is normally a 15-minute trip from the hotel to the airport at 5 a.m. becomes a 30-

minute trip at 5:30, and by 6:30, probably an hour and a half, if there are no accidents!

If there is an accident, there’s no telling what will happen or when you will arrive.

The following day, I left the hotel early enough to have a fast trip to the airport,

then three flights back to the good old USA. There is nothing like seeing how it is there

to make one realize how good it is here. It is a perspective everyone should gain.

If you would like to help, contact Gary Bartholomew at 509-466-5075 or 509-939-1941

Tim

Tim Rasmussen may be contacted via e-mail to

michele@worldwidedrillingresource.com

W

T

R

302-684-3197

FAX: 302-384-0643

142 Broadkill Rd. • Milton, DE 19968

www.atlantic-screen.com

email: atlantic@ce.net

Manufacturers of Slotted &

Perforated Pipe ranging

from ½” to 24” diameter

Atlantic

Screen &

Mfg., Inc.

• Well Rehab. Products

• Manholes

• Bentonite

• Filter Sock

• Inline Chemical Mixers

• Sampling Bailers

• Clear PVC Pipe

• Locking Caps

18

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

When it comes to supplying the country with reliable, renewable energy, geothermal technology is a great solution for the

United States, but due to technical and nontechnical issues, only a fraction of its potential has been realized.

The U.S. Department of Energy’s (DOE’s) Geothermal Technologies Office (GTO) recently participated in a multiyear re-

search collaboration with national laboratories, industry experts, and academics to assess ways to increase geothermal energy

deployment through technological improvements, reducing costs, and mitigating barriers. The analysis also assessed the eco-

nomic benefits to the U.S. geothermal industry and potential environmental impacts of increased deployment - including jobs,

consumer energy prices, water use, and air quality - and investigated opportunities for desalination, mineral recovery, and hy-

bridization with other energy technologies for greater efficiencies and lower costs.

The study, GeoVision: Harnessing the Heat Beneath Our Feet includes a road map of items which can help the industry

move toward widespread implementation. The GeoVision analysis reveals the unique characteristics of geothermal energy

and its unrealized potential, including:

j Nationwide energy applications through unique capabilities in electricity generation, as well as residential, commercial,

and district heating and cooling

j Ready-to-use commercial technologies, augmented by developing technologies with vast potential for increased elec-

tricity generation and direct-use applications

j Job impacts

j Revenue potential for federal, state, and local stakeholders, as well as royalty potential for leaseholders.

The analysis also used a suite of modeling tools and scenarios to evaluate the performance of geothermal technologies

relative to other energy technologies. The analyses included evaluating the potential role of existing and future geothermal

deployment in both the electric sector and the heating and cooling sector, as well as unconventional geothermal resources

like enhanced geothermal systems, or EGS. In the heating and cooling sector, the analysis modeled geothermal heat pumps

(GHPs), which are also known as ground source heat pumps, and distric heating systems (using both conventional and EGS

resources).

Key findings of the analysis include technology improvements which could reduce costs and increase geothermal electric

power deployment. Improving the tools,

technologies, and methodologies used to

explore, discover, access, and manage

geothermal resources could reduce both

the costs and risks associated with geo-

thermal developments which could poten-

tially increase geothermal power generation

by 2050. Additionally, the analysis sug-

gests improving permitting timelines could

be another step in reducing the costs asso-

ciated with geothermal project development,

potentially doubling installed geothermal

capacity within the same time frame.

America’s Underappreciated Energy Source

Adapted from Information by the U.S. Department of Energy

GE

O

Sunset over the DOE geothermal test site in Fallon, Nevada. Photo by Dick Benoit courtesy of the U.S. Department of Energy.

Information: Joel Walton

jwalton022@aol.com • (225) 744-4554

www.lgwa.org

January 9, 2020

Paragon Casino - Marksville, LA

Tower or Atrium hotel rooms call (800) 642-7777 and refer to

LGWA Annual 2020 conference use code

LGWA 01G

Registration starts at 7 am, Seminars start at 8 am

(Cocktail hour, dinner, and BINGO at 6 pm

the night before the convention [the 8th].)

LLoouuiissiiaannaa GGrroouunndd WWaatteerr AAssssoocciiaattiioonn

LLoouuiissiiaannaa GGrroouunndd WWaatteerr AAssssoocciiaattiioonn

CCoonnvveennttiioonn && TTrraaddee SShhooww

CCoonnvveennttiioonn && TTrraaddee SShhooww

20

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

A four-year old asks an

average of 437 questions a day.

21

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

Five Ways to Battle Insider Threats

A

dapted from Information by CONEXPO-CON/AGG 2020

A recent study on insider threats offered some shocking information. The study indicated how compromising an insider is

a lot easier for your rival than actually breaking in from the outside, and attention to this problem is well below where it should

be.

While 40% of those surveyed rated insider threat as the most damaging, nearly the same percentage (38%) said they

don’t have a way to detect insider threats. What’s worse, roughly 20% don’t have a plan in place to mitigate damage from this

type of incident.

There are some fairly simple ways to protect your company from both malicious and unintentional insiders, including:

1 - Controlling or eliminating e-mail attachments and links. E-mails are the

number one way for outsiders to attack companies in today’s digital era.

Although the message itself isn’t dangerous, links and attachments are.

