Breaking News..................................................................13

Classified Section:

WorldWide SUPER MART™

WorldWide SUPER MART™..................48-64

Dealmakers........................................................................14

Education Connection......................................................37

Fun Page............................................................................37

Hot Off the Press.................................................................9

Industry Announcements.................................................24

News Flash........................................................................23

Obituary: Barlow, David Eugene......................................28

Obituary: Geisser, III, George John.................................28

Photo Gallery............................................................21,30,35

Product Spotlight..............................................................32

Where are you planning to go?........................................19

Who’s in the News.............................................................13

WorldWide Association Memberships

WorldWide Association Memberships................................39

WorldWide Business Directory™

WorldWide Business Directory™.............................10,11,12

WorldWide

WorldWide

.........6

Editorial Focus for August -

Environmental

C&G

DIR

ENV

EXB

G&O

GEO

MIN

WTR

Acker Drill Company...........................................................42

Allegheny Instruments........................................................27

America West Drilling Supply..............................................60

AMS, Inc.............................................................................35

Armstrong Machine Co., Inc. (AMCI)..................................46

Atlantic Screen & Manufacturing, Inc. (ASI)........................37

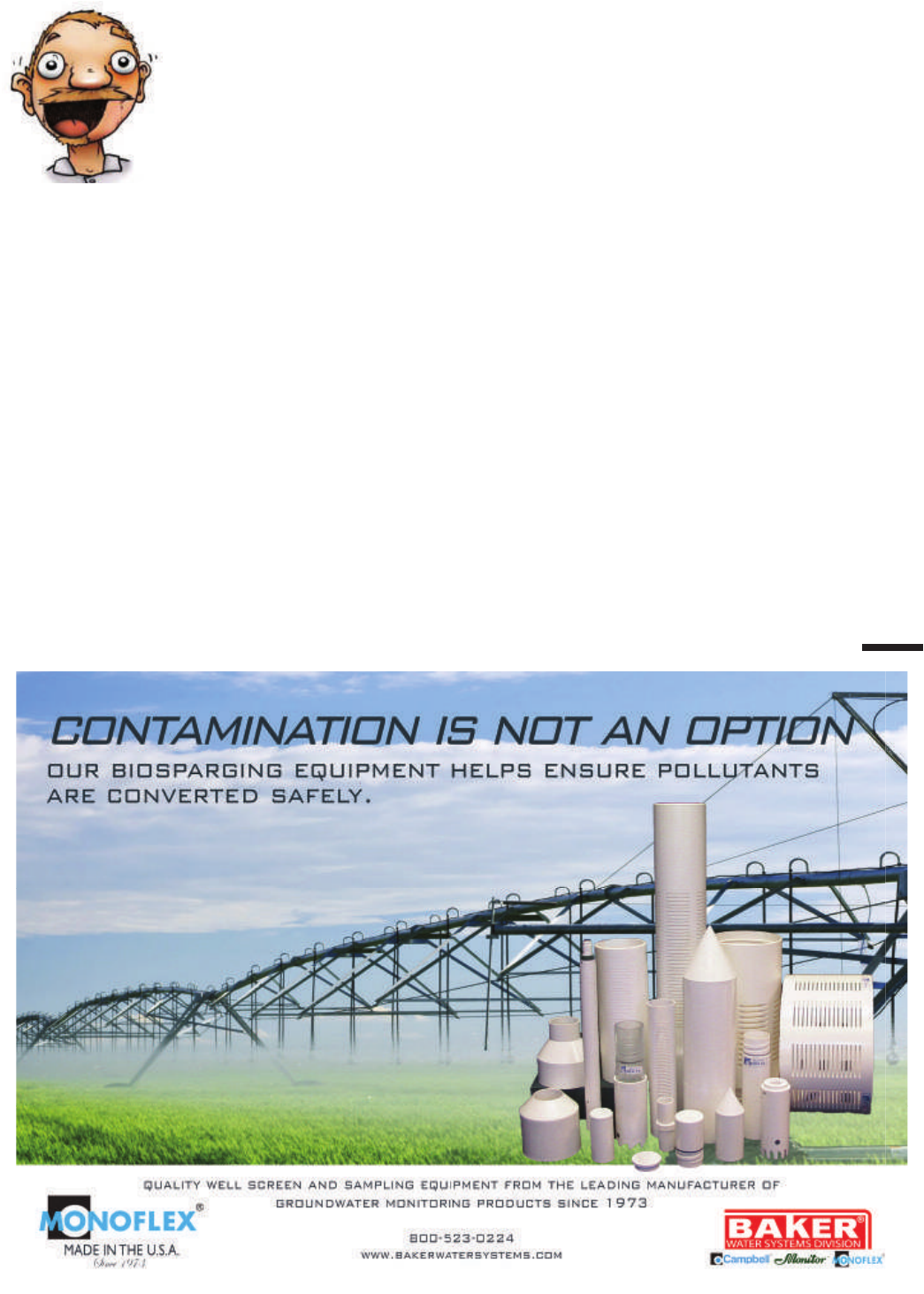

Baker Water Systems.........................................................38

Better Water Industries, Inc.................................................29

Bill Johnson Equipment Company......................................13

Bitco, Inc.............................................................................19

Bloom Mfg., Inc...................................................................44

