NNeeeedd aa rriigg??

CCaallll JJeeffff!!

PPhhoonnee:: 882288--332222--33005566 FFaaxx:: 882288--332222--44004422

22551155 HHiigghhwwaayy 7700 SSWW HHiicckkoorryy,, NNCC 2288660022

EE--mmaaiill:: jjeeffffjj@@ddrriilllliinnggeeqquuiipp..ccoomm

wwwwww..ddrriilllliinnggeeqquuiipp..ccoomm

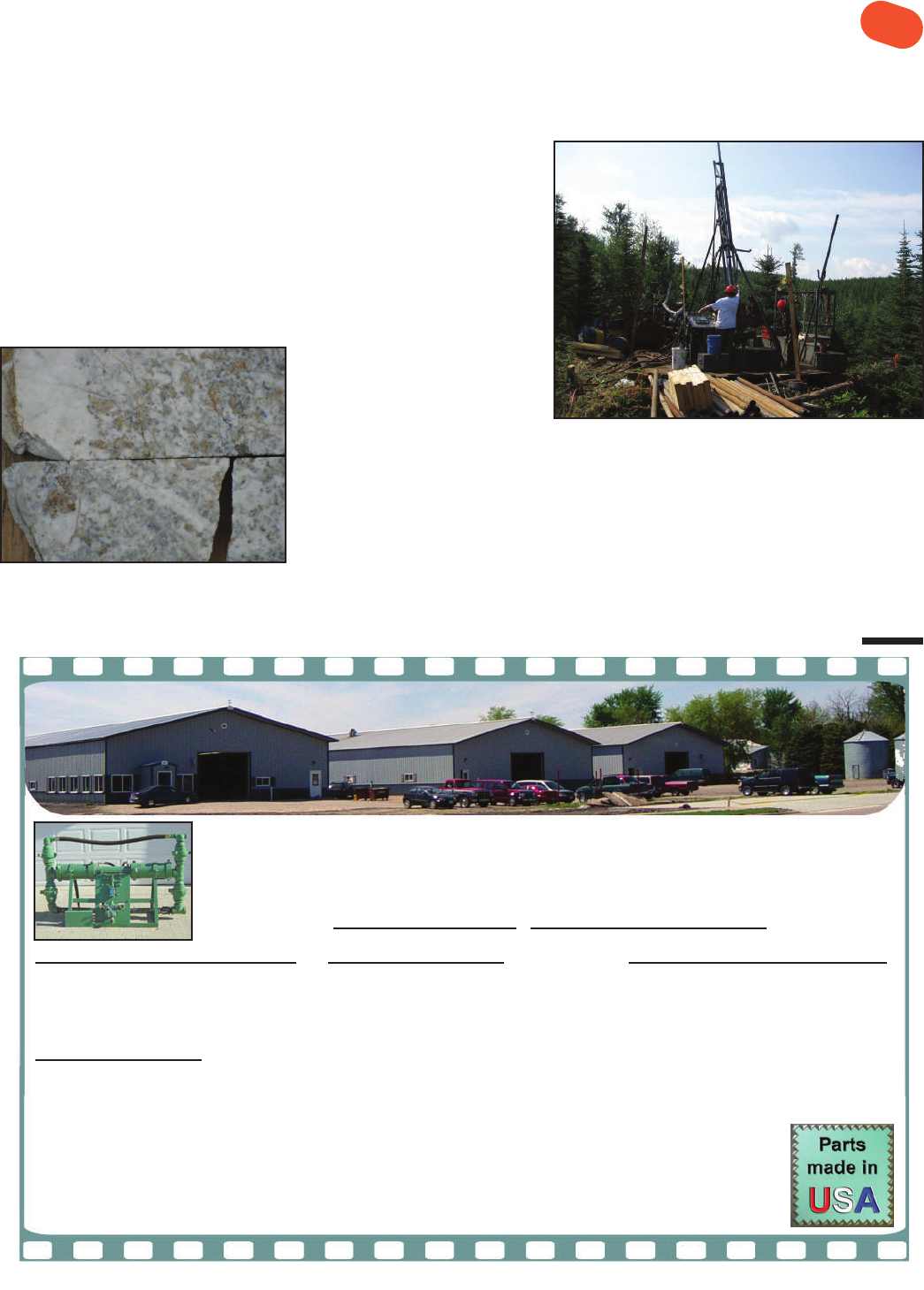

Single & Double Hopper

Rose-Wall Grouters

Rose-Wall Water Truck

Pulstar P12000

Pulstar P8000 Pulstar P12000

Pulstar P10000

Pulstar P10000

mounted on a Dodge 5500

Pulstar P7000

Volume 15October 2019

Breaking News..................................................................13

Classified Section:

WorldWide SUPER MART™

WorldWide SUPER MART™..................50-64

Dealmakers........................................................................35

Education Connection......................................................19

Fun Page............................................................................32

Hot Off the Press.................................................................9

Industry Announcements.................................................36

Obituary: Gross, Kenneth Richard “Ken”.......................26

Obituary: Purchase, A. Richard “Rick”...........................26

Obituary: Thomas, Rick L.................................................20

Photo Gallery......................................................................38

Product Spotlight..............................................................14

Where are you planning to go?........................................46

Who’s in the News.............................................................13

WorldWide Association Memberships

WorldWide Association Memberships................................27

WorldWide Business Directory™

WorldWide Business Directory™.............................10,11,12

WorldWide

WorldWide

.........6

Editorial Focus for October - Geothermal

C&G

DIR

ENV

EXB

G&O

GEO

MIN

WTR

Allegheny Instruments........................................................46

America West Drilling Supply..............................................61

Armstrong Machine Co., Inc. (AMCI)..................................33

Atlantic Screen & Manufacturing, Inc. (ASI)........................45

Baker Water Systems.........................................................44

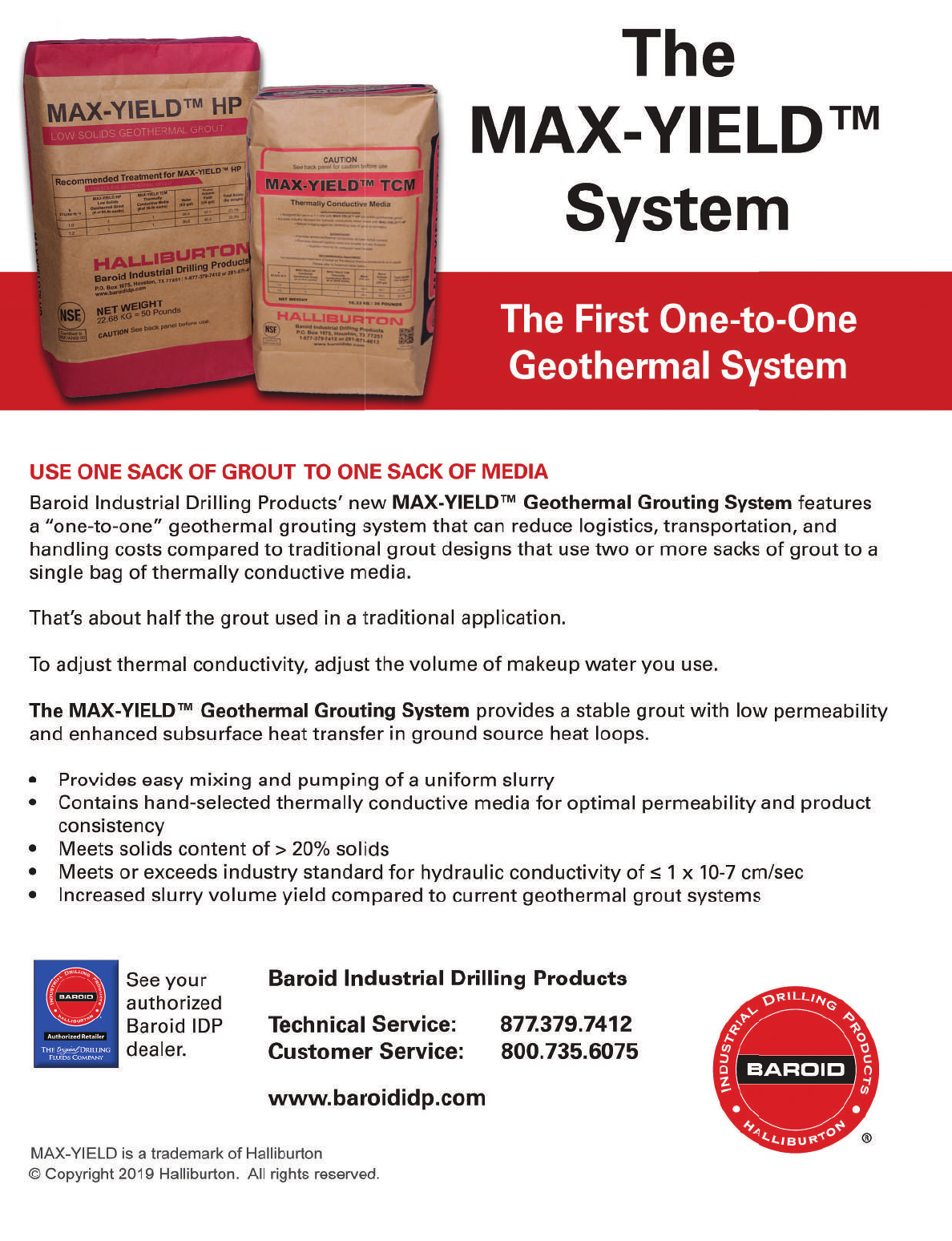

Baroid Industrial Drilling Products (IDP)…....…….…..........16

Better Water Industries, Inc.................................................18

Bit Brokers International.....................................................19

Bitco, Inc.............................................................................14

Bloom Mfg., Inc.....................................................................9