Several security companies offer malware assessment of links and attach-

ments. Suspicious attachments are quarantined and dangerous links are dis-

abled.

2. Properly manage and control access to data and critical systems. Work with

your human resources team and business managers to understand employee

roles and the type of data access they need to do their jobs. Then, assign only

the necessary access level, no more.

3. Know where your data is. An important issue is to know where critical and sensitive data is located in your system so

it can be locked down when necessary. If you don’t know where this information is, how can you protect it?

4. Monitor employee behavior and look for irregularities, including action monitoring software. It’s not intrusive to look for

excessive data dumps or repeated attempts to look at files or directories which are not permitted - it’s good business.

Educate employees to be on the lookout for behavioral changes in coworkers.

5. Raise security awareness. Lastly, but perhaps more importantly, is the need for security awareness training. This

should be an essential part of your company’s culture - not an afterthought or checklist item. Companies partnering with

their employees to ensure security awareness do better than those which force compliance, or simply perform training to

check a box.

Although most attacks may come from outside your organization, the most serious damage is done by insiders with

unchecked access to your information.

22

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

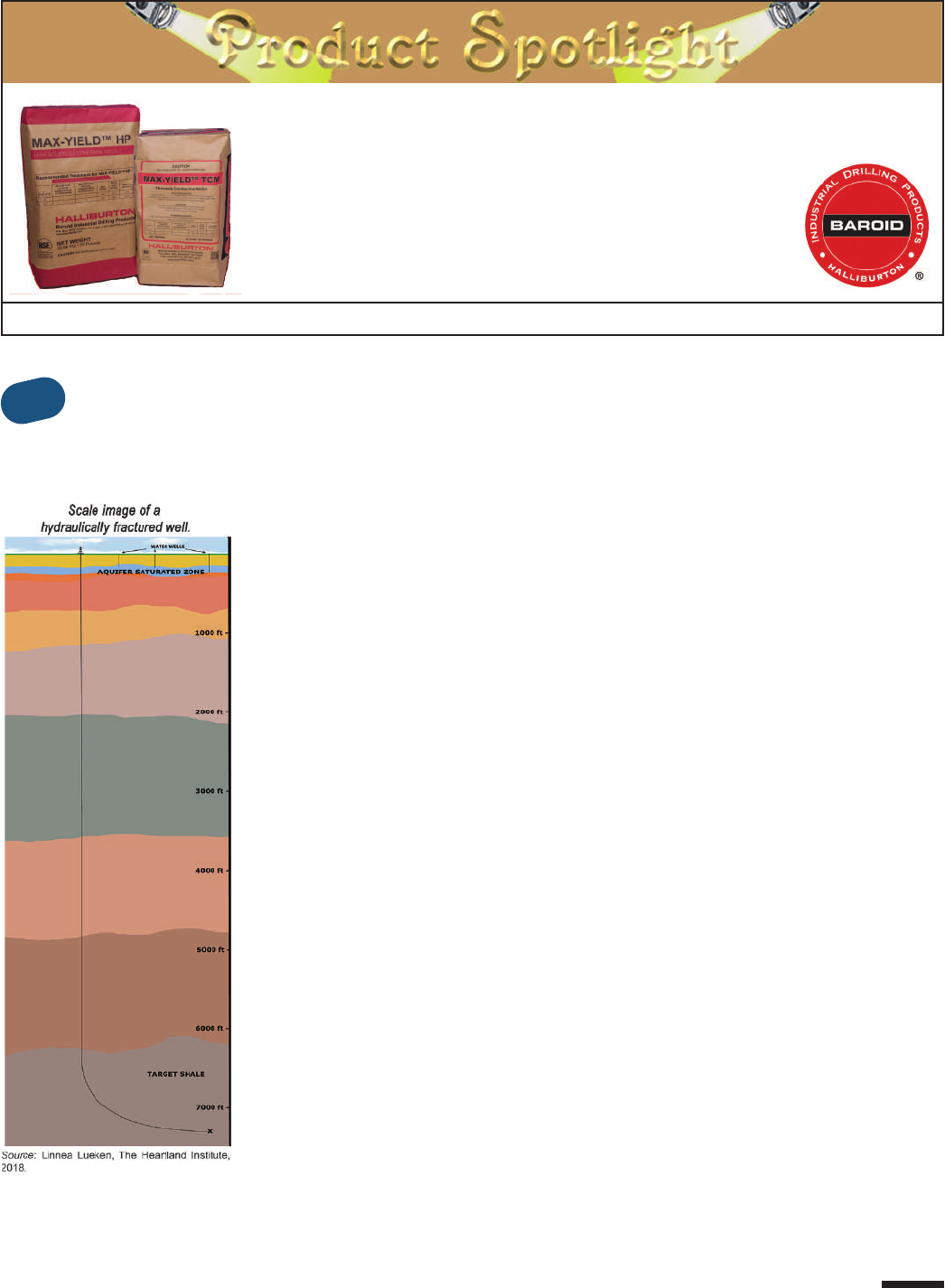

Baroid Industrial Drilling Products’ new MAX-YIELD™ is a one-to-one ratio geo-

thermal system that can reduce logistics, transportation, and handling costs compared

to traditional grout designs that use two or more sacks of grout to a single bag of

thermally conductive media.

MAX-YIELD™ provides a stable grout with low permeability and

e

nhanced subsurface heat transfer in ground source heat loops. It

is easily mixed and pumped in a uniform slurry, and meets solids

content of >20% solids.