California Groundwater Association (CGA) Convention........9

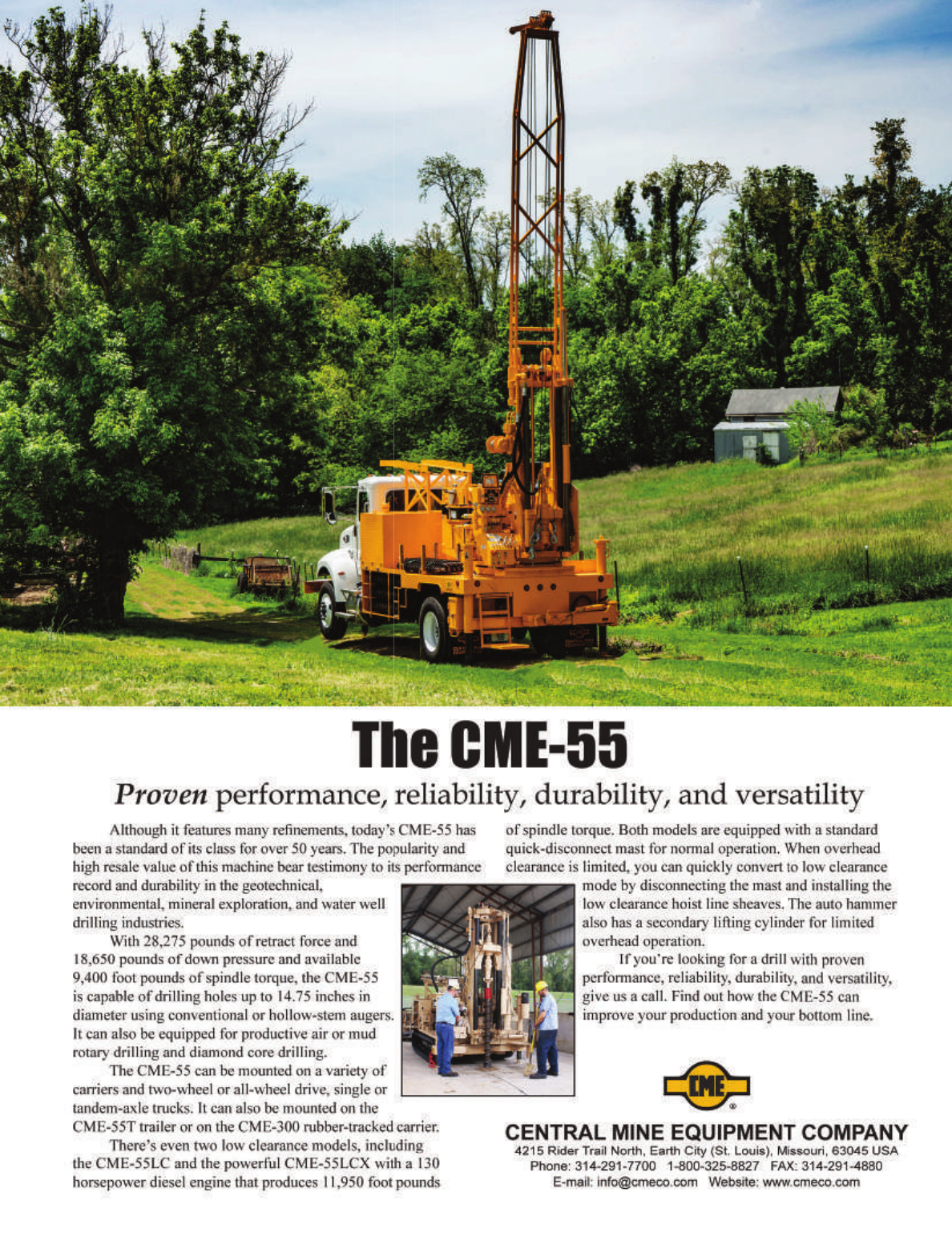

Central Mine Equipment Company (CME)..........................47

CONEXPO-CON/AGG

®

......................................................26

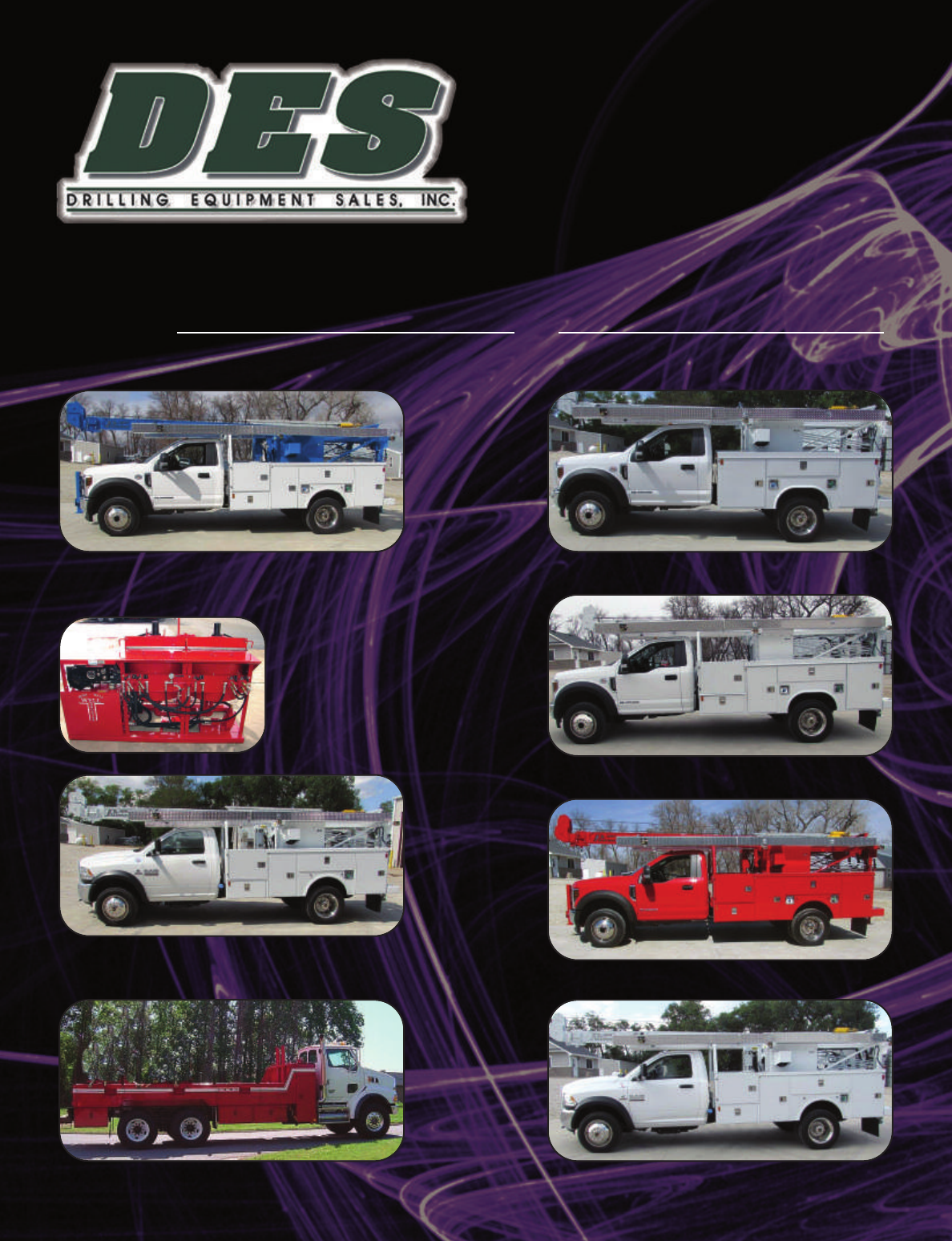

Drilling Equipment Sales, Inc. (DES)..................................63

Drilling Supply & Mfg (DSM)...............................................18

DRILLMAX

®

..........................................................................2

Eijkelkamp/SonicSampDrill.................................................22

Flomatic

®

Corporation.........................................................61

Foremost Industries............................................................28