California Groundwater Association (CGA) Convention......43

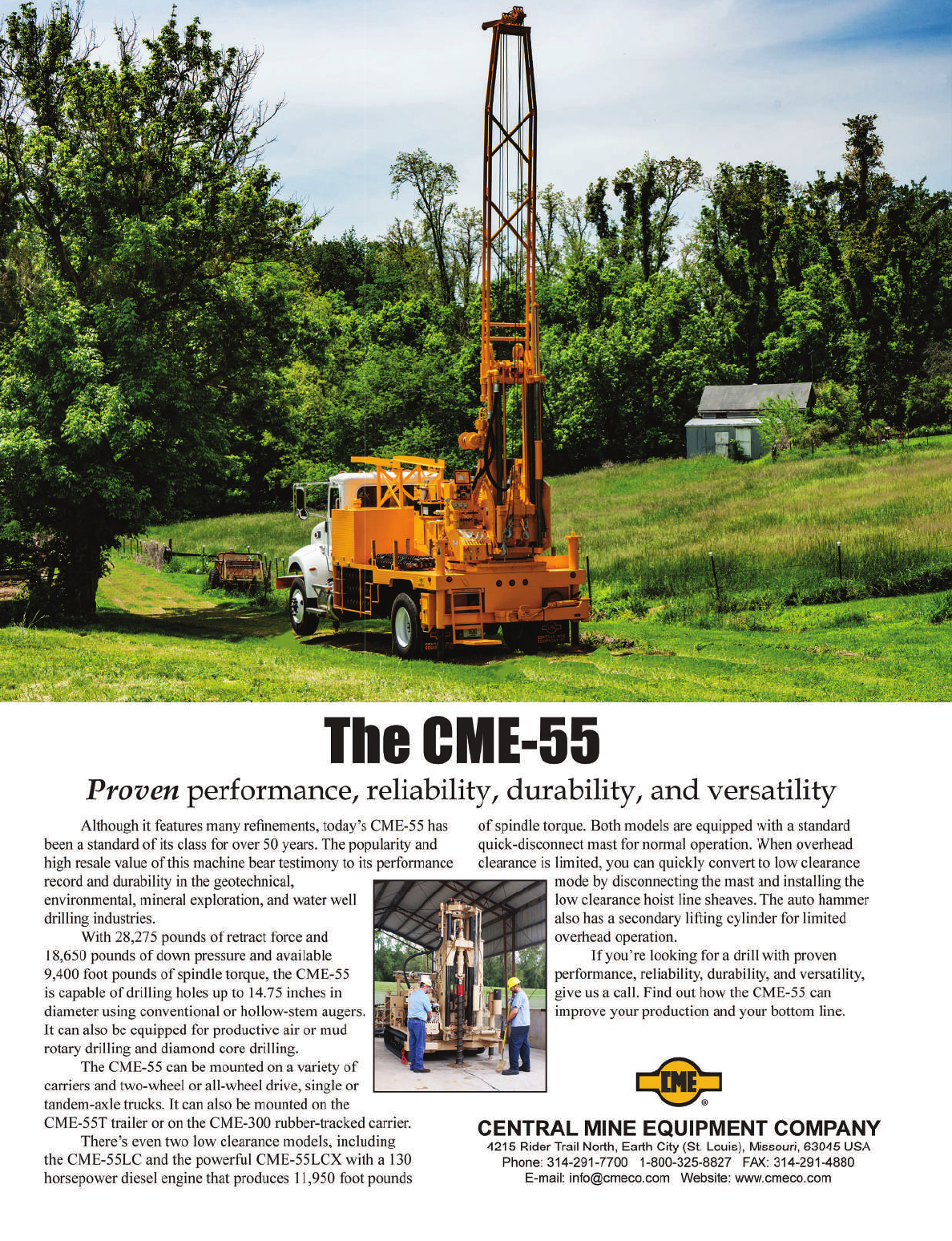

Central Mine Equipment Company (CME)..........................34

CONEXPO-CON/AGG

®

......................................................24

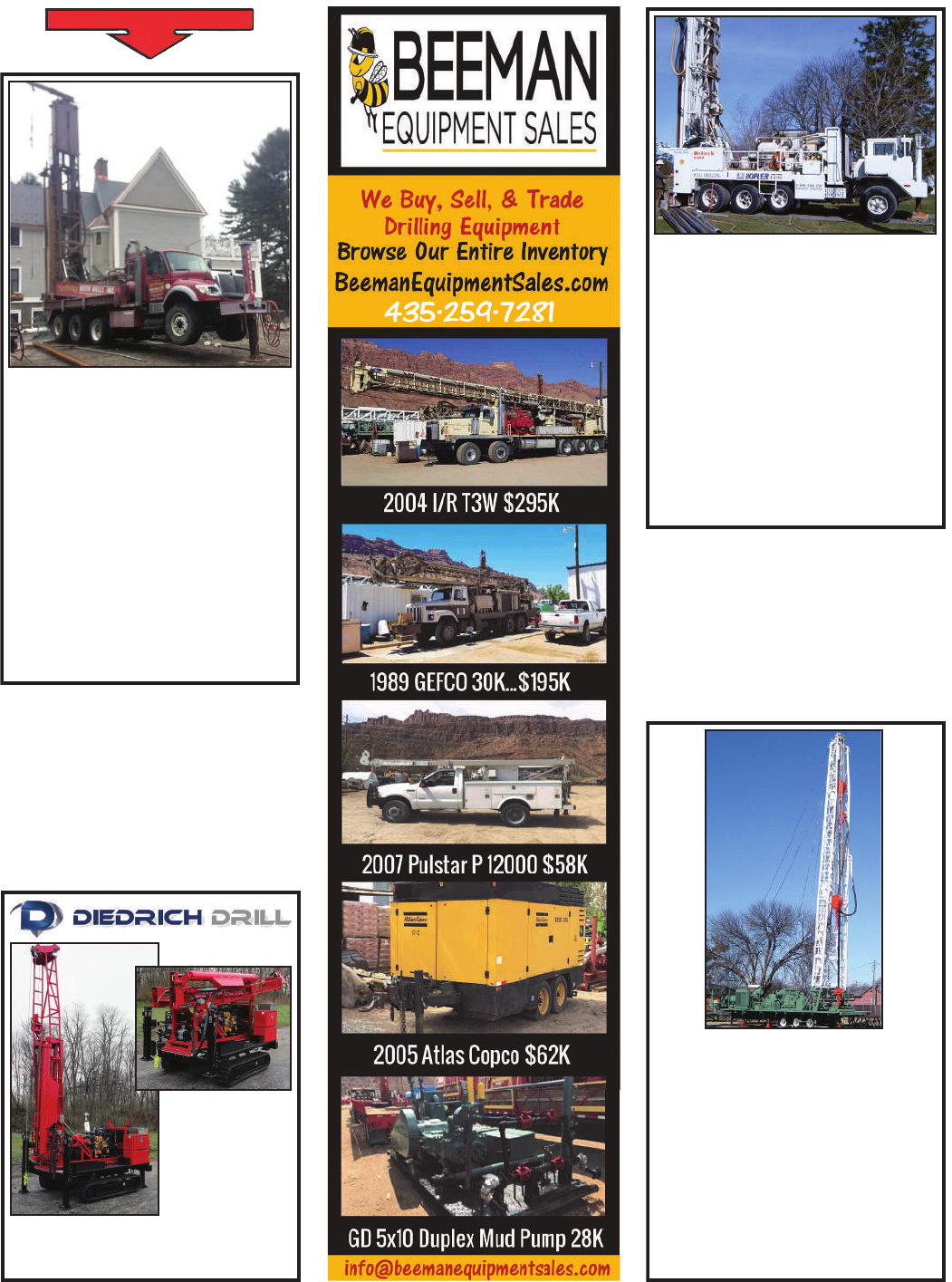

Diedrich Drill…....................................................................21

Drilling Equipment Sales, Inc. (DES)....................................1

Drilling Supply & Mfg (DSM)...............................................31

DRILLMAX

®

........................................................................64

Eastern Driller Manufacturing Company Inc. (EDM)...........62

Empire State Water Well Drillers Assoc. (ESWWDA) Ann. Mtg..17

Foremost Industries............................................................26

GEFCO, Inc. (an Astec Industries Company).......................2

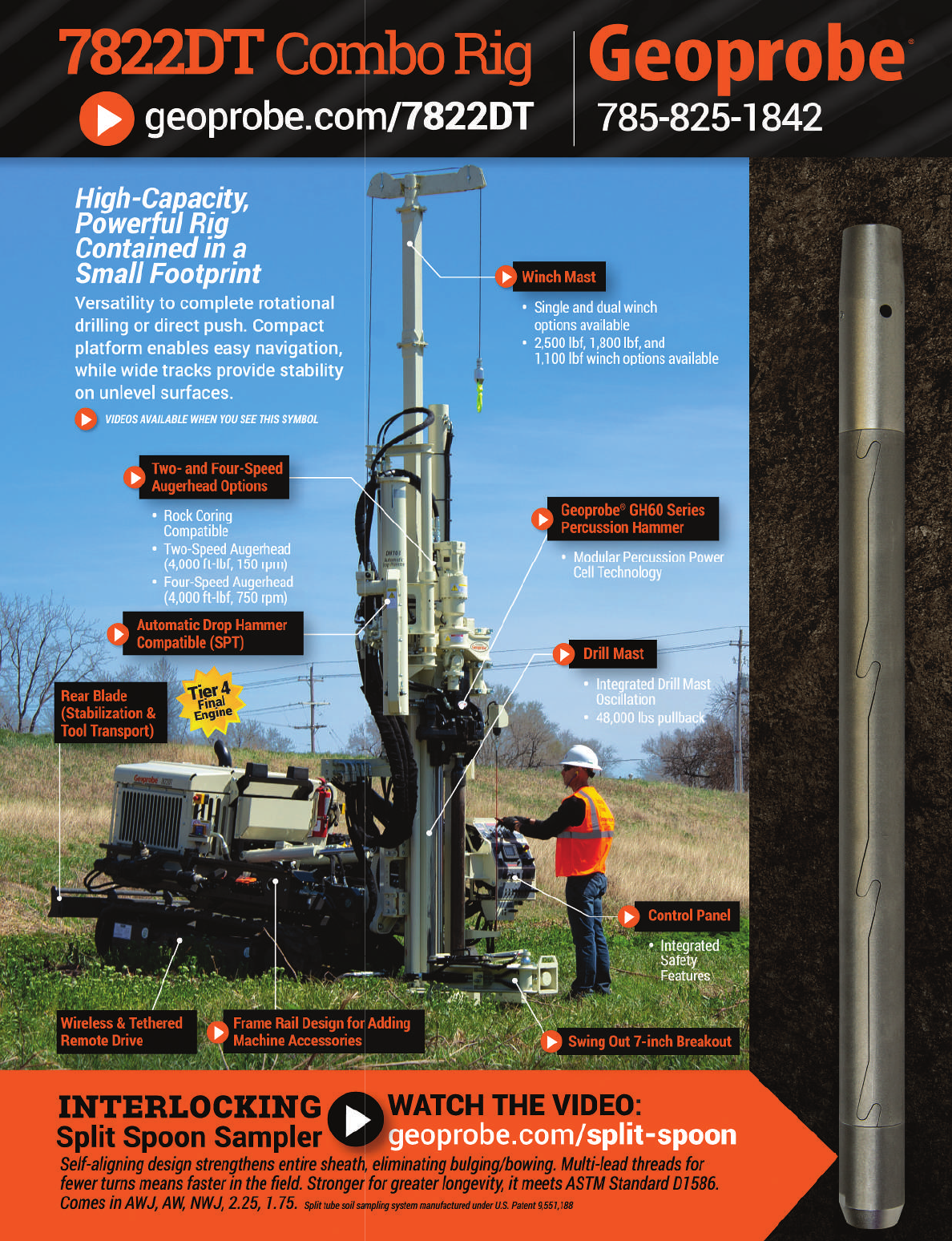

Geoprobe Systems

®

............................................................39

Geothermal Supply Company, Inc. (GSC)............................8

Grundfos Pumps Corporation.............................................15

Infinity Tool Manufacturing....................................................3

Kentucky Blasting Conference............................................20

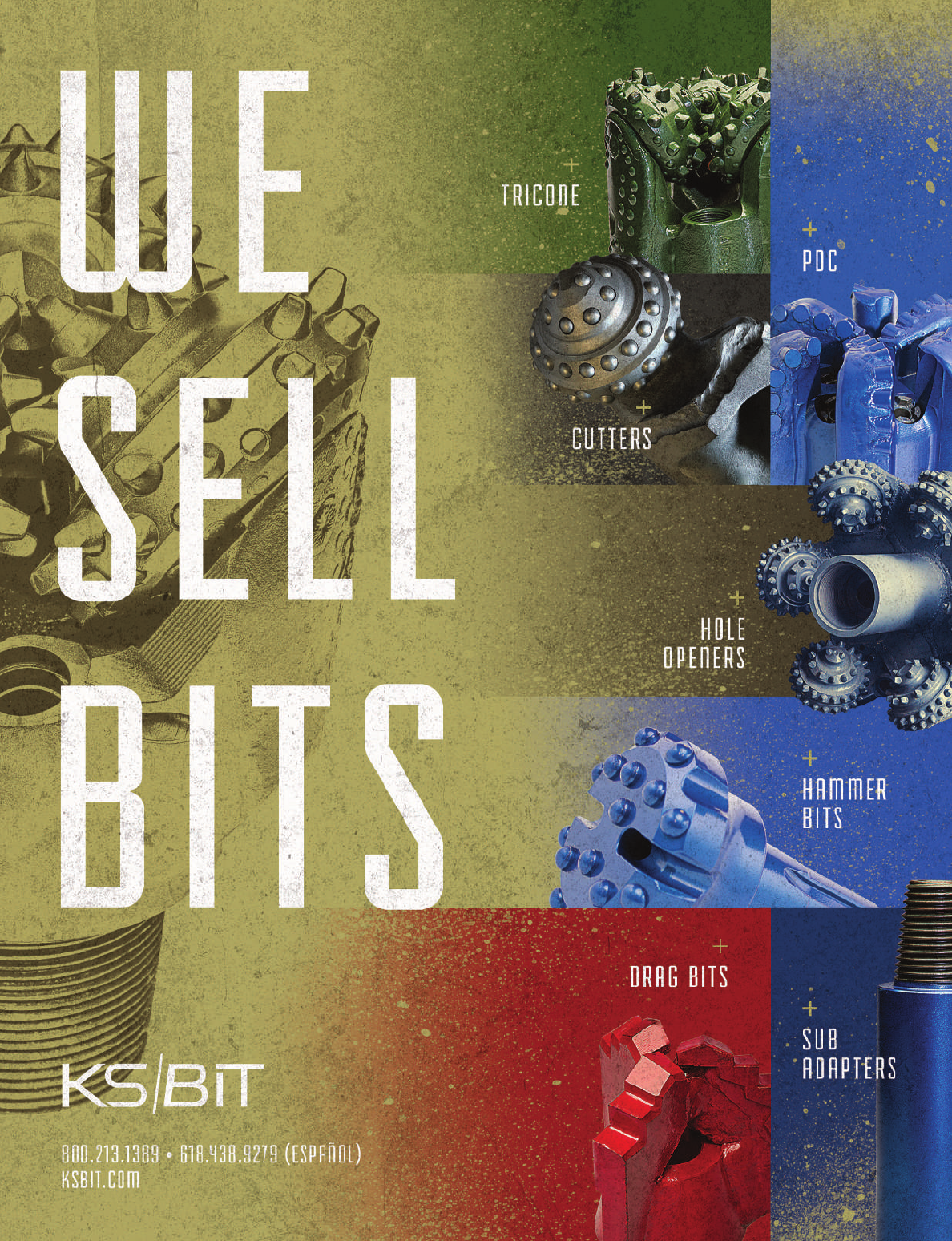

KS Bit, Inc...........................................................................49