To adjust thermal conductivity, simply adjust the volume of makeup

water used.

Baroid Industrial Drilling Products is a Valued

WWDR

WWDR Advertiser.

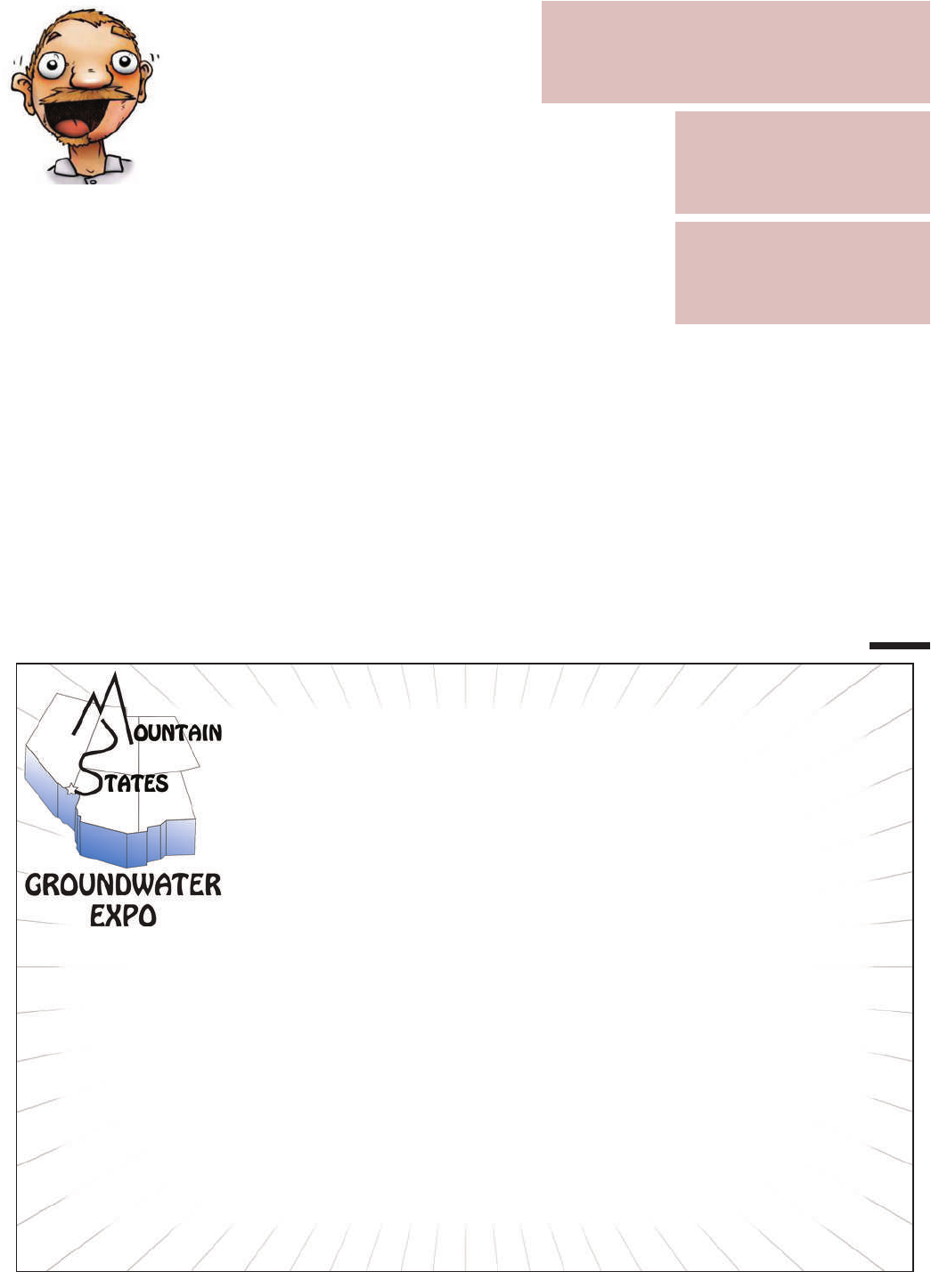

Dispelling the Myths Surrounding

Hydraulic Fracturing Part 1

Adapted from a Policy Brief by The Heartland Institute

Hydraulic fracturing is a method to help extract natural gas and oil located several miles beneath the earth’s surface. Over

the past decade, this process has increased the output of natural gas by 40% and oil produc-

tion by 85%. Additionally, the hydraulic fracturing industry now supports nearly three million

U.S. jobs.

Unfortunately, its well-documented success has gone unnoticed and is not appreciated

by the public. In fact, the process has been demonized and is often attacked by lawmakers

because of false claims by opponents. In this series of articles, we will take a look at the most

popular myths about hydraulic fracturing and take a look at, and review the facts.

Myth #1 - Hydraulic Fracturing Pollutes Our Water - Perhaps one of the most preva-

lent myths, this claim was spurred by a video of a man in Colorado lighting the water from his

home faucet on fire. Not only was it scary to watch, it also had a powerful impact on the public.

However, when scientists examined the case a little closer, the facts told a different story. The

Colorado Oil and Gas Conservation Commission tested the man’s water and, by analyzing

the istopic composition of the gas, they were able to determine the source of the methane

present in his water. It turns out, biogenic, naturally occurring methane was the culprit, not

hydraulic fracturing. In fact, the water well did not test positive for any of the chemicals used

in the fracturing process.