GEFCO, Inc. (an Astec Industries Company).....................64

Geoprobe Systems

®

............................................................31

Geothermal Supply Company, Inc. (GSC)..........................23

Grundfos Pumps Corporation.............................................15

Industrial Test Systems (ITS), Inc.......................................30

Infinity Tool Manufacturing....................................................3

International Construction & Utility Equip. Expo (ICUEE)...62

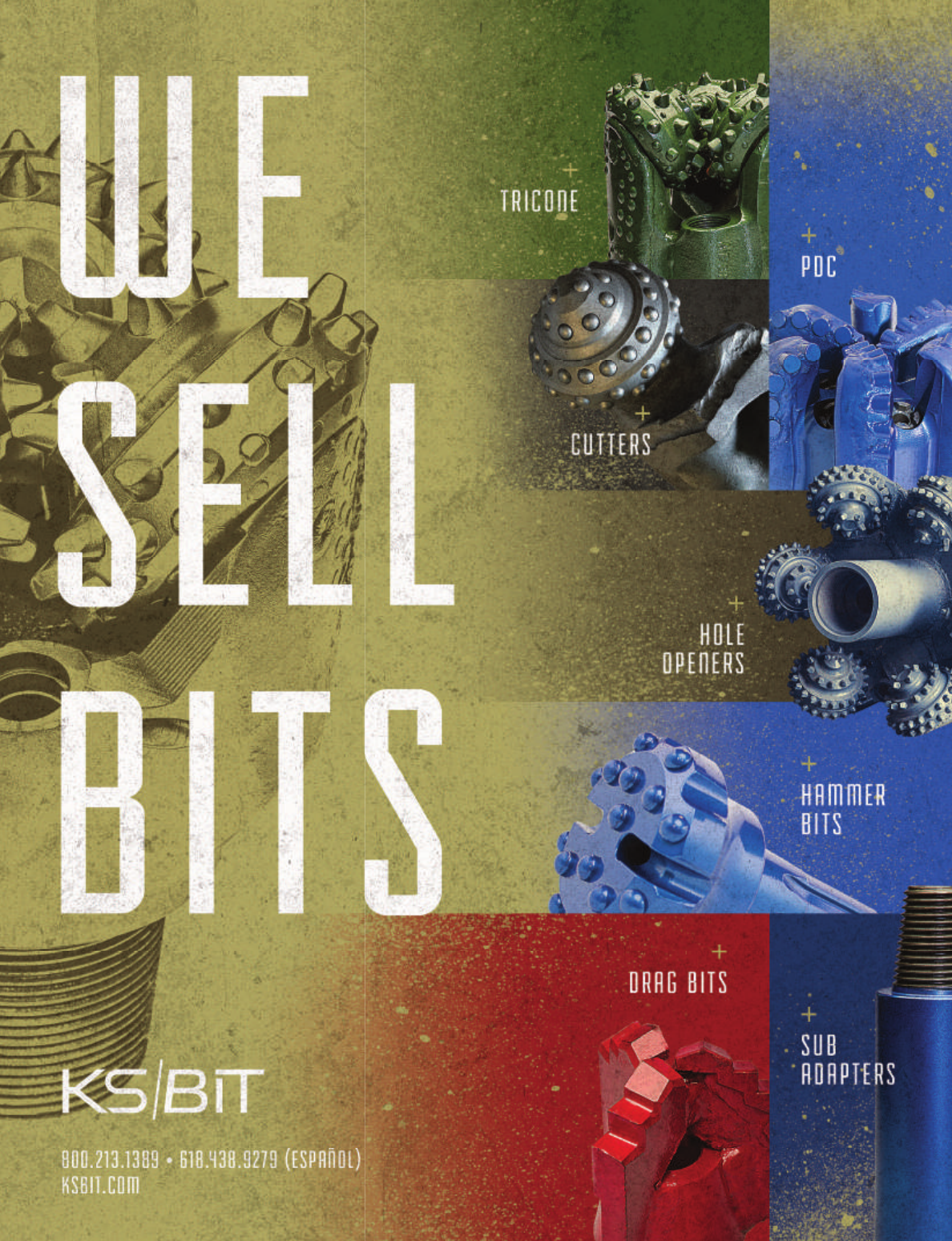

KS Bit, Inc...........................................................................34

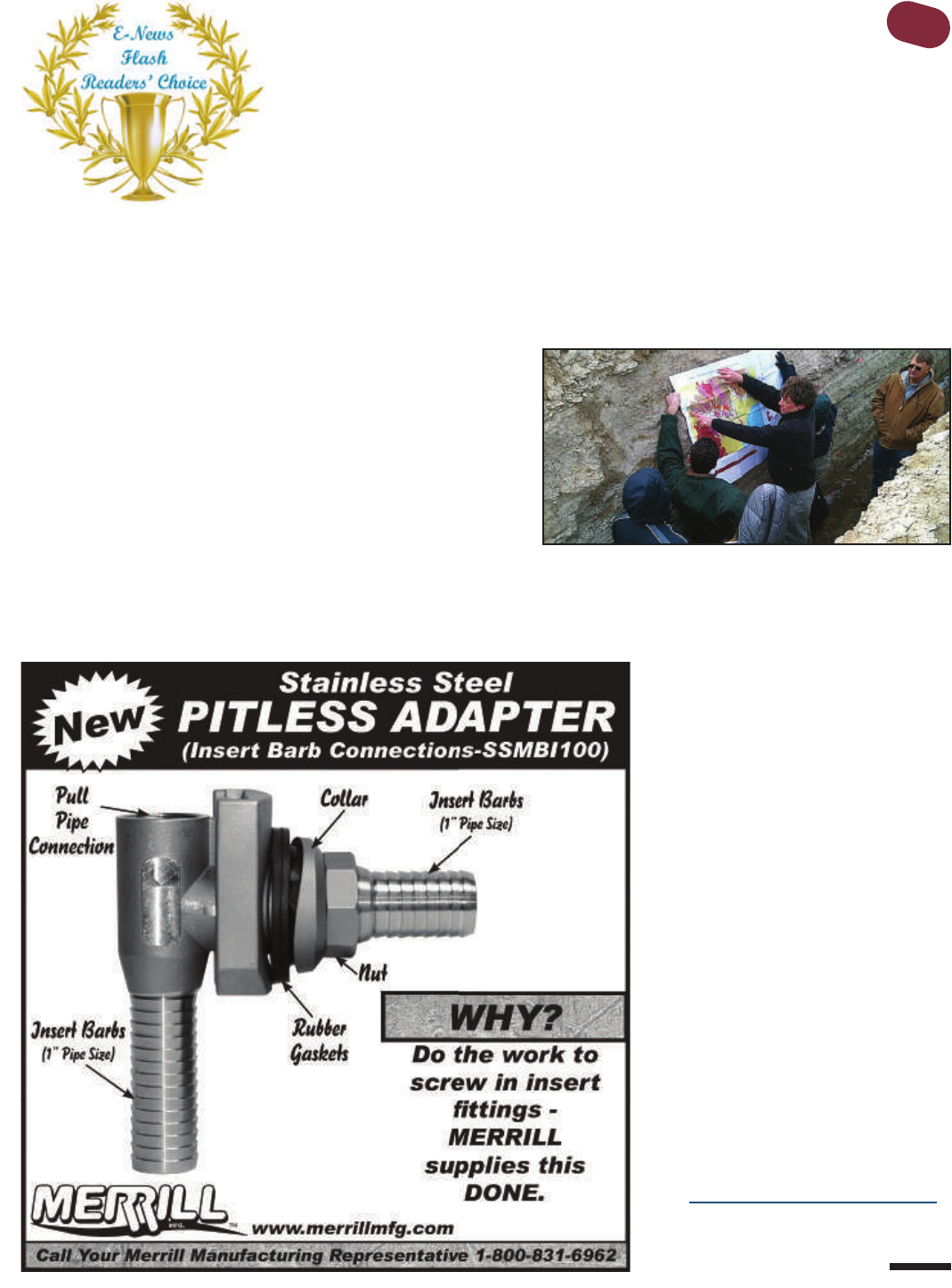

Merrill Mfg...........................................................................40