Louisiana Ground Water Assoc. (LGWA) Convention.........30

Mills Machine Company, Inc...............................................29

N&N Drilling Supply.............................................................25

Palmer Bit Company...........................................................42

SEMCO, Inc........................................................................63

SIMCO

®

Drilling Equipment...................................................4

Star Iron Works, Inc............................................................22

Star Iron Works, Inc............................................................23

TDH Manufacturing Inc.......................................................40

Texas Ground Water Assoc. (TGWA) Convention...............37

Utah Ground Water Association (UGWA) Conf. and Expo..41

Well-Vu, Inc...........................................................................7

Wyo-Ben, Inc......................................................................13

Advertisers

Featured Editorial:

C&G - Construction/Geotechnical

ENV - Environmental

G&O - Shallow Gas and Oil

M

IN - Mining

DIR - Horizontal Directional Drilling

E

XB - Exploration/Blasthole

GEO - Geothermal

WTR - Water

Storkson, Britt: “New and Improved” Sometimes Isn’t..18

AEM - Leadership for Over a Century.......................28

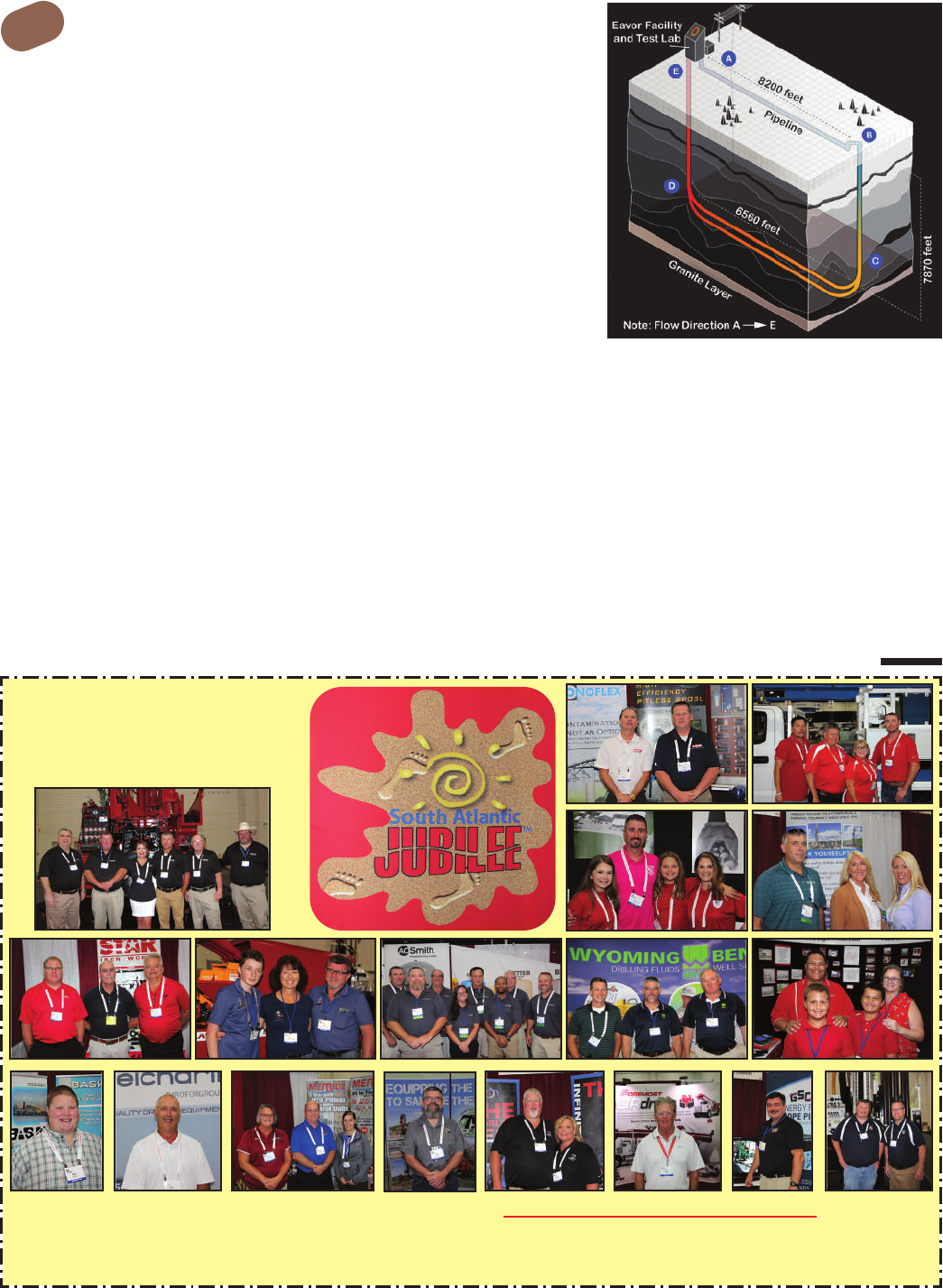

Canada Tests New Commercial-Scale Geothermal..38

Battersby, Mark E.: Drilling Into Money Not Boring..20

Keep the Airport Open...............................................36

“Smith, Billy Bob”: The “Idiot’s” Corner..................40

Curiosity, Mars Rover, Drills at Aberlady!..................14

Be Aware of Soil Contamination When Installing......25

Kwader, Thomas: Environmental Monitoring...........41

Wilson, Jr., Robert Evans: The Un-Comfort Zone II..........8

Canada Explores for Potential Rare Earth Elements....33

America’s First Gold Rush........................................43

White, Harold: Oil/Water Exploration.......................12

ExxonMobil - “Carrying the Brand”............................23

Former Gas & Oil Lab Open for Geothermal Testing...17

Ten Geothermal Projects Awarded Funding..............30

Wire, Jeremy: Tales from the Field..........................37

Clean, Cost-Effective, Reliable Energy Solution...........47

Copper: Bright Future - Glorious Past...........................22

E-News Flash

E-News Flash

Readers’ Choice

Readers’ Choice: Most Complete.......35

Joy Komatsu - A Century of Mining Solutions............44

Connor, Tim: Do It Now..............................................45

A Safer, Faster Way to Handle Casing Pipe................7

Ballard, Thomas: Notes from the Groundwater Guy..29

Kuebelbeck, Jim: Through the Back Door!..............32

Offering the Latest in Drilling Technology..................45

Rasmussen, Tim: Water For Life International........46

5

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

6

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

WorldWide

WorldWide

!

!

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The

c

ompl

e

t

e

magaz

ine

fo

r

th

e

dr

illin

g

in

dus

t

r

y

worl

dwide, owned by

drilling industry associates dedicated to bringing the most up-to-date

t

e

c

h

n

o

l

o

g

y

a

n

d

i

n

f

o

r

m

a

t

i

o

n

t

o

s

u

b

s

c

r

i

b

e

r

s

.

Co

v

e

r

i

n

g

const

r

uct

ion-

g

e

o

t

e

c

h

n

ic

a

l

,

d

ir

e

c

t

io

n

a

l

,

e

n

v

ir

o

n

me

n

t

a

l

,

e

x

p

lo

r

a

t

io

n

-

b

la

s

thole

,

shallow

ga

s

& oi

l

,

ge

ot

he

r

m

a

l

,

m

i

ni

ng

,

wa

t

e

r

we

ll

,

ir

r

ig

a

t

io

n

,

wa

s

t

e

wa

te

r

; fro

m b

its

, to

p

u

mp

s

, to

r

ig

s

, to

ta

n

k

s

, th

r

o

u

g

h

wir

e

,

a

n

d

m

o

r

e

-

wha

t

e

v

e

r

i

t

t

akes t

o get

t

he

dr

i

l

l

i

ng

j

ob

c

om

pl

e

t

e

d

!

M

a

na

gi

n

g

Publish

er/

C

EO/

Pre

side

nt:

Veronica I. “R

o

nn

i

e

” Jo

nes

Vice President:

Troy Cunningham

C

h

i

e

f

M

a

rke

t

i

n

g

Of

f

i

ce

r:

Ed

M

o

ra

n

ski

Of

f

i

ce

Ad

m

i

n

i

st

ra

t

o

r:

M

i

ch

e

l

e

St

e

ve

n

s

Ed

i

t

o

r:

Bo

n

n

i

e

L

o

ve

Ed

i

t

o

ri

a

l

C

o

n

t

ri

b

u

t

o

r:

C

a

ro

l

Sch

i

m

p

f

Public Relat

ions Prof

essionals:

Kat

hy Heinrich

Jan Allen

Production/Webmaster: Marcel Schimpf

Representative:

Marie Cunningham

Editorial Contributors for this month:

Tom Ballard Mark Battersby Tim Connor Jim Kuebelbeck

Thomas Kwader

Tim Rasmussen “Billy Bob Smith” Britt Storkson

Harold White Robert Evans Wilson, Jr. Jeremy Wire

Hyd/Eng Consultant:

Thomas Kwader, Ph.D.,P.G.

Consultant:

Mary Ann Pelletier

*

Editorial contributions & advertisements include statements of fact and opinions

that are the sole responsibility of the author and/or companies and do not

necessarily imply any opinion of the owners, management, or staff of

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

.

Images may have been altered for clarity.

Complete advertising information may be found at:

www.worldwidedrillingresource.com

or by calling 850-547-0102.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

makes every

effort

not

to place advertisements for “like” products on the same page in our

publication; this may occur however, due to size and space within the publication.

We regret any inconvenience this may cause our advertisers.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

i

s published monthly by:

WorldWide Drilling Resource, Inc.

, a Florida Corporation

PO Box 660 (

3089 Nor

thr

ide Lane)

Bonifay FL 32425-

0660.

Telephone: 850-

547-

0102 Fax: 850-

547-

0329

E-

mail: wwdr

@wor

ldwidedr

illingr

esour

ce.com

Website: www.wor

ldwidedr

illingr

esour

ce.com

Copyr

ight

2019,

WorldWide Dr

illing Resource, Inc.

Seen by countless

WorldWide

. Publication Agreement No. 40892520. Back issues may be

requested. Cost per issue $10.00 USD. No part of this publication may be

r

epr

oduced in any manner

without the str

ict wr

itten consent of the publisher

s.

Adver

tising

r

ates

fur

nished

upon

r

equest.

Editor

ial

contr

ibutions

ar

e

welcome

subject to editor

ial r

eview.*

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

reser

ves the

right to refuse any advertisement

.

We

We

Re

c

y

c

le

Re

c

y

c

le

After the Anniversary . . .

Time marches on and so do our relationships with our families, with our friends, and even with our work families.

We spend more time with our work families than with our real families at home - that is a fact based on eight plus hours

a day, or night for that matter.

So here is the question of the hour: “What would you do for your work family?”

Well, we could all think of a few things we would do like help them learn from us ~ the different, perhaps better or

quicker ways to complete a task whether it be at work or with something they need to do at home. We might even offer

to take them to the doctor, shopping, drop their children off at school, or even watch their children for them as they go

through some crisis of their own.

Now comes the BIG question . . .

Would you do anything in your power to ensure their future in your company?

What I mean by that is, would you put your future and that of your company on the line to find another avenue of

income the company could handle to ensure their futures and that of the company - even though there is some risk-

taking involved?

Well, if you started the company, you took risks, right? So the last question I have is this . . .

Do you think “Can’t Ever Did Anything?”

I, for one, don’t think it ever did and it never will - so some risk-taking for the sake

of your work family and their families as well as you and yours, is worth it. As my

husband and I used to always say, “We could start all over again in a tent, if everything

were taken away from us, and be happy.”

So march on we shall. Great things are on the horizon for you and

WWDR

~ stay tuned.

We Will See you on the trail!

NEXT STOP ~ CGA

With pen

(computer) in hand

. . .

Ronnie, Managing

Publisher

ronnie@worldwidedrillingresource.com

Canada

Constructs

Geothermal

Demonstration

Facility

Page 38

Featured Articles for October

Former Gas & Oil Lab Open

for Geothermal Testing

Page 17

Funding Awarded

to Geothermal

Projects

Page 30

A Reliable Energy

Solution for Australia

Page 47

7

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

A Safer, Faster Way to Handle Casing Pipe

A

dapted from Information by TekMark Industries, Inc.