Since 2010, there have been more than two dozen peer-reviewed studies and assess-

ments, all showing hydraulic fracturing is not a significant threat to groundwater sources, in-

cluding drinking water.

Perhaps the most compelling piece of evidence is the U.S. Environmental Protection

Agency study released in 2016. This $29 million project studied the impacts on groundwater

by 110,000 hydraulically fractured wells across the country since 2011. The six-year report

concluded: “Hydraulic fracturing operations are unlikely to generate sufficient pressure to

drive fluids into shallow drinking water zones.”

Why is hydraulic fracturing unlikely to contaminate groundwater sources? During the frac-

turing process, fissures located thousands of feet below the water table are opened by pump-

ing fluid solutions at high pressures, forming small fractures in the rock. Proppants, mostly

sand, are pumped into the fissures to prevent them from closing. While the hydraulic pressure

is enough to crack the rock, it is not enough to send fluid up through multiple rock formations,

where drinking water zones are located.

It’s also important to remember, drill operators don’t want water in their gas and oil wells.

Water intrusion could change the drilling mud weight and lead to disaster. Drilling mud helps

maintain stable pressures underground, lubricates the bit, and brings cuttings to the surface.

If water gets into the well, the mud weight changes, which in turn, causes the pressure at the bottom of the well to change. If

not brought under control, the insufficient mud weight could cause a blowout.

We’ll dive into Myth #2 next month.

G

&

O

February 6 - 7, 2020

Aquarius Casino Resort - Laughlin, NV

Located on the Colorado River

For more information visit us online: mountainstatesgroundwater.com

E-mail: info@mountainstatesgroundwater.com

(480) 609-3993

WHY ATTEND???

•It’s a great opportunity to visit with manufacturers &

suppliers, drilling contractors & pump installers, technical

& consulting firms, state groundwater officials, etc.

• Attend the seminars

• Visit the exhibits

• Earn CEU’s

• Participate in the Buck Lively Scholarship Auction & Raffle

No membership is required to attend – Everyone is welcome!

It’s casual & inexpensive: Bring your employees!

24

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The “Idiots” Corner

b

y “Billy Bob Smith”

This has been on my mind for longer than I

care to admit - stuff other people do, say, believe,

etc. that I just don’t get, can’t stand, or drives me nuts. Yes, yes, I

get it - I have my quirks just like everyone reading this article, but I

ask you - do you think some other people’s quirks are worse, more

difficult, more idiotic than some of your own? First, here’s a couple

of quotes [in the boxes] from a few famous people - yes, I am including myself in that cat-

egory. Now, the following is a very short list of just some of the quirks friends, relatives,

kids, customers, or bosses have had over the years:

You bite your fingernails/pick your nose. You hate the overuse of the word “like”.

You chew with your mouth open. You hate gum “crackers”.

The more people there are, the more quiet you are.

You get extremely defensive when someone disagrees with you.

You overexaggerate when telling stories of your past deeds. You hate your neighbors’ barking dogs.

Whenever you cry, you try to catch the tears with your tongue. You get upset when kids act up in a public place.

You panic when you are suddenly put into the spotlight. You adjust your glasses when you’re nervous.

You cannot stand the sound of people snapping their fingers.

You’re extremely conscious of proper posture and you’re constantly standing or sitting up straight.

You absolutely REFUSE to sleep without a trinket of some kind (a blanket, stuffed animal, pillow, etc.).

Every time you sit near a candle, you try your best to put it out with your fingers and are rarely successful.

You are embarrassed by the sound of your laugh, and use all your willpower to not let a single giggle escape.

You just can’t stop talking about your preferences - you always have to give your opinion, even total strangers.

You never look directly into someone’s eyes, instead gazing slightly to the right or left of their face when speaking to them.

You always need to look cool. You obsessively map out dramatic entrances, witty one-liners, and elaborate combat moves.

You zone out when another takes longer than five seconds to explain something, but pretend to have understood it perfectly.

Okay, now it’s time for you to create a personal list of your quirks. Want to make it a real fun experiment? Share your list

with a spouse, significant other, or boss, then ask for their reaction.

Billy Bob Contact him via e-mail to michele@worldwidedrillingresource.com

“

However my parents - both of whom came from im-

poverished backgrounds and neither of whom had

been to college, took the view that my overactive imag-

ination was an amusing quirk that would never pay a

mortgage or secure a pension.”

J. K. Rowling

“Be happy with being you. Love

your flaws. Own your quirks. And

know that you are just as perfect as

a

nyone else, exactly as you are.”

Ariana Grande

“Everyone is quirky in their own

unique way. The question is - can

we accept other’s quirks as okay,

a

s we expect others to accept ours

as okay?”

Billy Bob

Frequently-Used

Geological Terms

Part 85

G

lossary Adapted from the

Dictionary of Geological Terms

R

Rock Salt - Coarsely crystalline halite

occurring as a massive or granular

aggregate, and constituting a nearly

pure sedimentary rock which may occur

in domes, plugs, or as extensive beds

resulting from the evaporation of saline

water. Also refers to artificially prepared

salt in the form of large crystals or

masses.

Rockslide - The downward and usually

rapid movement of newly detached seg-

ments of bedrock, sliding on a surface

of bedding, jointing, or faulting. The

moving mass usually breaks up into

several small pieces.