Mills Machine Company, Inc...............................................36

N&N Drilling Supply.............................................................20

National Drilling Association (NDA) Convention……..........16

Palmer Bit Company.............................................................8

Seametrics..........................................................................41

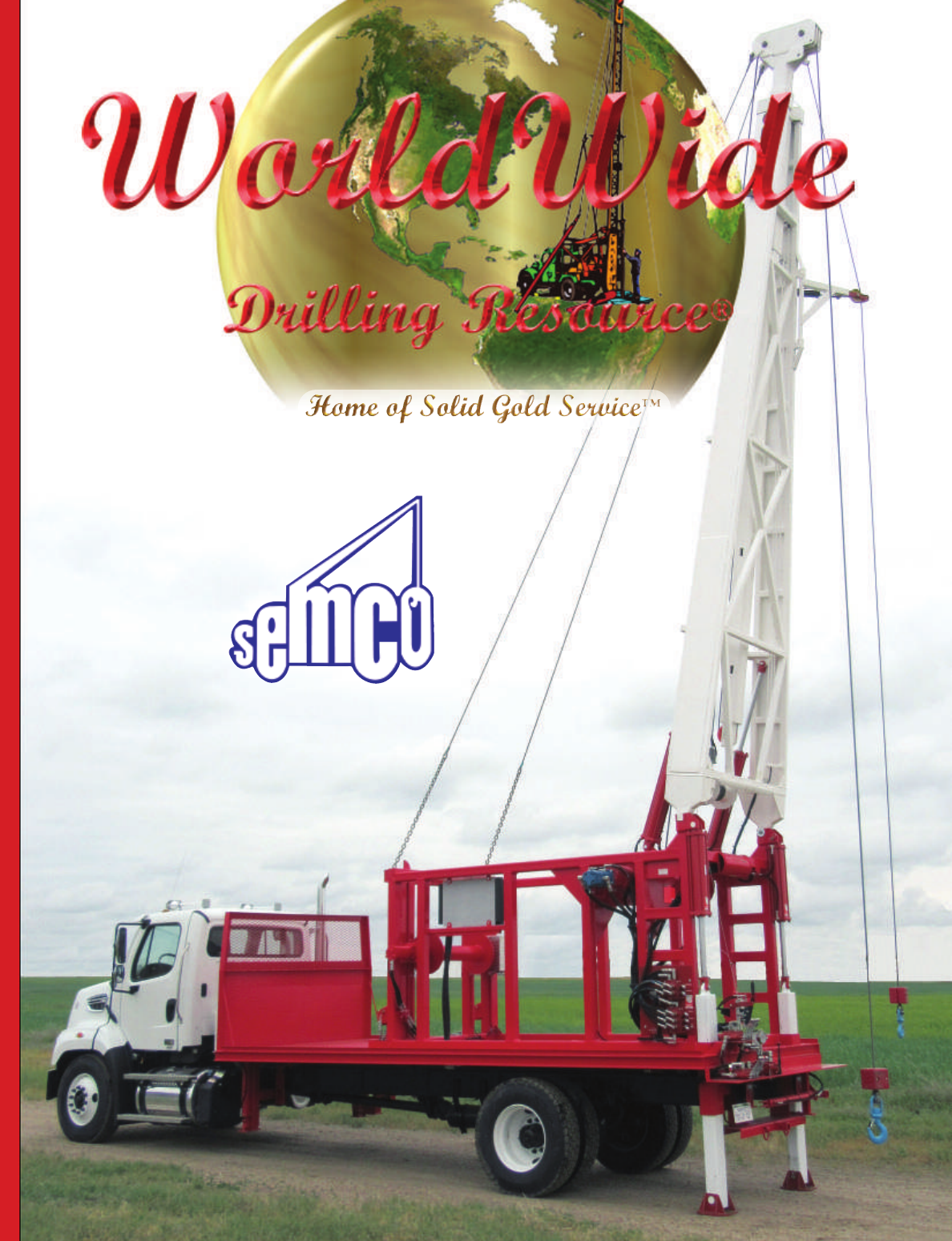

SEMCO, Inc..........................................................................1

SIMCO

®

Drilling Equipment...................................................4

Sonic Drill Corporation........................................................32

Star Iron Works, Inc............................................................24

Star Iron Works, Inc............................................................25