Larry Williams was once an administrator and teacher at Eastern Washington University,

with his B.A. and M.B.A. in business. He acquired patents for casing elevators and casing slips

invented by Chester and Clyde Eastwood of Eastwood Drilling in Yakima,

Washington, and decided to open his own company, TekMark Industries, in 1975. The company’s first tools

were unique to the water well drilling industry and provided a safer, faster way of handling casing pipe installations

in open hole situations. The lifting system allows drilling operators to eliminate the need to weld lugs and the

use of cable slings to elevate and install casing.

Over the past 44 years, the company has flourished by providing innovative solutions to casing- and pipe-handling

problems and expanding its line with the addition of:

j Down-the-hole casing spears j Flush joint casing elevators j Torch cutoff guides

j Alignment clamps j PVC cutoff guides j Column pipe elevators

j Manual down-the-hole liner setters and casing retrievers

j A wide selection of drill pipe, core rod, and column pipe holders

The Tekmark Team works with thousands of customers worldwide, doing business with 8000 U.S. companies,

as well as customers in 71 foreign countries. One of those cus-

tomers is Dell Boyce. Here is what he had to say about his ex-

perience with the TekMark Team.

“I’m Dell Boyce. I own Boyce Drilling and we drill irrigation wells in the Columbia

Basin of Eastern Washington. I’ve been using TekMark Casing Lifters for about

six years. TekMark’s system is so much better than something you weld on and

then have to cut back off. I have the system for casing sizes from 6 inches through

18 inches. The speed and efficiency of the system saves us just about a full day

of casing setting time per well, and we just about pay for the tools on one job . .

. TekMark means safety and efficiency to me.”

With affordably priced solutions, the company is committed to continued cus-

tomer satisfaction and is looking forward to continued growth.

The TekMark Heavy

Lifter has a 140,000-

p

ound capacity.

Dell Boyce,

YouTube TekMark Casing.

WT

R

The Un-Comfort Zone II

by Robert Evans Wilson, Jr.

The Unfolding Gift of a Sister

I was sitting at the kitchen table eating my breakfast when I noticed, above me, a nail hole in the

plaster where a picture had hung. It was a black spot on the wall directly across from my sister, who was

sitting in a highchair busily eating her breakfast. I glanced over my shoulder toward the stove, and ob-

served my mother had left the room. It was my chance to have some fun. I knew my sister was terrified

of insects, so I called her name and emphatically pointed toward the hole in the wall, “Cindy, look, a bug!”

She screamed in horror, and I doubled over laughing. Mother rushed into the room to see what was the matter. After assuring

Cindy it was not a bug, she yelled at me for scaring her. I acted contrite, but inside I was still chuckling in satisfaction. I was

seven years old.

I had been an only child for four years, when my life as the center of attention in my parents’ world ended with the birth of

my sister. It’s tough for a four-year-old to share the limelight with a sibling when he never had to before. What I didn’t realize

was my parents were giving me a gift. She was a purposeful gift on their part, but I wouldn’t come to appreciate that for decades.

I don’t recall how often I teased, tormented, or bullied my sister, but it wasn’t enough for her to fear or dislike me, and for

that I’m grateful. By the time I was a teenager, our age and gender differences separated us emotionally, and I spent less and

less time interacting with her. I wasn’t intentionally ignoring her, I was just too caught up in my own life to be fully aware of

hers. This would continue until we were adults.

When we lost our dad to a stroke, I was there for her when she asked, but I was still too immature to recognize her needs

when she didn’t ask. Within a few years, we were both married, and only saw each other at the formal family gatherings at

Mother’s house on Thanksgiving, Christmas, and Easter. Then 11 years after Dad died, we lost Mother too. And, even though

Cindy was my last tie to the memories of our parents, we saw each other even less.

My parents’ great gift to me might have been lost had Cindy and I not been divorced by our spouses. It was when we both

went through our divorces that we truly discovered each other for the first time. We found the emotional strength we needed

to survive in each other. We talked on the phone frequently, and gave each other pep talks as needed. In the years since, we

have grown closer and closer.

Over the years I have come to love Cindy, not just as my sister, but as one of my best friends. Now, I can fully realize and

appreciate the value of the sacrifice my parents’ were making when they decided to have her.

You see, in 1960, my father was diagnosed with kidney failure. His doctors told him there was no cure, he was going to die, and

he and Mother needed to start making plans. The most remarkable plan they made was to

have another child. With my mother facing inevitable widowhood and single motherhood,

she agreed to have a second child. Their motivation was to save me from being an “only

child.” They decided to conceive a second baby, who might be born after Dad died, so

I would never be alone. As an adult, who has raised two children as a single parent,

I find it astounding they would have made such a decision. Yet, I am so happy they did.

You might recall from my previous article, Good Habit - Questionable Motive in the Nov.

2009

WWDR

WWDR, that my father, who was a builder, sold our house in preparation for his

death, and used the proceeds to build a three-unit apartment house my mother could rent

out and live in. I also wrote that my mother, who at the time was a stay-at-home mom,

was trained as an X-ray technician. She planned on going back to work part time once

my father passed away, then full time when Cindy and I were old enough for school.

In the meantime, she worked temporary jobs to keep her radiology skills up to date.

It was at one of those temp jobs she came across an article in a medical journal -

and it saved my father’s life. She read about a physician in Boston who was performing

the world’s first kidney transplants. At the time of publication, he was looking for volun-

teers who had to be an identical twin. My father was an identical twin, so my mother

called the physician, and he agreed to operate. My uncle agreed to give my father

a kidney, and my father became the 12th person in the world to have a kidney

transplant and live. He lived another 18 years - until Cindy and I were both adults.

Both of my parents died at relatively young ages. Losing them made me par-

ticularly grateful for their gift. At some of the most challenging moments of my life,

my sister has been there for me. I don’t know that I could have coped without her.

Thank you, Cindy. Thank you, Mom and Dad.

Robert

Robert is an innovation/change speaker, author, and consultant. He

works with companies that want to be more competitive through innovation

and with people who want to think more creatively.

For more information on Rob, visit www.RobWilsonSpeaker.com or contact

him via e-mail to michele@worldwidedrillingresource.com

Atlantis Vault

Atlantis Vault

• Self-Contained

• Self-Contained

• Simple installation

• Simple installation

• Trouble-free operation

• Trouble-free operation

For more information call:

(270) 786-3010

or visit us online:

www.geothermalsupply.com

8

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

CUSTOM SPECIALTY WINCHES FOR

WELL DRILLING AND PUMP HOIST TRUCKS

Manufactured with

your specifications

in mind

BLOOM MANUFACTURING, INC.

Custom Engineering Solutions Since 1910

Independence, IA 50644 USA

www.bloommfg.com

P: +1 319-827-1139

P: 800-394-1139

F: +1 319-827-1140

DESIGNED FOR OUTSTANDING

PERFORMANCE & SAFETY

MAINLINE WINCHES

3000 to 35,000 pounds

Up to 130 feet per minute

SANDLINE WINCHES

1800 to 8000 pounds

Up to 800 feet per minute

WINCHES

9

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

Numa Releases Range of HDD Drilling Systems

Numa’s HDD (horizontal directional drilling) systems consist of a variety of HDD components including hammers, bits,

side load sonde housings, bent subs, and adaptors capable of drilling holes 4 to 7-1/2 inches in diameter, and are designed

for productive and efficient drilling in hard rock and fractured ground formations. Some of the many benefits of Numa’s HDD

hammer line are improved steerability, fast penetration rate, simplified field maintenance, reduced air requirements, and

lower overall cost per foot.

“Numa has a long history of serving the HDD market, and with our range of HDD Drilling

Systems, we enhance our ability to serve our customers with the right products for the

job,” said Numa President Ralph Leonard. “Our high-quality, Made in the USA HDD prod-

ucts provide the right balance of performance and dependability without

sacrificing tool life.”

A single bore design allows for a maximum bore diameter, along with

providing optimum life against abrasion.

Numa’s full line of HDD Drilling Systems includes the models:

j

HDD 35 for holes 3-7/8 to 4 inches in diameter

j

HDD 40 for holes 4-3/4 to 5 inches in diameter

j

HDD 50 for holes 5-3/4 to 6-1/8 inches in diameter

j

HDD 60 for holes 7 to 7-1/2 inches in diameter

For a link to this website, visit worldwidedrillingresource.com

&DUROLQH6WUHHW

3XQ[VXWDZQH\3$

:HE6LWHKWWSZZZVWDULURQZRUNVFRP

(PDLOVDOHV#VWDULURQZRUNVFRP

)$;

To be noticed,

give us a call: (850) 547-0102

or e-mail: wwdr@

worldwidedrillingresource.com

ZZZURFNPRUHLQWOFRP

12 OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Oil/Water Exploration

by Harold White

When I write an article in

WWDR

WWDR, a lot of well-educated people are reading it, so I have had a few

calls and questions from them. The last letter I received from a New York subscriber, wanting to know

what I use to detect water, gas, and oil, and why I haven’t written about the equipment I use. I have

written about the equipment I use. I can do everything I say I can, and all the stories in

WWDR

WWDR are

about things I have done.

I have a been a well drilling professional since 1952, locating underground fluids for domestic,

stock, irrigation, city water wells, oil wells, gas wells, hot water wells, and pumps.

I have written about my friend Jereal in Kentucky, who has an advanced radiometrics type of detection for these fluids he

built years ago, and has been improving it ever since. We worked together doing detection, finding gas and oil. I taught him to

sense the underground fluids.

In another article, I wrote about Cecil, a friend from Texas who operates a radiometrics detection device. He asked me to

take him flying in a rental Cessna 150 airplane. The company would pay to fly over some areas in Kentucky with his radio, and

map the area for gas and oil. I could see way ahead of his detection - I could tell him where and when his detection unit would

find gas and oil fractures. What did I use for detection? My vision, my friend, his radiometric unit, and an airplane. Yes, this all

worked.

I was the pilot. My father learned to fly from Charles Lindbergh before Lindbergh flew across the ocean, and I learned to

fly from my father, Albert White.

Harold

Harold White may be contacted via e-mail to michele@worldwidedrillingresource.com

G&O

Vermeer Location Expands

Vermeer Mid Atlantic, an All Roads company, has acquired Vermeer Northeast, a

Pinnacle Award-winning dealer partner of Vermeer Corporation. The combined com-

panies will adopt a new brand name - Vermeer All Roads.

Vermeer All Roads will have 15 locations covering South Carolina, North Carolina,

Virginia, Maryland, Delaware, Pennsylvania, West Virginia, Ohio, New York, Maine,

Connecticut, Rhode Island, Massachusetts, New Hampshire, and Vermont.

“Vermeer Mid Atlantic’s demonstrated market leadership is greatly enhanced by the

addition of Vermeer Northeast,” said Mark Boyle, president of Vermeer Mid Atlantic.

“We look forward to delivering exceptional service and building on the success the

Vermeer Northeast team has established in the market over the last 50+ years.”