Roof - Rock lying above a coal bed or the back above an ore body. Also used to describe rock bordering the upper surface

of an igneous intrusion.

Roof Pendant - A downward projection of native rock into an igneous intrusion.

Roof Rock - A shale or other impervious rock which acts as a barrier to the movement of gas or oil. It overlies a reservoir rock

to form a trap.

Room and Pillar - A form of mining where the ore is mined in rooms separated by pillars of undisturbed rock left as roof support.

Rose Quartz - Quarts with a rose-pink color, used as a gem or an ornamental stone.

Rosette - A radially symmetrical, sand-filled crystalline aggregate

or cluster which resembles a rose, formed in sedimentary rocks by

barite, marcasite, or pyrite.

Rotary Drilling - The main method of drilling deep wells, especial-

ly gas and oil wells. A hard-toothed drill bit at the bottom of rotating

drill pipe grinds a hole in the rock. Lubrication and cooling are pro-

vided by continuously circulating drilling mud, which also brings

well cuttings to the surface.

Rotary Table - In rotary drilling, a power-driven circular platform

on the derrick floor which rotates the kelly, drill pipe, and drill bit. It

is sometimes used as the zero depth reference for downhole

measurements.

Rubellite - A pale rose red to deep ruby red transparent lithian

variety of tourmaline, used as a gemstone.

Ruby - Red variety of corundum containing small amounts of

chromium, used as a gemstone.

Rudaceous - A sedimentary rock composed of a significant

amount of fragments coarser than sand grains; pertaining to a rudite. Also said of the texture of such a rock.

Rudite - A general name used for consolidated sedimentary rocks composed of rounded or angu-

lar fragments coarser than sand, such as granules, pebbles, cobbles, boulders, and gravel.

Run-of-mine - Said of ore in its natural, unprocessed state; pertaining to ore just as it is mined.

Rutilated Quartz - Quartz characterized by the presence of enclosed needlelike crystals of rutile.

Rutile - A reddish-brown tetragonal mineral. It is trimorphous with anatase and brookite, and

often contains a little iron. Rutile forms prismatic crystals in other minerals; it occurs as a primary

mineral in some acid igneous rocks, metamorphic rocks, and as residual grains in beach sands.

It is an ore of titanium.

R Wave - Stands for Rayleigh Wave which is a type of surface wave having a retrograde, elliptical

motion at the free surface.

25

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

Visit us at NGWA Booth 1425

Visit us at UCT Ft Worth Booth 801

Steve Wageman Global Industrial Sales: swageman@bestolife.com

WHAT ALL THE BUZZ IS ABOUT!

F

or more than 80 years, BESTOLIFE

®

p

remium compounds have lead the market

for drilling, production, and industrial applications. We offer a diverse lineup of

superior lubricants proven to extend the life of drill pipe and equipment, and

increase efficiency for contractors on the toughest and most demanding drilling jobs

with premium thread compounds for oil and gas industry, horizontal directional

d

rilling (HDD) compounds, and water well and industrial compounds. All of our

products are formulated and manufactured according to the strictest standards

of quality to assure our compounds meet or exceed industry requirements and

customer needs. Our perpetual commitment to quality and research ensures

every BESTOLIFE compound...

Applies Like Honey, and Works Like a Bee!

(214) 583-0343

bestolife.com

That’s

it for R words,

we’ll start S

next month!

G

&

O

WWDR

WWDR photo of a cluster of gypsum rosettes.

Nitrate Coated Premium Liners

5x6, 5x8, & 5x10 Gardner Denver

5-1/2x8 & 5-1/2x10 Gardner Denver

7-1/2x8 & 7-1/2x10 Gardner Denver

New Pumps In Stock

Gardner Denver 4x5 TEE Triplex.

Gardner Denver 5-1/2x5 TEE Triplex

Gardner Denver 4x5 or 4-1/2x5 Duplex

Gardner Denver 5x6 Duplex

Gardner Denver 5x6 Air Drive Duplex

Gardner Denver 5x8 Duplex

Gardner Denver 5-1/2x8 Duplex

Gardner Denver 7-1/2x8 Duplex

Gardner Denver 7-1/2x10 Duplex

Gardner Denver 5-1/2x5 THE Triplex

Gardner Denver 5x8 PAH Triplex

Call for Prices.

We Have a Variety of Brands

of Mud Pump Parts and

Power Units in Stock.

Special or Obsolete Parts Made to Order.

Cash for Surplus

Mud Pumps

.

Rebuilt Mud Pumps

4-1/2x6 Gaso Duplex

4-1/2x6 Oilwell Duplex

Gardner Denver 4-1/2x8 PA-8 Triplex

Gardner Denver 5x6 Duplex

Gardner Denver 5x10 Duplex

Gaso 5x10 Duplex

OVER 300 PUMPS IN STOCK

Armstrong Machine Co. Inc.