TDH Manufacturing Inc.......................................................45

Throop Rock Bit Company..................................................43

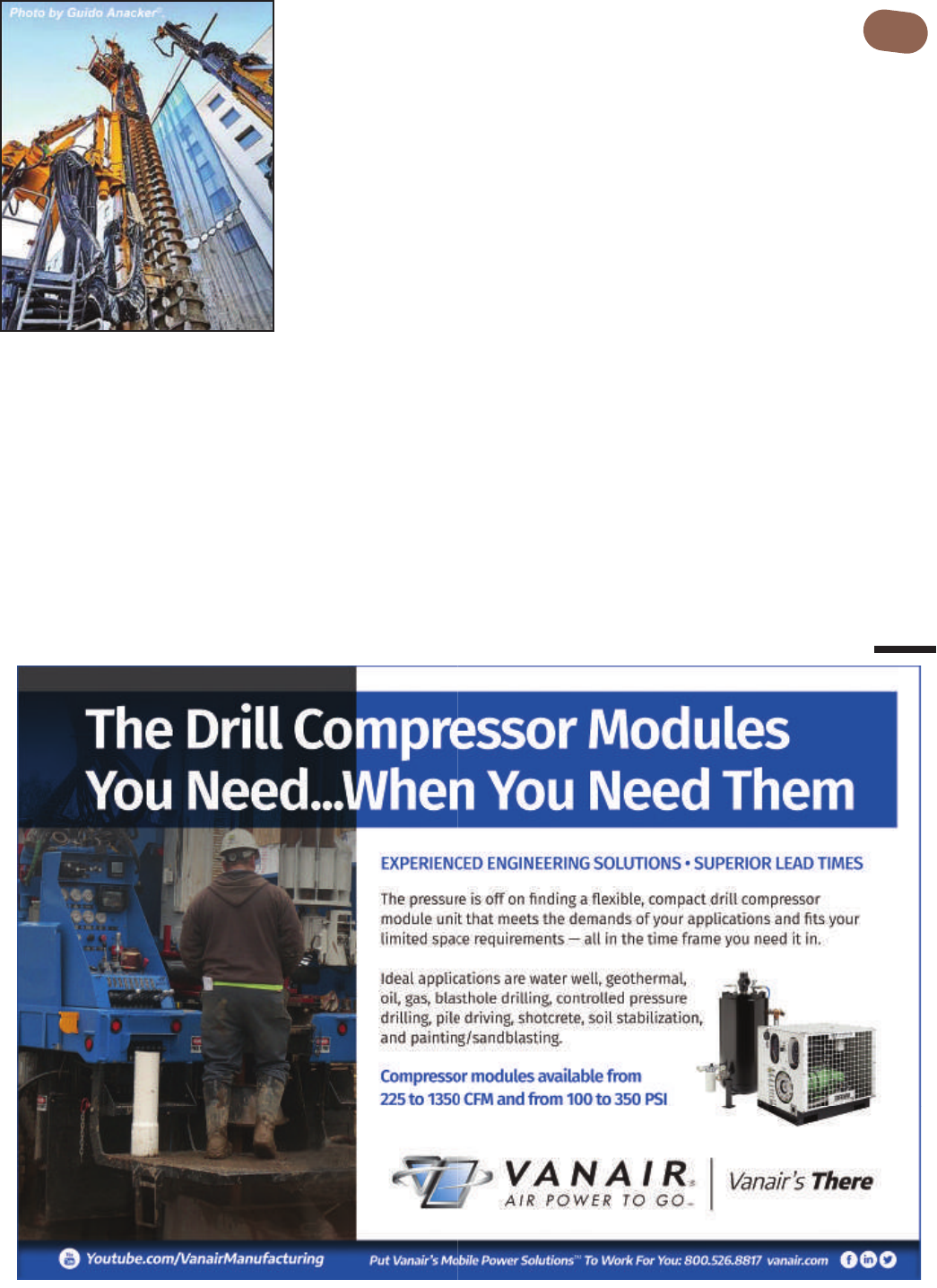

Vanair Manufacturing, Inc.....................................................7

Well-Vu, Inc.........................................................................33

Wyo-Ben, Inc......................................................................17

Advertisers

Featured Editorial:

C&G - Construction/Geotechnical

ENV - Environmental

G

&O - Shallow Gas and Oil

M

IN - Mining

D

IR - Horizontal Directional Drilling

EXB - Exploration/Blasthole

GEO - Geothermal

WTR - Water

Specialist Foundation Engineering for Düsseldorf’s....7

Storkson, Britt: Partial Failure = Total Failure..........33

The Futue of Tire Management - Intelligent Tires......44

Wilson, Jr., Robert Evans: The Un-Comfort Zone II..14

First Multilateral Well Drilled in India.........................29

A Mammoth Find.......................................................16

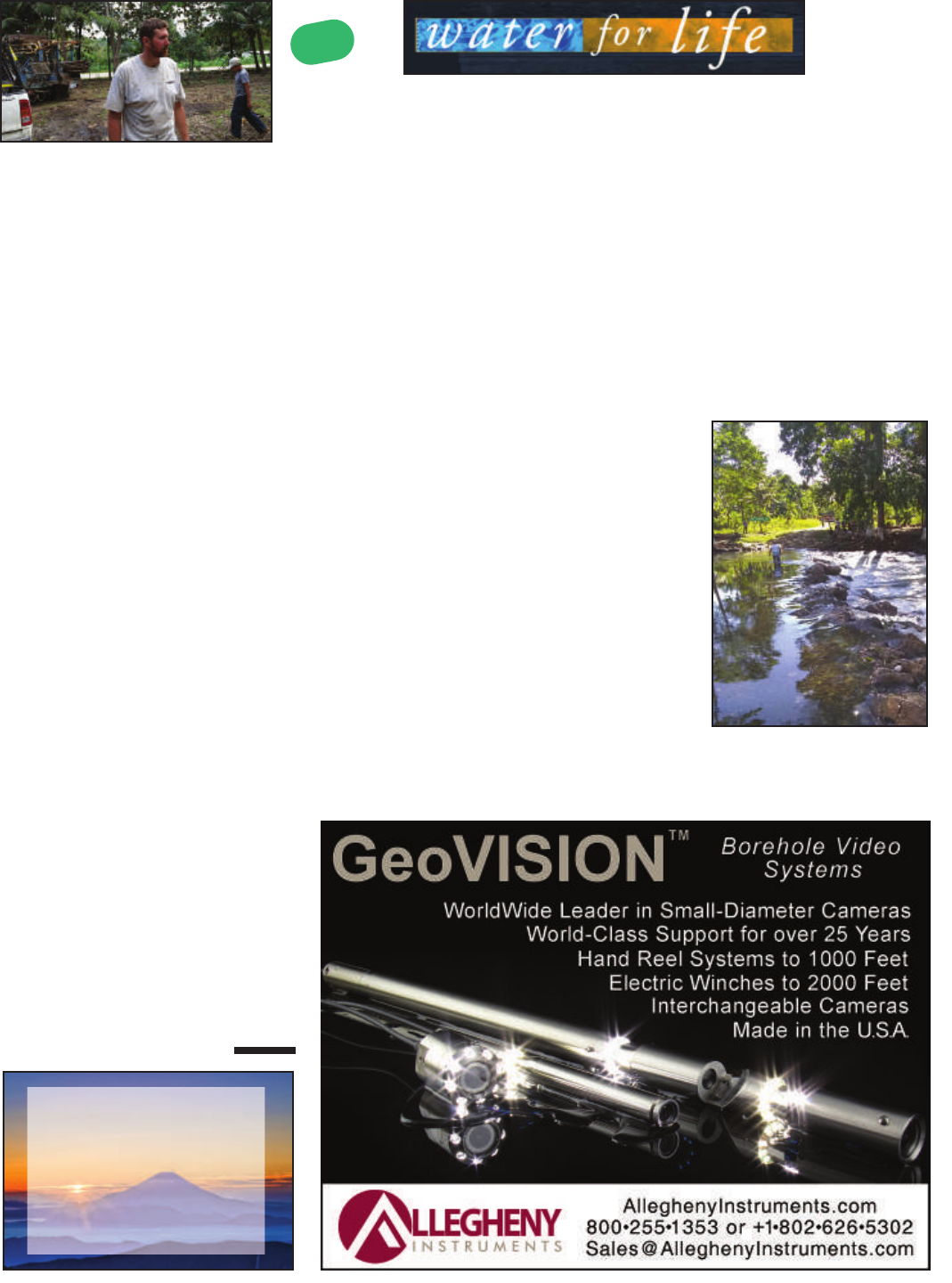

Rasmussen, Tim: Water For Life International........27

Kwader, Thomas: Environmental Monitoring...........32

White, Harold: Oil/Water Exploration.......................12

The World’s First Electric Autonomous Blasthole Drill..36

Wire, Jeremy C.: Tales from the Field......................46

New Model May Lead to More Efficient Hydraulic.....17

What Happened in Pittsburg County, Oklahoma?.....23

Battersby, Mark E.: Drilling Into Money Not Boring..43

Game-Changing Technology for Geothermal Drilling?...20

Connor, Tim: Get Over It..........................................29

E-News Flash

E-News Flash

Readers’ Choice

Readers’ Choice: Geothermal Power......40

Simulator Use Improves Results in North America....21

Winds of Change......................................................30

“Smith, Billy Bob”: The “Idiot’s” Corner..................38

Ballard, Thomas: Notes from the Groundwater Guy..19

Everett, Edward E.: A Consultant’s Perspective....25,44

Flomatic

®

~ Celebrating Their Expansion..................35

Water Wells After the Flames....................................41

5

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

P

roudly

Ma

de

in

the

Unite

d

S

ta

te

s

of Ame

ric

a

-

de

liv

e

re

d

WorldWide

WorldWide

!