Breaking News

Breaking News

WHO’S IN THE NEWS

WHO’S IN THE NEWS

You can find additional announcements from Sandvik and Messe München

Shanghai in our online issue at: worldwidedrillingresource.com

Send your Who’s in the News to:

Bonnie@

worldwidedrillingresource.com

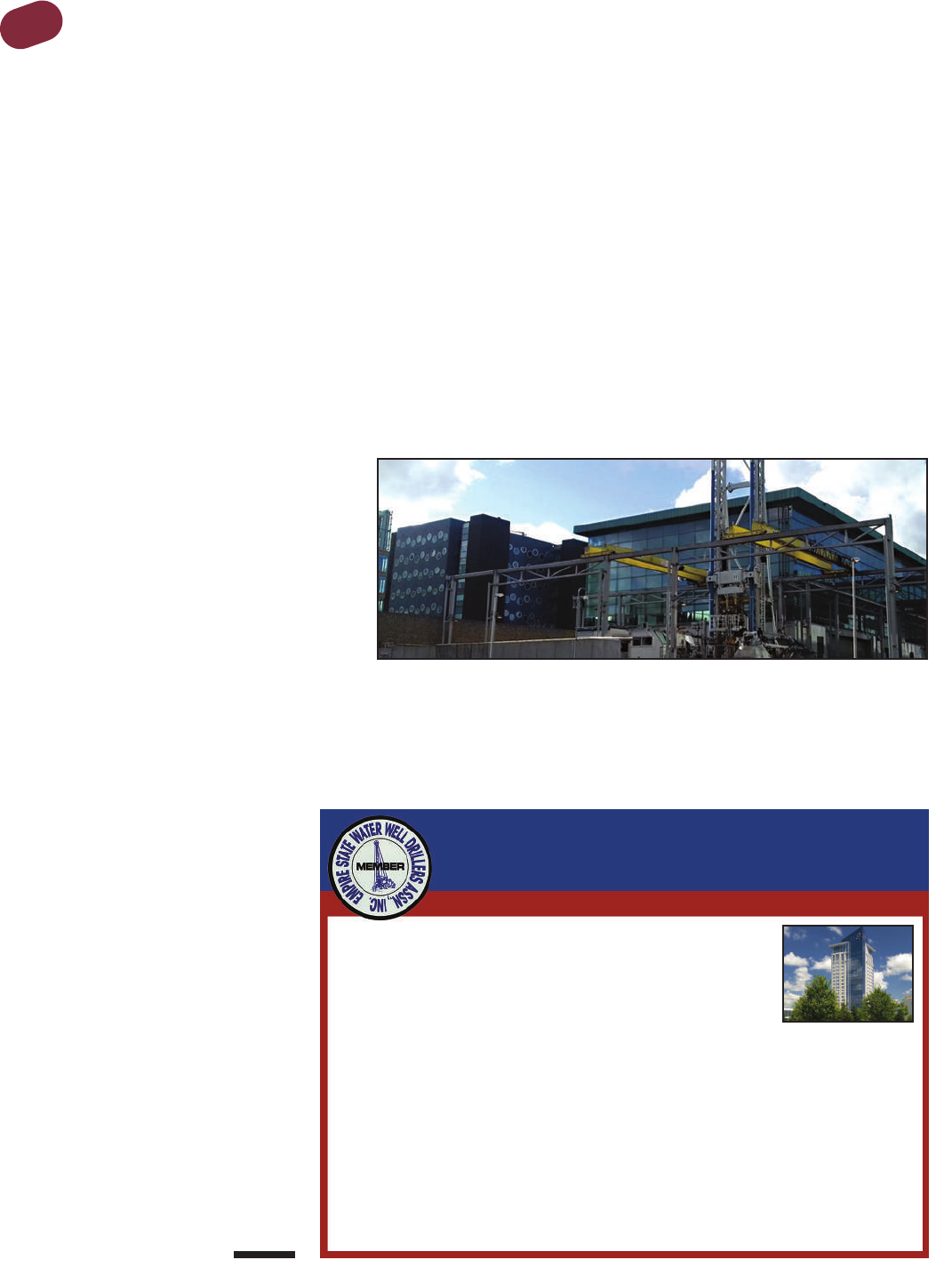

Astec Industries Appoints New CEO and President

Astec Industries, Inc. announced the appointment

of Mr. Barry Ruffalo as president and chief executive

officer. He has also been elected to the Board of

Directors as a Class I director and will stand for reelection

at the Company’s 2020 annual meeting.

“After a comprehensive search that included a

number of highly qualified candidates, we are excited

to hire Mr. Ruffalo,” said Bill Gehl, chairman of Astec.

“Barry brings a wealth of experience to Astec. He is

a leader that has driven change, understands infra-

structure, and will add tremendous value.”

Two Rivers Marketing

Jean Hiller of Two Rivers

Marketing has retired. She is look-

ing forward to travelling with her

husband as she joins the ranks of

several industry colleagues and

friends who have retired.

“I have loved my work in this

industry over the past 38 years, and

it has been a great honor and pleas-

ure . . . There are many talented

individuals who drive the industry,

working for manufacturers, media,

associations, and marketing agen-

cies, and I will miss my interaction

with all of them,” she stated.

13

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

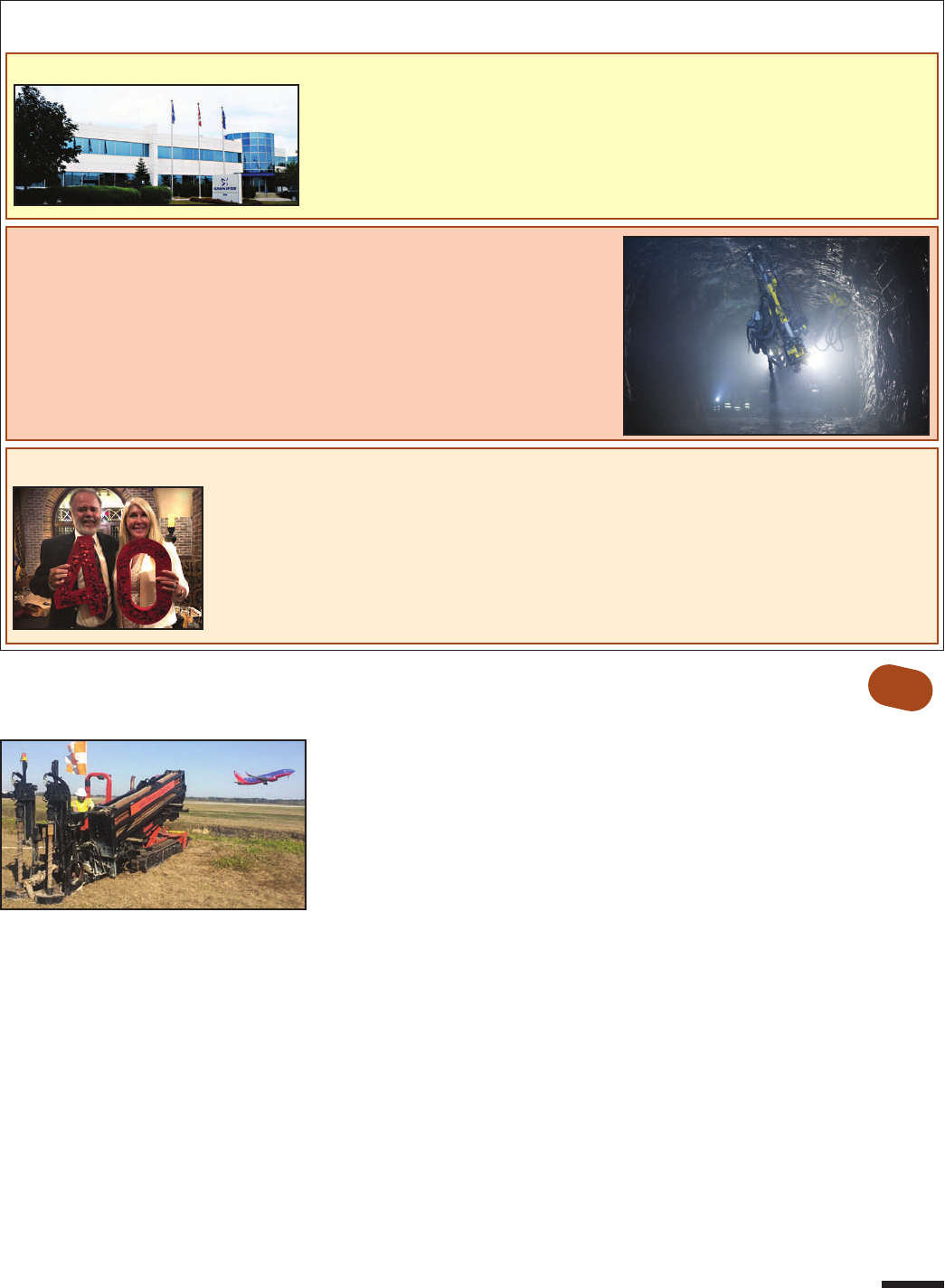

Curiosity,

Mars Rover,

Drills at Aberlady!

Adapted from Information by

The American Geophysical Union

and The National Aeronautics and

Space Administration

Scientists working with Curiosity,

the Mars rover, have been excited to

explore a region called "the clay-bearing

unit" sin ce bef ore the spacecraft

launched. The rover finally tasted its first

sample from this part of Mount Sharp

when it drilled a piece of bedrock nick-

named "Aberlady". The rover's drill

chewed easily through the rock, which

was so soft, the drill didn't need to use its percussive technique. This was the mission's first sample obtained using only rotation

of the drill bit.

The Aberlady sample will give the team a starting point for thinking about the clay-bearing unit. Over the course of a year,

several more drilling operations are planned, which will help the team understand what makes this region different from the

ridge behind it, and an area located higher on the mountain with a sulfate signal.

The team recently analyzed two targets with ChemCam (chemistry and camera) - the inside of the drill hole (Aberlady)

and a nearby bedrock target Mayar. They had to determine if a powdered rock sample had been collected, and whether it

was behaving as expected. Small portions of the sample were dropped onto the workspace on the SAM (sample analysis at

Mars) inlet cover. Using Mastcam (mast camera), they took images before and after these drop-offs, which helped them char-

acterize their ability to deliver portions of the sample to the rover’s laboratories.

A few interesting observations were made - the drilled block lifted up slightly as the drill was retracted, there might be some

evidence of a horizontal calcium sulfate

(gypsum) vein within the drill hole, the drill

went into the rock easily, and the drill tailings

appeared to clump more than usual. Some

concern was expressed by instrument

engineers and scientists about whether

this outcrop may have penetrated into a

weak underlying layer, preventing enough

of the sample from making its way up into

the drill stem for later drop off to CheMin

(chemistry and mineralogy) and SAM.

The rover used a sample portion for

the CheMin analysis to get a better under-

standing of the material. Initial results looked great, meaning CheMin received

enough sample, and the team did not need to deliver more material. So, the team

dumped the rest of the sample on the ground where they could analyze it with

Curiosity’s remote sensing instruments. The team collected APXS (alpha particle x-

ray spectrometer) of the dump pile with two offset observations to better under-

stand any compositional variations. They also performed another CheMin integration

to further refine the mineralogical analyses for Aberlady.

With time at Aberlady coming to a close, the team focused on refining their

understanding of the composition of local rocks and drilled material. ChemCam

took measurements of the drill hole, and accompanying MAHLI (Mars hand lens

imager) images will be used to characterize a potential vein within the drilled rock.

ChemCam also targeted the edge of a large bedrock chunk, which appeared to be

uplifted during drilling.

The search for the next drill target has already started. The team discussed two

different options which are near the current workspace. These targets were

weighed against the option to head back toward a site they already passed or to

do a small walkabout to scout out other promising bedrock outcrops. While the next

drill target may only be a few feet away, the team is looking forward to wrapping up

activities at Aberlady and moving on to their next workspace.

Courtesy of the American Geophysical Union.

New & Used Bits,

HDD Bits & Tools,

Drag Bits & Wings,

Bolt-On Drag Bits,

Reverse Circulation

Tools, Hole Openers,

Claw Bits, Stabilizers, Subs,

Custom Tooling & Welding,

Hammer Bits, Drill Collars,

Pipe Wipers, and Drill Pipe.

Office: (661) 834-4348

Rod Henderson / Eran Henderson

661-201-6259 • 661-330-0790

sales@bitcobits.com

www.bitcoinc.us

14

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The SQ submersible pump from Grundfos Pump Corporation is

extremely compact and ideal for small or restricted boreholes. At

j

ust 2.9 inches in diameter and weighing 14.8 pounds, it fits all

wells three inches or larger. It offers a number of motor protection

and wear-reducing features which make it a good choice for res-

idential wells, irrigation systems, or groundwater lowering. The SQ

pump is suitable for both continuous and intermittent operation

for a variety of applications and can be installed vertically or hor-

izontally. Low current draw and soft start allows use of smaller

gauge wire compared to traditional

four-inch motors, which can reduce

the overall cost of installation.

Grundfos Pump Corporation is a Valued

WWDR

WWDR Advertiser.

E

N

V

Former Gas and Oil Lab Open for Geothermal Testing

A

dapted from Information by TNO

TNO, the Netherlands Organisation for applied scientific research, announced companies active in geothermal energy

now have access to an advanced state-of-the-art laboratory in Rijswijk, South Holland. The Open Innovation Centre for Well

Technology (OIC-WT) can be used for full-scale testing and experimentation with new drilling techniques and materials under

high pressure and extreme temperatures.

The former Shell technology laboratory has been transformed into a geothermal technology innovation lab, in collaboration

with a consortium of partners including TNO, TU Delft, Utrecht University, EBN (Energie Beheer Nederland B.V.), Ministry of Economic

Affairs, the province of South Holland, the Ministry of the Interior and Kingdom Relations, and the municipality of Rijswijk.