Pocahontas, IA 50574 USA

712-335-4131 ~ 24 Hours 7 Days a Week • Fax: 712-335-4565

800-831-4527 USA & Canada (8AM to 4PM Monday-Friday)

armstrongmachine.com

amci@armstrongmachine.com

Hydraulic Grout Pumps 5”, 6”, & 7-1/2”

Rods Heat-Treated & Chromed

5x6, 5x8, & 5-1/2x8 Gardner Denver

5x10 & 5-1/2x10 Gardner Denver

7-1/2x8 & 7-1/2x10 Gardner Denver

26

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

In Memoriam

Thomas Boone “T. Boone” Pickens, Jr. (

1928 – 2019)

Born in Holdenville, Oklahoma, May 22, 1928, Thomas Boone “T. Boone” Pickens, Jr. was the

son of an oil landman. When he was young, his family moved to Amarillo, Texas, where he grew

up and attended high school. After one year at Texas A&M University, he transferred to Oklahoma

A&M (now Oklahoma State University), where he earned a degree in geology in 1951. Pickens

worked for Phillips Petroleum for three years before striking out on his own in 1954. With $2500

of borrowed money, Pickens and two investors formed an oil and gas firm called Petroleum

Exploration Inc., as well as another company Altair Oil & Gas Co., to pursue oil and gas exploration opportunities in western

Canada. Then he established Mesa Petroleum, which he took public in 1964. Pickens turned Mesa into one of America’s

largest independent natural gas and oil companies with the company producing more than 3 trillion cubic feet of gas and 150

million barrels of oil between 1964 - 1996. He was an advocate for energy independence in the U.S.

This self-made oil tycoon never forgot his humble beginnings, he said, “For most of my adult life, I’ve believed that I was put

on earth to make money and be generous with it. I’ve never been a fan of inherited wealth.” He gave more than one billion dollars

to philanthropic and educational causes including his alma mater Oklahoma State University, the University of Texas Southwestern

Medical Center, the University of Texas MD Anderson Cancer Center, the Center for BrainHealth at The University of Texas at

Dallas, Scottish Rite Children’s Hospital, the T. Boone Pickens Hospice and Palliative Care Center, the Wilmer Eye Institute at

Johns Hopkins University, Big Brothers Big Sisters of North Texas, the Center for Missing and Exploited Children, the Fisher House

Foundation, Happy Hill Farm, Jonathan’s Place, Meals on Wheels, the World Cranial Foundation, The Senior Source, USO

Dallas/Fort Worth, Special Olympics of Texas, and Jubilee Park (an inner-city Dallas community).

He penned a letter to be published after his death (it’s inspiring and worth reading on LinkedIn.com

) which offers sage

advice and insight into what he believed were the keys to his success including, a good work ethic; learning from your mistakes; being

humble; embracing change; having faith in spiritual matters and in humanity; staying fit; and not blaming others when you fail.

He ends his letter with this, “I left an undying love for America, and the hope it presents for all. I left a passion for entrepreneurship,

and the promise it sustains. I left the belief that future generations can and will do better than my own. Thank you. It’s time we

all move on.”

T. Boone Pickens passed away on September 11, of natural causes. He is survived by his children Deborah, Pam, Michael,

Tom, and Liz, as well as 11 grandchildren, and an increasing number of great grandchildren. The T. Boone Pickens Foundation

will continue to support the many charitable endeavors he embraced during his life.

Determining the Correct

Drill for Your Project

Adapted from Information by the

Association of Equipment

M

anufacturers

Drill rigs are used in a wide variety

of applications. Among them, construc-

tion drill rigs are high-performance,

technologically advanced, and well-suit-

ed for multiple applications.

Larger drill rigs are used for mining,

exploration, geotechnical, and construc-

tion projects. They can also be used to

drill wells (water, oil, and natural gas),

sample subsurface materials, and install

subsurface fabrications, such as under-

ground utilities. According to Jeff Calow,

technical sales representative, foundation

and surface drilling for Selix Equipment,

a dealer for both Soilmec and Sandvik

drills, “In a shoring or caisson installa-

tion scenario, depth, diameter, and the necessity for segmental casing to line the hole will dictate the size and type of the

machine. Larger diameter and deeper holes will require larger machines with greater torque and larger winch capacities,

allowing a greater amount of material to be extracted from the shaft.”

Smaller machines are often chosen for limited-access projects and offer decreased mobilization costs, better more efficient

fuel consumption, and a smaller labor force. “Access is of course always a consideration as a machine physically fitting on a

jobsite is only half the battle - you often need a greater lay down area available on-site for the assembly and disassembly of

the machine,” stated Calow.

Drills are engineered in one of two different configurations: rotary and percussion. Percussion is used to hit rock which is

too hard to put an auger through. Augers pull the earth out as you are drilling, which is great in soft soil, but once you hit harder

materials, you will need a percussion drill.

Rotary drill systems use a lower rotary drive to advance casing through unconsolidated overburden and, where applicable,

socket the casing into bedrock. The drill string is equipped with either a down-the-hole (DTH) hammer or a rotary bit to remove

material and bring it to the surface.

There are also several drilling head options to consider. The application and material being drilled will determine which is

best for your project. “If it is hard rock or soft rock, does it have clay in it? This will determine the flushing characteristics and

the type of carbide used,” said Wes Vietmeier, business line manager underground drills, Sandvik Mining and Rock Technology.

“Also, the type of drilling equipment the customer has will be a factor: percussion drilling, DTH, top hammer, rotary, or auger

drilling. The drilling depth and hole size will also affect the choice of bits.”

For foundation drilling, the most popular construction application for a drill, there are five categories of drill heads:

Earth/Soil Augers - Used in softer ground conditions, such as clay, sand, or till, earth augers have a spade-style tooth,

similar to what an excavator bucket uses.