!

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

The

c

ompl

e

t

e

magaz

ine

fo

r

th

e

dr

illin

g

in

dus

t

r

y

worl

dwide, owned by

drilling industry associates dedicated to bringing the most up-to-date

t

e

c

h

n

o

l

o

g

y

a

n

d

i

n

f

o

r

m

a

t

i

o

n

t

o

s

u

b

s

c

r

i

b

e

r

s

.

Co

v

e

r

i

n

g

const

r

uct

ion-

g

e

o

t

e

c

h

n

ic

a

l

,

d

ir

e

c

t

io

n

a

l

,

e

n

v

ir

o

n

me

n

t

a

l

,

e

x

p

lo

r

a

t

io

n

-

b

la

sthole

,

shallow

ga

s

& oi

l

,

ge

ot

he

r

m

a

l

,

m

i

ni

ng

,

wa

t

e

r

we

ll

,

ir

r

ig

a

t

io

n

,

wa

s

t

e

wa

te

r

; fro

m b

its

, to

p

u

mp

s

, to

r

ig

s

, to

ta

n

k

s

, th

r

o

u

g

h

wir

e

,

a

n

d

m

o

r

e

-

wha

t

e

v

e

r

i

t

t

akes t

o get

t

he

dr

i

l

l

i

ng

j

ob

c

om

pl

e

t

e

d

!

M

a

na

gi

n

g

Publish

er/

C

EO/

Pre

side

nt:

Veronica I. “Ro

nn

i

e

” Jo

nes

Vice President:

Troy Cunningham

C

h

i

e

f

M

a

rke

t

i

n

g

Of

f

i

ce

r:

Ed

M

o

ra

n

ski

Of

f

i

ce

Ad

m

i

n

i

st

ra

t

o

r:

M

i

ch

e

l

e

St

e

ve

n

s

Ed

i

t

o

r:

Bo

n

n

i

e

L

o

ve

Asso

ci

a

t

e

Ed

i

t

o

r:

C

a

l

e

b

Wh

i

t

a

ke

r

Public Relat

ions Prof

essionals:

Kat

hy Heinrich

Jan Allen

Production/Webmaster: Marcel Schimpf

Representative:

Marie Cunningham

Editorial Contributors for this month:

Tom Ballard Mark Battersby Tim Connor Edward E. Everett

Thomas Kwader

Tim Rasmussen “Billy Bob Smith” Britt Storkson

Harold White Robert Evans Wilson, Jr. Jeremy Wire

Hyd/Eng Consultant:

Thomas Kwader, Ph.D.,P.G.

Consultant:

Mary Ann Pelletier

*

Editorial contributions & advertisements include statements of fact and opinions

that are the sole responsibility of the author and/or companies and do not

necessarily imply any opinion of the owners, management, or staff of

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

.

Images may have been altered for clarity.

Complete advertising information may be found at:

www.worldwidedrillingresource.com

or by calling 850-547-0102.

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

makes every

effort

not

to place advertisements for “like” products on the same page in our

publication; this may occur however, due to size and space within the publication.

We regret any inconvenience this may cause our advertisers.

W

o

r

l

dW

ide

D

r

il

l

in

g

Re

so

ur

c

e

W

o

r

l

dW

ide

D

r

il

l

in

g

Re

so

ur

c

e

®

®

i

s

p

u

b

lis

h

e

d

m

o

n

th

ly

b

y

:

WorldWide Drilling Resource, Inc.

, a Florida Corporation

PO Box 660 (

3089 Nor

thr

ide Lane)

Bonifay FL 32425-

0660.

Telephone: 850-

547-

0102 Fax: 850-

547-

0329

E-

mail: wwdr

@wor

ldwidedr

illingr

esour

ce.com

Website: www.wor

ldwidedr

illingr

esour

ce.com

Copyr

ight

2019,

WorldWide Dr

illing Resource, Inc.

Seen by countless

WorldWide

. Publication Agreement No. 40892520. Back issues may be

requested. Cost per issue $10.00 USD. No part of this publication may be

r

epr

oduced in any manner

without the str

ict wr

itten consent of the publisher

s.

Adver

tising

r

ates

fur

nished

upon

r

equest.

Editor

ial

contr

ibutions

ar

e

welcome

subject to editor

ial r

eview.*

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

reser

ves the

right to refuse any advertisement

.

We

We

Re

c

y

c

le

Re

c

y

c

le

Short, Sweet, and to the Point . . .

The days turn into weeks, turn into months, turn into years, and just seem to fly by just

when we think, “Gosh, I have all the time in the world.” Well, it’s about time we all get moving and

enjoy what is around us ~ take a walk on the beach, a

stroll through the park, a quiet walk down memory lane,

or why not just fly a kite and DREAM!

Nostalgic? Yes, it’s true, and I bet each of us do that from time

t

o time. Anything wrong with that? I say no. It’s a way of staying sane

in a world that is absolutely flying by around us. So join in.

As I sit here at my desk, its going on 5:00 p.m. Central Time, I wonder - what else can we do to let you know

just how much we care about this drilling industry and all those in it? For the life of me, I just don’t know. This

WWDR

WWDR Team works so very hard each and every day, and sometimes half the night for ways to help you.

So, I pose that question to you here and ask for your help in answering it. What else can we do?

Accept NO imitations - there is only one true

RESOURCE

RESOURCE. 850-547-0102

One more very important thing ~ I so value everyone out there in “drilling land” for dropping me personal notes.

Mrs. Lepley, yours commenting on July’s

Ronnie’s Real World, touched my heart. I know it was hard

to say and filled with emotions. May your husband Bob rest in peace, and your son, Joe find

you. I sincerely thank you. God Bless You and Keep You Safe.

Yes, the things (people) we take for granted, believing they will be there forever. How quickly they aren’t.

W

e

W

i

l

l

S

e

e

y

o

u

o

n

t

h

e

t

r

a

i

l

!

N

E

X

T

S

T

O

P

~

N

D

A

,

P

i

t

t

s

b

u

r

g

h

With pen

(computer) in hand .

. .