“As a drilling company, we have a lot of R&D [research and development] knowledge and installations in-house, but the equip-

ment in this lab is unprecedented,” said Peter de Vin, director of Huisman Geo. “And that, combined with the in-depth knowledge

of two universities and TNO, makes this facility an innovation center where Dutch industry can take major steps to make geother-

mal energy a success. As far as we are concerned, things are still going too slowly. This enables us to move things up a gear.”

According to Gert-Jan Heerens of TNO, geothermal energy plays an important role in the energy transition; it is one of

the most important sources of renewable energy supplies. Geothermal energy could potentially supply about a quarter of the

country's total demand for heat. However, there is still much to be done in terms of more efficient and cost-effective drilling,

with an increasing focus on safety. In short, many technical innovations are needed. These can be developed and tested

under the most extreme conditions of high pressure and temperature, at the facility.

The consortium decided to open the facilities to any company interested in working on new methods and products. “This

will bring about ideas. Like the universities, at TNO we can make the connection between scientific knowledge and its appli-

cation in practice. In this way, together we can achieve much more at a much faster pace. Who knows, maybe we'll develop

methods or equipment here that will soon spread

worldwide,” stated Heerens.

The facilities are impressive. There is a huge

drilling installation, including a full-size rig, above

a well nearly 1640 feet deep which can be used

to test new materials and methods. The center

also has overhead cranes, hydraulic presses,

pressure vessels, piping systems for pumping

and testing liquids, multiple flow loops, and two

drill holes. Almost all underground conditions can

be realistically simulated to determine how ma-

terials and components will behave under high temperatures belowground.

The beauty of the open innovation model is companies do not have to invest in test facilities themselves. “That's just too

expensive and that's why potentially wonderful findings remain unused. Even for a well-equipped company like Huisman, this

lab is a technological land of milk and honey in this field. Not only do we want to test materials, but we are also interested in

the data that comes out of it. I am thinking, for example, of collaborating with companies that specialize in sensor technology.

By integrating sensors into the drilling process, you can drill much smarter and accurately predict when maintenance is needed.

In this way, you can reduce the costs over

the entire life span. Here in the lab, you

also meet entrepreneurs from other sec-

tors. I can see surprising combinations

happening and therefore innovations,”

explained de Vin.

The cooperation is not limited to

industry, universities and polytechnic

institutions are also welcome in the OIC-

WT. “We'll have to build about 700 geo-

thermal doublets in the long run. Now

there are less than 25 of them. And once

built, they need maintenance. But there

is no training for that in our country.

Companies that build wells are now

mainly focused on oil and gas produc-

tion. Here, students can get to know the

world of geothermal energy, conduct

research, and carry out experiments that

are impossible elsewhere. This should

also lead to acceleration,” said Heerens.

Empire State Water Well Drillers

Association Annual Meeting

January 14-15, 2020

For more information, visit us online:

www.nywelldriller.org

January 14

th

9 am - 4:30 pm Board Meeting, Variety of Classes (TBD)

4:30 - 7:30 pm Cocktail Party & Trade Show

January 15

th

9 am - noon General Membership Meeting

Turning Stone Resort Casino

Verona, NY

For Hotel Reservations: 800-771-7711

www.turningstone.com

17

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

G

E

O

“New and Improved” Sometimes Isn’t

b

y Britt Storkson

Owner, P2FlowLLC

I have an old Briggs & Stratton eight-horsepower engine. It’s a dated flathead design I use to run an

electric generator. It’s not very pretty, but it has a lot going for it: It works, and it works reliably. It starts

every time, in any weather, cold or hot. It’s really simple and does the job using very few parts. Granted,

it’s not super fuel efficient (good, but not great) and it’s fairly noisy, but overall, it works well. Why should

I change?

When new technology comes out, often the “titans of industry” get so wrapped up in the “new technology hype” they often

neglect to fully test the “new toy”. It has been reported that Boeing aircraft switched to new-technology lithium-ion batteries to

save weight in their 787 aircraft. Lithium-ion technology can store more energy pound for pound over the older lead-acid battery

technology it replaced. However, the lithium-ion technology presented problems the old style batteries didn’t - like overheating

under certain conditions.

By the time Boeing made the modifications needed to utilize the lithium-ion technology safely, whatever advantage the

new battery technology afforded was wiped out by the changes that had to be made to make the new technology safe and re-

liable. While I am not aware of Boeing reporting any numbers regarding this issue, I think it is safe to say the new technology

cost the company considerably more than the conventional components - but that should have been determined long before

it was released for sale to the public.

We need to utilize the strengths and mitigate the shortcomings of both computer and human operators. We should take

advantage of what computers are really good at, as well as what humans are really good at. Computers never get fatigued or

distracted. Computers have a great memory - they don’t forget things. Humans are superior in other areas, as well. Humans

can make “judgement calls” - making the right decision most of the time without explicit instructions.

When I’m making printed circuit boards, I carefully evaluate what does and does not need to be on the board to make

everything work. It’s easy to use five or more components when one would do the job. While often done in industry, “piling on”

is not a good practice in electronics. More is almost never better. For one thing, printed circuit board space is expensive and

“piling on” is a bad practice from the cost aspect alone. Additional components sometimes generate heat, which may require

a way to remove this heat, such as a fan. Then you need some sort of sensor to shut everything off in case the fan fails . . .

and on and on.

Without adequate evaluation and discipline, you get this domino effect where one addition often triggers three or four other

changes. When the circuit has more components, it gets more costly, which is a good reason in and of itself to keep things

simple. More components require more

testing - and the potential for more to go

wrong. In fact, most of the advances in

electronics over the last 20 years or so

haven’t changed the basic building

blocks t o a n y s i gn i f i ca n t d e g re e .

Microprocessor manufacturers have

been busy consolidating several func-

tions on one “chip” mostly to reduce the

costs of making them. So while the “new

and improved” part may cost roughly the

same, the additional features for the

same price give them a “leg up” on the

competition.

So remember “new and improved”

isn’t always the best way to go.

Britt

Britt Storkson may be contacted

via e-mail to michele@

worldwidedrillingresource.com

18

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

December Issue Deadlines!

Space Reservation:

October 25

th

Display & Classified

Ad Copy:

November 1

st

Pipe

by: American Society of Civil Engineers

Design and Installation

o

f Buried Pipes

November 14-15 ~ Portland, OR

phone: 703-295-6300

www.asce.org

Pumps

by: Franklin Electric

Residential Basic

N

ovember 12-13 ~ Wilburton, OK

phone: 800-348-2420

www.franklinwater.com/more/

training/franklintech-schedule/

19

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

Blasting

by: Sandvik Mining and Rock

Technology / Dyno Nobel

Quarry Academy

®

November 19-21 ~ San Antonio, TX

www.quarryacademy.com

Construction

by: Concrete Sawing & Drilling Assn

Operator Certification

November 11-15 ~ Clearwater, FL

phone: 727-577-5004

www.csda.org

Foundations

by: Pile Dynamics, Inc.

State of Practice: Quality Control &

Quality Assurance of

Deep Foundations Workshop

November 11 ~ Miami, FL

November 13 ~ Tallahassee, FL

November 15 ~ New Orleans, LA

phone: 216-831-6131

www.pile.com

Groundwater / Water Well

by: Princeton Groundwater, Inc.

Remediation Course

November 4-8 ~ Tampa, FL

phone: 813-964-0800

www.princeton-groundwater.com

by: Washington State Ground Water

Association

Driller & Pump Installer Seminar

November 9 ~ Spokane, WA

November 15 ~ Tacoma, WA

November 16 ~ Kelso, WA

phone: 360-757-1551

www.wsgwa.org

Irrigation

by: Rain Bird Academy

Training

November 4-8 ~ Redmond, OR

November 4-8 ~ Denver, CO

November 5-7 ~ Santa Fe, NM

November 11-15 ~ Irwindale, CA

November 11-15 ~ Durham, NC

November 12-14 ~ Eatontown, NJ

November 18-22 ~ Fort Myers, FL

November 18-22 ~ Boston, MA

phone: 800-498-1942

www.rainbirdservices.com

Education

Education

Connection

Connection

Ms. Bonnie,

Good morning. May I please say

thank you so very much . . . It is for

certain a total joy for us to be

included in your publication like

t

his, thank you again! I hope you all

have a wonderful day.

Cheerfully in Christ,

Laura Maurizzi

Marketing Coordinator

Baker Manufacturing Company,

LLC

Evansville, WI

Drilling Into Money Not Boring

by Mark E. Battersby

HSAs: Tax Savings and Inexpensive Worker Benefit

Since they were created in 2004, tax-advantaged Health Savings Accounts, or HSAs, have grown

into a successful multifaceted tool for employers, as well as small business owners seeking self-only

health-care plans.

Used in combination with a high-deductible health plan (HDHP), HSAs have proven to be a free-

market option that does not rely on mandates or cash subsidies. Best of all, HSAs provide a health insurance

option for the self-employed or small business owner reluctant, or unable, to afford health-care coverage other than for themselves.

The concept of HSAs is both simple and elegant: Give individuals generous tax breaks to put aside money to help pay for

their health care. This, in turn, would make it easier for employers to offer their employees affordable high-deductible health

plans. For 2019, the Internal Revenue Service defined a HDHP as any plan with a deductible of at least $1350 for an individual

or $2700 for a family.

Much like an IRA (Individual Retirement Account), HSAs benefit from three tax breaks. Both contributions and investment

income earned on the accounts are tax-free. Withdrawals are also tax-free as long as they are used for qualified health-related

expenses. After age 65, participants may withdraw funds for any purpose, although the withdrawals are treated as ordinary in-

come for tax purposes.

Funds in an HSA can, as mentioned, be used to pay deductibles and other qualified health-related expenses including

dental, vision, or other health services not covered by insurance. Money remaining in the HSA can be invested, growing year-

after-year, even if workers change jobs.

HSA participants or “owners” saw a $50 increase in the 2019 HSA contribution level to $3550 for individuals with self-only

coverage. For those with family coverage, the annual contribution level is up by $100 to $7000.

An option which should not be ignored is the small business health care tax credit (SBHCTC). The SBHCTC is available to

employers with fewer than 25 employ-

ees, pay annual wages of less than

$50,000, and that contribute a uniform

percentage of at least 50% of the premi-

um cost for employee health insurance

coverage obtained through a Small

Business Health Options Program

(SHOP) Exchange. The maximum tax

credit has been extended through 2019,

and is generally 50% of employer-paid

premiums. It can be taken for only two

years, which must be consecutive.

Advice from a tax professional

and/or plan administrator, usually a

bank, financial institution, or insurance

company, is obviously a necessity.

Mark

Mark E. Battersby may be contacted

via e-mail to michele@

worldwidedrillingresource.com

46

46

th

th

Annual

Annual

Kentucky

Kentucky

Blasting

Blasting

Conference

Conference

December 5-6

Lexington, KY

Lexington Center /

Hyatt Regency Hotel

Conference includes 2 sessions of technical presentations,

and 4 workshop sessions which can provide up to 12 hours

of continuing education for licensed blasters in Kentucky.

REVIEW the basics of blasting methods and materials.

VISIT over 50 exhibit booths and see the latest products and equipment

available.

LEARN the latest techniques and evaluate the results.

EARN continuing education hours for renewal of your blaster’s license

or certificate.

For more information send an e-mail to: kbconf@yahoo.com

or visit our website: kyblastingconference.com

20

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

In Memoriam

Rick L. Thomas (1952~2019)

The

WWDR

WWDR Team was saddened to hear of the passing of Rick L. Thomas on August 13, 2019. He

and his wife Nancy have owned and operated T&T Carbide, Inc. in Logan, Illinois, since 1976.

Rick and Nancy were married 48 years. He loved working outside, playing with his grandkids and

grandbabies. He will be dearly missed as a loving husband, father, grandfather, brother, and friend to many.

Rick is survived by Nancy; daughter Audra; son Adam (Jane); grandchildren Kailey (Dave), Mikah

(Asa), Shay, Addyson, Remington, Lincoln, Sawyer, Ellie, Matilda, and Witten; great-grandchildren Lil Dave, Keegan, Zaedyn,

Roxzyn, Lynlee, Titus, and Kipling; brothers Garry (Sharon), Tim (Annette), and Alan (Beth); numerous nieces, nephews, and

extended family.

Lest we forget...

800-348-8809

219-326-7788

LaPorte, Indiana 46350

wwwwww..ddiieeddrriicchhddrriillll..ccoomm wwwwww..ttwwiitttteerr..ccoomm//DDiieeddrriicchhDDrriillll

wwwwww..ffaacceebbooookk..ccoomm//DDiieeddrriicchhDDrriillll//

CC

aa

ll

ll

FF

oo

rr

AA

vv

aa

ii

ll

aa

bb

ll

ee

SS

tt

oo

cc

kk

D

o

n

’

t

f

o

r

g

e

t

t

h

e

t

o

o

l

i

n

g

!