Rock Augers - This style of auger uses a bullet-style round shank carbide

tooth for drilling in harder ground conditions, typically when conditions exceed

the hardness of clay.

Core Barrels - Core barrels also use a bullet-style round shank carbide tooth,

but occasionally they can be found using pin-on or weld-on carbide bars/teeth.

This is used when an obstruction cannot be passed up the flights of a standard

auger, or the obstruction is simply too large and must be cored through. Core

barrels pickup where rock augers leave off.

Drilling Buckets - Available in earth (spade teeth), rock (bullet teeth), and

cleanout designs (flat edge), drilling buckets work either as a centrifugal bucket

with a swinging door plate on the bottom or as a double-action centrifugal with a plunger actuated fall away door plate on

the bottom. Drilling buckets are used to excavate material when the shaft is saturated in water, or when drilling with sus-

pension slurries or polymers.

Continuous Flight Auger (CFA) - This auger is actually designed to drill the entire length of the hole in one shot. The

stem of the auger is hollow with a port on the bottom of the auger, which allows concrete to be pumped through the auger

when the desired depth is achieved. This creates a stable shaft, as material is only removed during the concreting phase.

CFA does not work in hard rock or in earth containing numerous obstructions.

By knowing the features of each kind of drill, as well as work site drilling conditions, you can choose a drill which is best

for your specific construction site.

28

NOVEMBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

C

&

G

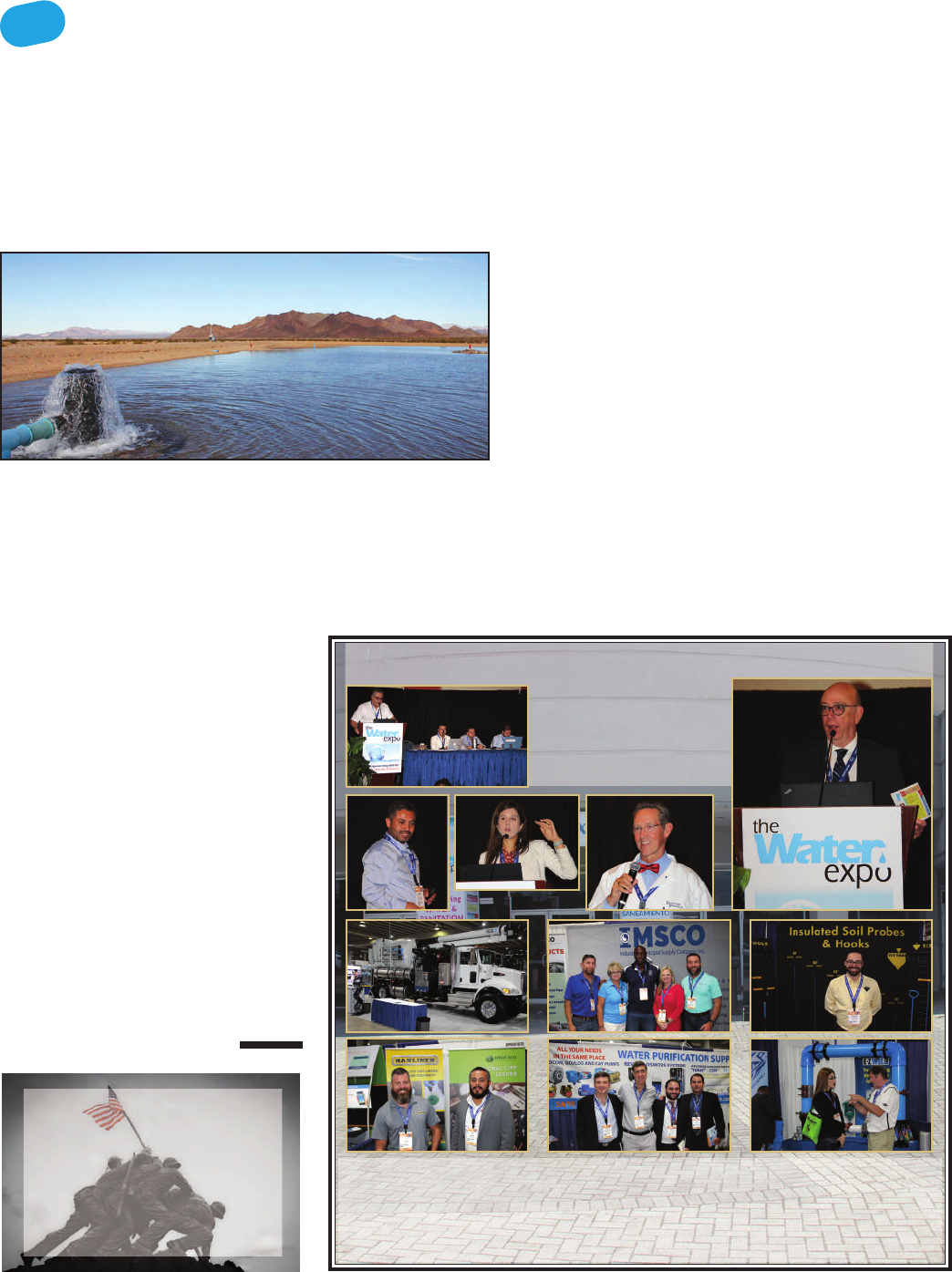

Quality Built from Experience

888-300-2220

www.tdhmfg.com

The perfect combination of lightweight and

durable. The 3X2 is built to handle the pressure

of a pump hoist twice its size, yet agile so

any job can be done quick and efficient.