Ronnie, Managing

Publisher

ronnie@worldwidedrillingresource.com

~ From the Cover ~

~ From the Cover ~

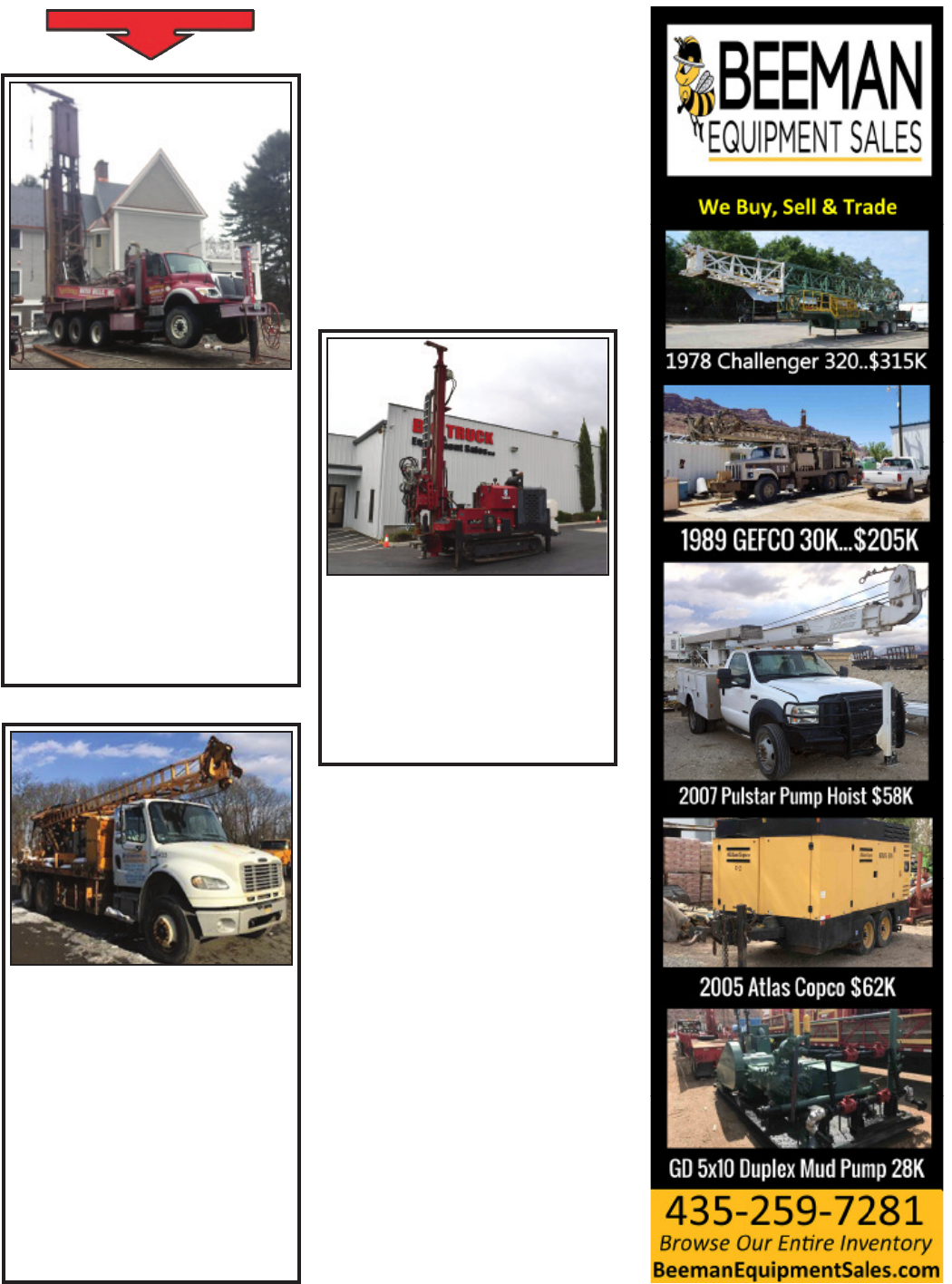

Thank you to our repeat neighbor: Dreiling Pump Supply

Thank you to our repeat neighbor: Dreiling Pump Supply

Rick Dreiling - located in Fort Collins, Colorado

Rick Dreiling - located in Fort Collins, Colorado

SEMCO S15,000 Pump Hoist, 48' derrick, upper-mount drawworks, 2000-foot capacity sandreel,

hydraulic oil cooler dual fans, auxiliary hydro valve, 2-speed winch w/grooved drum, power arm,

LED light kit for mast, behind-the-cab outriggers, factory mounted on customer's 2019

Freightliner 108SD with custom flatbed.

SEMCO INC.

SEMCO INC.

PO Box 1216 • 7595 US Hwy 50 N

PO Box 1216 • 7595 US Hwy 50 N

Lamar CO 81052-1216

Lamar CO 81052-1216

719-336-9006 • Fax: 719-336-2402

719-336-9006 • Fax: 719-336-2402

E-mail: semcopumphoist@gmail.com

E-mail: semcopumphoist@gmail.com

www.SEMCOoflamar.com

www.SEMCOoflamar.com

6

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Specialist Foundation Engineering

for Düsseldorf’s Tallest Residential Tower

Adapted from Information by BAUER Group

With a population of about 617,000, the North Rhine-Westphalian capital Düsseldorf

is the seventh largest city in Germany. To meet the growing demand for living space,

the UpperNord Tower, a modern residential development, is currently being built. Located

a

t the northern entrance to the city, the 390-foot-high residential tower will be the tallest

of its kind in Düsseldorf. The UpperNord Tower will have 36 floors, with the majority of

the space being used for 432 planned residential units. It will also include a variety of

restaurants on the ground floor, a three-story underground parking garage, and a five-

story hotel, which will adjoin the building.

The client, UpperNord Tower GmbH & Co. KG, a member of CG Group AG, con-

tracted the joint venture, which consists of BAUER Spezialtiefbau GmbH and Gerhard

Kliemt GmbH, to carry out a variety of specialist foundation engineering and earth

works, as well as construct the dewatering system for the impermeable retaining structure of the UpperNord Tower.

Around 19,600 square feet of shoring wall for the retaining structure was constructed using the low-vibration mixed-in-

place (MIP) method, which involves mixing the existing soil in-situ with a binding agent. A triple continuous flight auger was

used to produce a homogeneous soil concrete. By using the embedded soil as a building material, there are economic and

ecological advantages over conventional shoring, and resources are conserved. One challenge for the project was drilling to

depths of nearly 80 feet, but such depths wouldn’t have even been possible with the MIP equipment from several years ago.

An RG 25 S from RTG Rammtechnik GmbH, a subsidiary of BAUER Maschinen GmbH, was used for the MIP work. In

addition, an RG 16 was used to install 700 tons of reinforcement in the form of inserted double steel beams. This reinforcement

is another special feature of the construction project.