CUSTOMIZE

CUSTOMIZE

IT YOUR WAY

IT YOUR WAY

Your Options

Your Color

We will do our best

to accommodate

your needs…

21

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

www.starironworks.com

257 Caroline Street

Punxsutawney, PA 15767

800-927-0560 • 814-427-2555

Fax: 814-427-5164

SERVING THE WATER WELL INDUSTRY

Serving the Drilling Industry

22

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Copper: Bright Future - Glorious Past

Adapted from Copper Development Association, Inc.

First used by man over 10,000 years ago, copper was, for

nearly five millenia, the only known metal, thus having all the metal

applications. Initially decorative and then utilitarian, copper was, around 300 B.C.,

alloyed first with arsenic and then with tin. When the Bronze Age suddenly ended at about 1200

B.C., the interruption of international trade routes forced economy in the use of copper. From

then to now, efficiency in copper use and reuse has continued.

L

arge-scale mining of copper began in the late 1800s, primarily in the American West.

Open-pit mining techniques were developed, and the U.S. quickly became the world’s

largest copper producer. In 1877, Thomas Doolittle, a Connecticut brass mill man, devel-

oped hard-drawn copper wire strong enough to be strung overhead. When the telephone

system was commercialized, both it and the electric power grid began to con-

sume large quantities of copper wire. Similar developments occurred in the rest

of the industrialized world. From the early 1890s to the mid-1970s, annual world

consumption grew by about a factor of 30.

The U.S. copper industry consists of two main segments, producers and

fabricators. Producers’ products are sold mostly to fabricators, while fabricators’

products are sold to the construction industry, manufacturing industry, and the govern-

ment.

U.S. copper and copper alloy industry structure has undergone dramatic

changes over the last 10 to 20 years. Whereas the U.S. was the largest producer

and consumer of newly-mined copper, now Chile has taken the lead. The U.S.

share of world mine production is now about 18%, while Chile’s share is 23%.

Today, as copper maintains its markets, this must be balanced against its

future availability. Of the world’s reserves, about one-quarter of the deposits are economically recoverable now or in the near

future. Each year about three billion pounds are withdrawn from the earth as U.S. mine production.Three key factors will influ-

ence copper supply in the future: U.S. self-sufficiency, energy efficiency, and recycling efficiency. But more copper is recovered

and put back into use from recycled material than is derived from mined ore, so copper will most likely continue its 10,000-

year history of usefulness well into the future.

M

IN

W

WDR

WWDR

p

hotos

photos

Bingham Canyon Open-Pit Copper Mine

www.starironworks.com

257 Caroline Street

Punxsutawney, PA 15767

800-927-0560 • 814-427-2555

Fax: 814-427-5164

SERVING THE CONSTRUCTION INDUSTRY

Serving the Drilling Industry

23

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

ExxonMobil - “Carrying the Brand”

Adapted from ExxonMobil Energy Factor

The history of ExxonMobil can be charted largely by the

vehicles that have carried its cargo. The company, starting as

Standard Oil, experienced a decades-long period of growth,

ultimately forming today’s ExxonMobil. Each merger, acqui-

s

ition, or rebrand came with a colorful tale, often told through

ads and logos stamped on the sides of trucks and other

gasoline carriers.

Standard Oil Company of New York (Socony) was one

of the first to use horse-drawn tank wagons. Socony pur-

chased Gilmore Oil Company in 1948, and is one of the her-

itage companies of today’s ExxonMobil. Standard Oil purchased

one-third of Vacuum Oil in 1879; the same year, Vacuum introduced the revolutionary Gargoyle

600-W Steam Cylinder Oil. In the 1930s, the Gargoyle™ brand emblazoned on shiny new gasoline trucks was symbolic of the

Socony-Vacuum Oil Company, which eventually became

Mobil Oil Corporation.

Standard Oil Company used the brand name ESSO

to market products starting in the 1900s; ExxonMobil

continues to market fuel under the ESSO brand in a

number of countries. Jersey Standard bought 50% of

Humble Oil in 1919. Based in Texas, Humble Oil provided

the fuel of choice for notorious playboy and Texan in-

ventor Howard Hughes for use in his planes. Humble Oil

was acquired by Standard Oil of New Jersey in 1959,

and in 1973, Humble Oil became Exxon USA. Mobil 1™ synthetic motor oil, born out of

Socony-Vacuum Oil’s Mobilgrease brand, has been a sponsor brand for sports like Formula 1 and truck racing since 1978.

Today’s ExxonMobil Aviation is one of the world’s largest suppliers of jet fuel for commercial airliners.

Since the ExxonMobil merger in 1999, the company has continued advancing distribution methods for fuels and products.

Gilmore Oil Horse-Drawn Carrier

Gargoyle™ Oil Truck

Anglo American Oil Truck

Humble fueling Hughes’ plane.

G

&

O

Be Aware of Soil Contamination When Installing Soil Borings

Adapted from Information by Talon/LPE

Whether installing soil borings for an environmental investigation or geotechnical purposes, it’s important to keep an eye

out for possible instances where contamination can reach subsurface soil and / or groundwater. Contaminating soil or ground-

water can cause serious safety or legal challenges, which is why it is imperative to consider potential contamination which

may occur with soil borings.

Soil contamination could be present before a project begins, it could

potentially occur during the course of drilling, or after the bore is installed. In

any case, creating new areas of contamination, spreading existing contam-

ination, or creating a pathway for contamination should always be avoided.

It is crucial to find out as much information as possible about cur-

rent site conditions, which will help in choosing the best soil drilling

methods, so conduct a predrilling job walk with the drilling contractor.

Examples of contamination sources or conditions:

• Historic use - Pesticides from farming may linger in soil long

after farming ends. Petroleum hydrocarbons and solvents may

have leaked into soil and groundwater from gas stations or home auto / equipment repair.

• Underground lines and tanks - Utility location services can identify underground lines for sewage to natural gas. Fuel,

heating oil, or waste oil in underground storage tanks may be present but not visible.

• Previous spills - Unusually discolored soil or distressed vegetation may be visible.

• Trash - Toxic or hazardous chemicals may be present in discarded containers, which may be open or leaking.

Steps to help avoid creating new conditions of contamination on the jobsite:

• Entering and exiting sites clean - Drilling equipment should arrive at the jobsite clean. An on-site cleaning station can

clean trucks or other equipment leaving the jobsite.

• Geologic conditions - It is crucial to understand geologic and groundwater conditions at the jobsite.

• Good housekeeping - Properly store toxic or hazardous materials.

• Refueling or maintenance - Use drip pads or pans to avoid spills to the ground. Invest in a spill kit to quickly clean-up

any leak or spill.

• Stormwater drainage - Stormwater runoff can contain vehicle-related chemicals; divert stormwater from soil boring

areas, or seal the top of the borehole.

• After installing the borehole, plug it according to local and state regulations to prevent a pathway for contamination.

25

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

E

N

V

In Memoriam Kenneth Richard “Ken” Gross (1951~2019)

The California Groundwater Association sadly reported the loss of member Kenneth Richard “Ken” Gross

on June 27, 2019, who passed away after a brief illness. Ken was born in Lodi, California, in 1951. He grad-

uated from Galt High School in 1969, then spent six years in the National Guard.

He worked for his father drilling water wells until he started his own business in 1972. Ken ran his com-

pany, Ken Gross Water Well & Pumps, with his wife Diane until his passing. Through his business, he met many

p

eople he was happy to call friends.

Ken enjoyed spending time with family and friends. He was captain of his fishing boat in Bodega Bay, enjoying camping,

crabbing, and fishing. He was especially looking forward to teaching his grandson how to fish. Hunting and trips to Las Vegas,

Reno, and Lake Tahoe were also favorite things to do.

Ken is survived by Diane; daughter Tami (Jarrod); grandson Hudson; son-in-law Klayton; his mother and father Bonnie and

Otto; brother Keith (Gail); and a large extended family. He was preceded in death by his daughter Kendra and his brother Jeff.

A. Richard “Rick” Purchase (1944~2019)

A. Richard “Rick” Purchase of Calais, Vermont, passed away August 14, 2019, surrounded by his family

at the hospital following a sudden, acute illness. Born in Washington, D.C., in 1944, Rick was the eldest of

two sons and grew up in Montpelier, Vermont.

A steadfast Vermonter, Rick graduated high school in 1962, then attended the University of Vermont where

he earned a bachelor of science degree in political science. Soon after, he married Nancy, and they moved to

Calais, to raise their family. They had five children: Kristen (Michael), Kimberly (Robert), Bill, Lt. Col. Kathryn

(Lt. Col. Marc), and Neal (Anne); eight grandchildren Kyle (Shannin), Jack, Elle, Annabelle, Samuel, Henry, Theodore, and Elliot.

Many will remember Rick as an exceptional home builder, general contractor, and owner of Capital Builders, and later the

owner of Johnson Artesian Well Drilling and consultant with Spafford & Sons Water Wells. He was an active volunteer and

community leader, and a member of the Vermont Ground Water Association.

Rick will be remembered for his honesty, kindness, and love of family. He enjoyed gardening, caring for his well-manicured

lawn, and classic cars, particularly Ford Mustangs. Through his years of hard, dedicated work for his employees, customers,

as well as active community involvement, Rick leaves behind a large circle of lifelong friends and colleagues.

The management and staff of

WWDR

WWDR extend their condolences to Ken’s and Rick’s family, friends, and colleagues.

Lest we forget...

26

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

WorldWide Drilling Resource

®

is proud to be a member of these associations.

Alberta Water Well Drilling Association

Tel : 7 8 0-38 6 - 2 3 35

awwda@xplornet.com

A

rizona Water Well Association

admin@azwwa.org

www.azwwa.org

Black Hills Chapter of the ISEE

President: Doug Hoy

www.bitwconference.org

British Columbia Ground Water Assn.

Tel : 6 0 4-53 0 - 8 9 34

secretary@bcgwa.org www.bcgwa.org

California Groundwater Association

Tel : 9 1 6-23 1 - 2 1 34 F a x : 61 4 - 8 9 8-7 7 9 1

www.groundh2o.org

Concrete Sawing & Drilling Association

Tel : 7 2 7-57 7 - 5 0 04

matthew@csda.org

www.csda.org

Empire State Water Well Drillers Assn.

Tel : 3 1 5-33 9 - 8 9 60 F a x : 31 5 - 3 3 9-8 9 6 0

sue@nywelldriller.org

www.nywelldriller.org

Florida Ground Water Association

850-205-5641 Fax: 850-222-3019

djessup@executiveoffice.org

www.fgwa.org

Indiana Ground Water Assn.

Tel : 8 8 8-44 3 - 7 3 30 F a x : 76 5 - 2 3 1-4 4 3 0

ingroundwater@gmail.com

www.indianagroundwater.org

Iowa Geothermal Association

Tel : 5 1 5-22 4 - 6 4 69

info@iowageothermal.org

www.iowageothermal.org

Kentucky Groundwater Association

Tel : 6 0 6 -52 3 - 1 2 15 F a x : 86 6 - 8 9 6-0 184

www.kygwa.org

Louisiana Ground Water Association

Tel : 2 2 5 -74 4 - 4 5 54

www.lgwa.org

Michigan Ground Water Association

Tel : 8 5 5 -22 5 - 6 4 92 F a x : 61 4 - 8 9 8-7 786

www.michigangroundwater.com

Minnesota Water Well Association

Tel : 8 0 0 -33 2 - 2 1 04

www.mwwa.org

Missouri Water Well Association

Tel : 3 1 4 -97 4 - 6 9 92

Mwwa.MoWaterWellAssociation@yahoo.com

Montana Water Well Drillers Association

Tel : 4 0 6-68 6 - 3 1 68

www.mwwda.org

National Drilling Association

Tel : 8 7 7-63 2 - 4 7 48

Fax: 216-803-9900

www.nda4u.com

National Ground Water Association

Tel : 8 0 0-55 1 - 7 3 79 F a x : 61 4 - 8 9 8-7 7 8 6

www.ngwa.org

Nebraska Well Driller Association

Tel : 4 0 2-47 6 - 0 1 62

lee@h2oboy.net

www.nebraskawelldrillers.org

New Jersey Ground Water Association

barbemor@gmail.com www.njgwa.org

North Carolina Ground Water Assn.