Available on a flatbed or service body with

an available 3-part upgrade to 9000 lbs, the

3X2 is a contractor’s dream.

Available Now!

29

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

NOVEMBER 2019

Using Geomagnetic Data to Improve MWD Operations

Adapted from Information by CGG

Based in France, CGG is a geoscience company which collects, processes, and interprets geophysical data and provides

advice to clients in the mineral, gas and oil, engineering, and environmental management industries, based on the results.

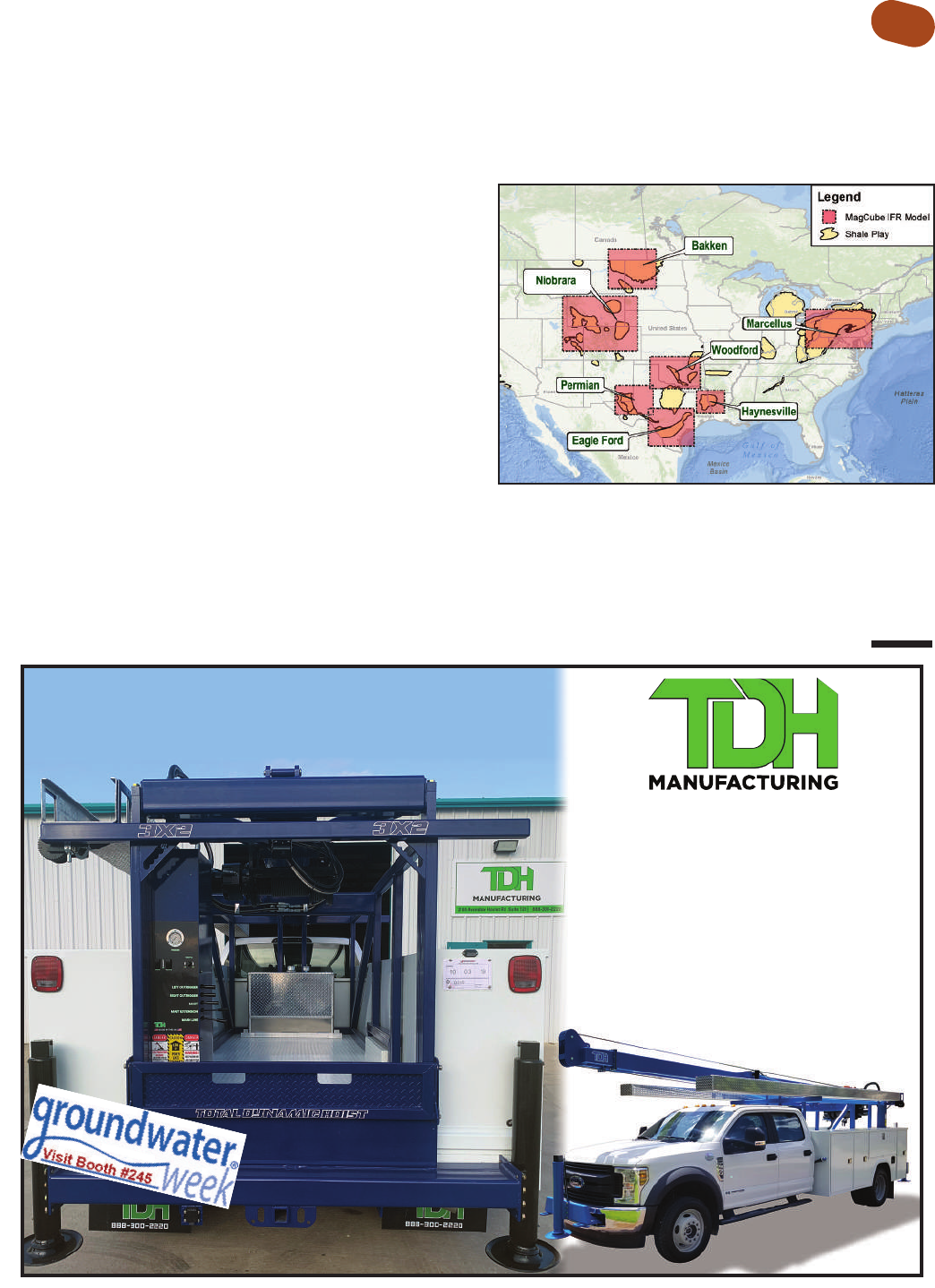

Recently, the company announced the availability of precalculated MagCube™ in-field referencing (IFR) models for meas-

urement while drilling (MWD) surveys over seven U.S. onshore basins and plays: Bakken, Eagle Ford, Haynesville, Marcellus,

Niobrara, Permian, and Woodford.

CGG’s MagCube magnetic referencing system combines a

global geomagnetic reference model with local magnetic survey

data to deliver declination (dip), inclination, and total field values

at depth. These cubes of subsurface vector magnetic field infor-

mation will help with MWD surveys for directional drilling.

Accurately knowing a well’s trajectory while the well is still being

drilled could save costly sidetracks, and even prevent collisions

with other wells in tightly drilled shale plays. The MagCube models

include an estimation of positional uncertainties, allowing clients

to design more closely spaced drilling programs.