Tel : 9 1 9-87 6 - 0 6 87 e l a i ne@ e x e c man. n e t

www.ncgwa.org

North Dakota Well Drillers Association

Tel : 7 0 1-56 7 - 4 1 26

ndwda@outlook.com • www.ndwda.com

Northern Plains Chapter of the ISEE

President: Billy Obermire

Tel : 3 0 7-68 9 - 0 0 50

www.bitwconference.org

Ohio Water Well Association, Inc.

Tel : 9 3 7-27 8 - 0 3 08 F a x : 93 7 - 2 7 8-0 3 1 7

www.ohiowaterwell.org

Oklahoma Ground Water Association

Tel : 4 0 5-20 9 - 6 4 82

josh@okgroundwater.org

www.okgroundwater.org

Ontario Groundwater Association

Tel : 5 1 9-24 5 - 7 1 94 F a x : 51 9 - 2 4 5-7 1 9 6

executivedirector@ogwa.ca

www.ogwa.ca

Pennsylvania Ground Water Association

Tel : 8 1 4-55 3 - 3 8 83

pgwaorg@gmail.com www.pgwa.org

Shallow Exploration Drillers Clinic

Tel : 4 0 2-47 2 - 7 5 50

jloomis3@unl.edu http://sedc.unl.edu

S

outh Atlantic Well Drillers “JUBILEE”

Tel : 8 5 5-98 7 - 7 4 69 F a x : 85 0 - 2 2 2-3 0 1 9

kgordon@executiveoffice.org

www.jubileewatershow.com

South Carolina Ground Water Association

Tel : 8 0 3-35 6 - 6 8 09 F a x : 80 3 - 3 5 6-6 8 2 6

scgwa@sc.rr.com www.scgwa.org

South Dakota Well Drillers Association

Tel : 6 0 5 -73 4 - 6 6 31 w w w. sdw d a . o r g

Southwest Mississippi Community College

Well Construction Technology

Tel : 6 0 1-27 6 - 3 7 38

cdunn@smcc.edu

Ten n e s s e e Wa t er Wel l A s s o ciat i o n

Tel : 8 6 5-76 1 - 4 3 63

tnwaterwellassociation@gmail.com

Tex a s A l l ian c e o f En e r g y Pr o d u c e rs

Tel : 9 4 0-72 3 - 4 1 31 F a x : 94 0 - 7 2 3-4 1 3 2

joannb@texasalliance.org

www.texasalliance.org

Tex a s G roun d Wat e r A s s oci a t i o n

Tel : 5 1 2-47 2 - 7 4 37 F a x : 51 2 - 4 7 2-0 5 3 7

drobbins@twca.org www.tgwa.org

Utah Ground Water Association

Tel : 8 0 1 -54 1 - 7 2 59

www.utahgroundwater.org

Vermont Ground Water Association

Ken White, President: 802-738-8400

kwhite.vaw@gmail.com

Margaret Laggis, Executive Secretary

laggistics@comcast.net

Virginia Water Well Association

Tel : 8 0 4-38 7 - 8 3 95 F a x : 80 4 - 3 0 2-7 9 7 8

info@vawaterwellassociation.org

www.vawaterwellassociation.org

Your

WWDR Team

WWDR Team is working on the

2020 Marketing Guide!

Let our Public Relations Professionals

create a personlized marketing plan

for your business in 2020.

850-547-0102

Ed@

worldwidedrillingresource.com

27

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

28

OCTOBER 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

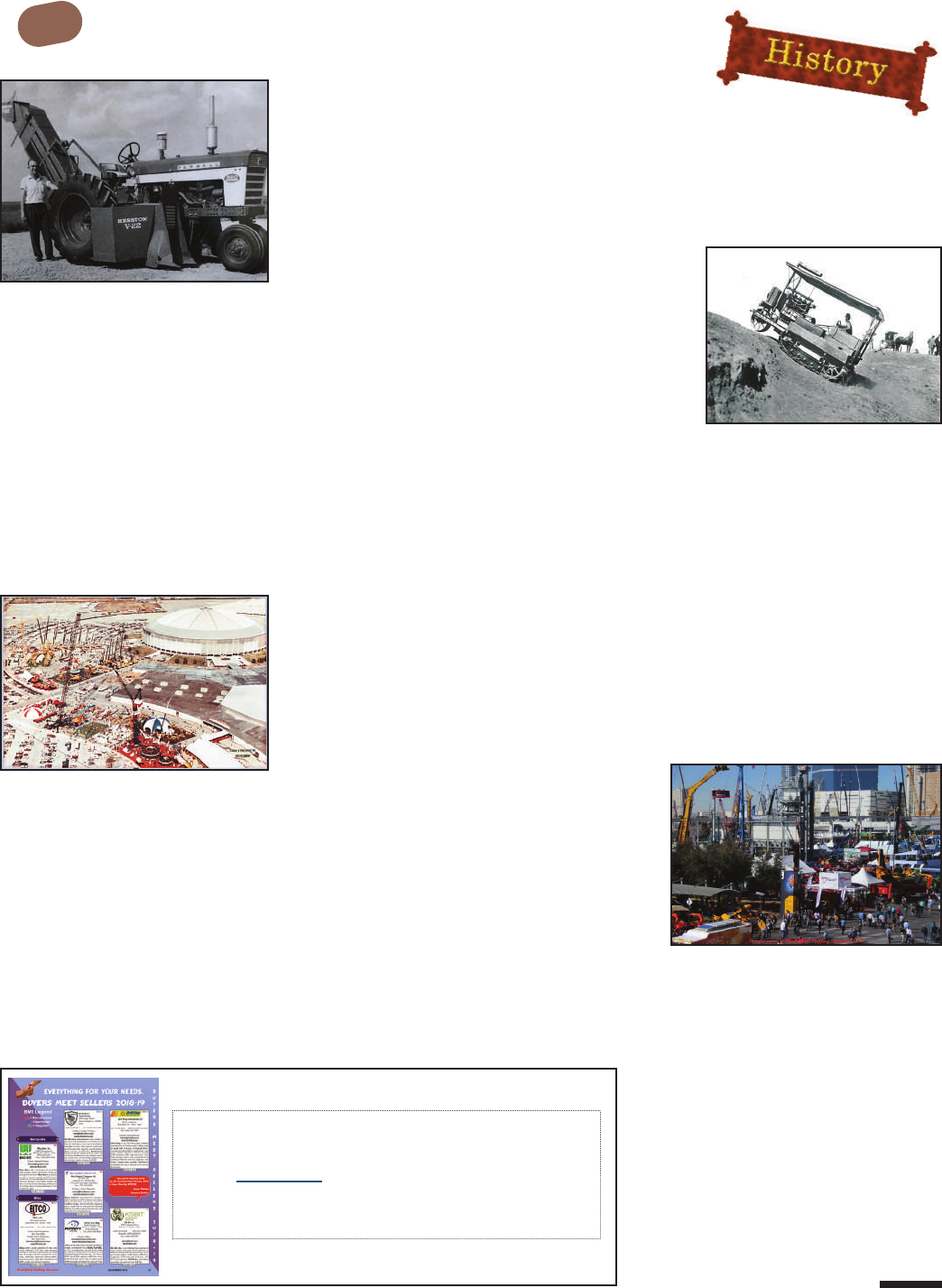

AEM - Leadership for Over a Century

A

dapted from Association of Equipment Manufacturers

The Association of Equipment Manufacturers’ (AEM)

robust history began 125 years ago from a unique vantage point

- its industry segments came together to create a fundamentally more powerful

voice and advocate for the off-road equipment manufacturing industry. For more than a

century, the AEM has provided a manufacturer forum for industry-wide action transcend-

ing individual member company size, product line, or individual business concerns. Companies

participating in AEM work together for the betterment of the industry and public needs

at the state, national, provincial, and international levels.

A

EM built on the successes and continued the

legacy of its founding groups - the Construction Industry

Manufacturers Association (CIMA) and the Equipment

Manufacturers Institute (EMI). Both groups had a common goal - advocating for better roads

that brought products to market faster, safer, and more efficiently. Today, AEM continues to

make noise in Washington, and a key issue is still the need for a superior infrastructure sys-

tem for improved productivity and quality of life.

Let’s take a trip back in time to view AEM’s significant milestones and contributions:

3 1894 - National Association of Agricultural Implement and Vehicle Manufacturers

(NAAIVM) was established. Several name changes followed to reflect shifts in industry.

3 1911 - The first formal meeting of what eventually became CIMA was a November gathering of the National Association

of Material and Machinery Manufacturers (NAMMM).

3 1948 - American Road Builders Association sponsored the Road Show, predecessor of today’s CONEXPO-CON/AGG.

The first Road Show at Soldier Field in Chicago, Illinois, post World War II was larger and more diverse than any previous

shows.

3 1956 - The “Combined Biennial Show,” predecessor of CON/AGG, was held at Chicago Coliseum.

3 1960s - In 1966, the forerunner of International Construction & Utility Equipment Exposition (ICUEE), known as the “Elburn

Show,” was held in a field in Elburn, Illinois. Later in 1969, CIMA introduced its first safety

manual.

3 1970s - CIMA broadened its membership to include companies from around the world

in recognition of the increasingly global scope of the industry.

3 1980s - EMI became ICUEE show owner and producer after providing industry direc-

tion and was first held in Louisville, Kentucky, in 1987. The Farm and Industrial Equipment

Institute (formerly NAAIVM) made their final name change to the Equipment Manufacturers

Institute in 1989.

3 1990s - In 1997, CIMA opened an office in

China. CONEXPO-CON/AGG became the United

States’ largest trade show across all industries in1999.

3 2000+ - In 2001, World of Asphalt was first held and rotated between cities in

the United States. International Fluid Power Exposition (IFPE) was colocated with

CONEXPO-CON/AGG in 2002. Previously, the show was held in Chicago, begin-

ning in 1984. Additionally, the CIMA and Equipment Manufacturers Institute consoli-

dated into the Association of Equipment Manufacturers (AEM). Branching out in

2004, AEM opened its Canadian office. In 2015, CONEXPO -CON/AGG in Latin America

was held for the first time in Santiago, Chile. In 2017, the “Thinking Forward” event

series introduced members to a vision of the future as they prepare to face critical

challenges to their busnesses. AEM acquired data analytics company Hargrove &

Associates in 2018. Most recently in 2019, AEM became a partner and member of Commodity Classic’s management

committee.

As AEM celebrates its past leader-

ship success, the association remembers

its basic tenets of information, connec-

tion, insight, and action as it looks for-

ward to the next 125 years.

Make plans to attend the

2020 CONEXPO-CON/AGG

in Las Vegas, Nevada,

March 10-14.

C

&

G

WWDR

WWDR

photo of CONEXPO-CON/AGG in

2017.

Don’t Miss This Great Opportunity!

Call Now: 850-547-0102

Annual Buyers Meet Sellers!

Printed in the December issue and available online

(with a direct link

to your website) all year long, plus

trade show distribution.

All for one low price!

29

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

OCTOBER 2019

Notes from the Groundwater Guy

by Thomas E. Ballard, P.G., C.H.G.

Southeast Hydrogeology, PLLC

Common Causes of Well Failure - Well Design and Construction

We look at many examples of problem wells around the country, and some common themes stand

out. One of the most common causes of well failure is in the well design and construction process. The

six main areas where we see issues with well construction and design are:

1. Well Seals: Many wells are constructed using state standards as de facto construction standards when geology should

really be the guide. We find that problems with things like nitrates and total coliform are often directly traceable to inade-

quate seal depth.

2. Screen and Casing Materials: It may seem like a great idea to save money on a well using low-carbon steel casing

and stainless steel screen, but you are really setting yourself up for galvanic corrosion of the low-carbon steel, substantially

shortening the life span of the well. Using dissimilar metals in a well without a dielectric coupling.

3. Screen and Gravel Size: The wrong choices here can lead to a sanding well if the screen openings are too large and

the gravel not sized appropriately for the screen. Similarly, too small of a screen opening can lead to an inefficient well

which is also challenging to develop properly.

4. Bridging Issues: Installation of gravel pack during well construction can result in voids due to bridging, which can result

in later sanding issues. Settling can have a similar effect, if inadequate gravel is placed over the top of the upper screen

section, settles during development, and well use causes the top of the gravel to drop below the top of the upper screen

section.

5. Welds: Welds are a common point of failure due to preferential corrosion of welds due to differences in metal types.

Video logs of wells should be conducted after well completion to verify construction, and later video logs should pay at-

tention to welds to check for corrosion issues.

6. Plumbness and Alignment: A well that is not straight and plumb will often have problems with construction and pump

operation, although submersible pumps can be a bit more tolerant of well deviation than turbine pumps.

Most of these issues can be addressed by paying attention to the geology while drilling or, even better, understanding the