To secure this impressive excavation, additional anchors with three to six strands were installed. A KR 806 from KLEMM

Bohrtechnik GmbH was used in the anchoring work. A second layer of ground anchors were constructed to protect against

pressurized groundwater; however, some of the anchors will have to be removed because of conditions imposed by the city

of Düsseldorf. The project also included the scheduled removal of obstacles using a BAUER BG 40, dewatering for nine

months, as well as excavation and disposal of soil. The specialist foundation engineering and earth works project began in

December 2018, and was expected to be completed by the end of June this year.

7

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

C

&

G

Manufacturer of Red Devil Bits

PPaallmmeerr BBiitt,,

tthhee lleeaaddeerr iinn

nneeww bbiitt ddeessiiggnn

Palmer Bit Company

800-421-2487 • sales@palmerbit.com

www.palmerbit.com

The latest newly-designed bit

by Palmer Bit!

This double chevron, in a 3-wing or 4-wing

design, offers faster penetration than the

old style chevron and is more durable than

a step bit. It is performing extremely well

in medium formations and gravel.

8

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

9

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

Sponsorship available for special position

Hot Off the Press page.

DM450 Gets the

Job Done

The DRILLMAX

®

DM450 is a light-

weight, powerful rig for residential water

wells, commercial geothermal, and shal-

low cathodic protection drilling. With a

retractable table opening for 16-inch

casing and a 12,000-pound winch with

two-part line, it is perfect for drilling up

to 1000 feet deep. Mud pump options

up to 5½x8 duplex and up to 3x4x13

centrifugal, and air compressor options

up to 500/200 make this a strong, com-

pact unit.

The DM450 can be

equipped with a single

rod loader, or a CMAX

carousel loading system

for 320 feet of three-inch

drill pipe (16 pieces). It

features independent

systems for each main

circuit for continuous

drilling operations while

handling pipe.

For a link to this website, visit:

worldwidedrillingresource.com

Celebrate 71 Years of CGA

October 17 - 19

Grand Sierra Resort and Casino

Reno, Nevada

More information and online registration

can be found at: www.groundh2o.org

The California Groundwater Association is

Reclaiming Friendships and Bonds in 2019!

Schedule of Events (Subject to Change)

Thursday October 17

t

h

:

7:30 am - 5:00 pm Registration, Badge Pickup

8:00 am - 12:00 pm NV Regulations Seminar

8:30 am Golf

12:00 - 1:00 pm Lunch (On Your Own)

1:00 - 6:00 pm Exhibitor Move-In and Set-Up

1:15 - 2:15 pm Seminar A (Well Disinfection)

1:15 - 2:15 pm Seminar B (VFD Training - Low Harmonics/Yaskawa Drives)

2:30 - 4:30 pm Seminar C (OSHA Trench/Confined Spaces/Safety and Accident

Review-Silica Rules (OSHA))

2:30 - 4:30 pm Seminar D (Basics of E-Logging)

6:00 - 11:00 pm Bowling Meet and Greet

9:30 pm Texas Hold’em Tournament

Friday October 18

th

:

7:30 am - 4:00 pm Registration, Badge Pickup

8:00 - 10:30 am Additional Exhibitor Set-Up

9:00 - 10:00 am McEllhiney Lecture (Drilling Markets must Change - Gary Hix)

10:15 - 11:15 am Water System Council (Legal Updates Nationwide - Jessie

Richardson)

11:30 am - 12:00 pm General Membership Meeting

11:00 am - 12:00 pm Vendor Lunch

12:00 - 1:00 pm Attendee Lunch

12:00 - 4:30 pm Exhibit Hall Open (Sponsored Bar from 3:00 - 4:30)

4:30 - 5:15 pm Manufacturer & Supplier Meeting

4:30 - 8:00 pm Exhibit Teardown

4:30 - 5:30 pm Past Presidents Meeting

6:00 - 6:30 pm Reception, Silent Auction (Music by Andrew Quindt)

6:45 - 10:30 pm 71st Annual Banquet, Comedians, & Live Auction

Saturday October 19

th

:

8:00 - 10:00 am Registration, Badge Pickup

8:45 - 9:45 am Seminar A (Technology for the Small Contractor)

9:00 - 11:00 am Seminar B (Engines and Emissions)

11:15 am - 2:00 pm Lunch & CGAA Luncheon Program

12:30 - 2:30 pm Seminar C (DOT Preparedness)

12:30 - 2:30 pm Seminar D (Asset Protection/Succession/Disaster Readiness)

2:45 - 4:15 pm Wine Tasting

&DUROLQH6WUHHW

3XQ[VXWDZQH\3$

:HE6LWHKWWSZZZVWDULURQZRUNVFRP

(PDLOVDOHV#VWDULURQZRUNVFRP

)$;

Tobenoticed,

giveusacall:(850)547-0102

ore-mail:wwdr@ worldwidedrillingresource.com

12 AUGUST2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Oil/Water Exploration

by Harold White

I went out to do a water well site location for a new well not far out of town, less than a mile up the

mountain. The old gravel road to the place had been covered with Douglas fir trees that fell during the

snow, a wet snow that was like an ice storm but white.

You may know what a silver thaw is - rain that freezes when it hits anything and everything - streets,

power lines, sidewalks, towns, houses, everything covered with ice. It gets heavy, very heavy, causing

electric power to go off, which stops traffic and shuts down the town. The electric company fixes the

broken power poles and lines in town first, gets power to hospitals and medical facilities, then works their way out of town to

the country people who need medical help, food, and so on.

Some trees fell on houses and cut or chopped houses in half. My son Sean was lucky he’d just had some really big oak trees with

huge limbs removed from around the house before the snow happened, but a neighbor’s tree fell partially on his house. It landed on

the bedroom where he was sleeping. It made a huge noise in the night - scary, huh? That house probably would have been demolished.

When I got to the place I was going, the guy was outside. I stopped the car and met him. I mentioned about the trees that had

fallen across the road and how it must have taken a long time to cut and remove - at least 30-40 feet from the center of the road, with

a lot of pieces still left on both sides of the road. He said yes, it took along time. He had been stranded, unable to get to town for 13 days.

There was no electricity and of course trees were down everywhere. Truckloads of trees had already been hauled off before my arrival.

The man said his well was out behind the house a ways. A tree had fallen right on it, smashing the pump house which

caused the well to cave in. He said he was going to drill north of the well, about 15 feet from the existing well since there was

water everyplace on the property. The wire and plumbing were close, so he wanted us to drill there unless I said different.

My findings showed his spot to be a place I would not choose because the aquifer his pump was drawing from wasn’t

there, so I put the well site on the aquifer that feeds that well.

Harold Harold White may be contacted via e-mail to michele@worldwidedrillingresource.com

EXB

New Canadian Dealer for American Augers

American Augers has named the Brandt Group of Companies the exclu-

sive dealer for American Augers and Trencor products across Canada.

Adding the full line of American Augers and Trencor products to Brandt’s

existing underground equipment offering improves Canadian support and

distribution for a complete line that covers all sizes of equipment.

The two companies’ shared commitment to maximizing customer

uptime has resulted in a 24/7 support network. With American Augers’ and

Trencor’s premium-quality products and Brandt’s exceptional dealership

and parts warehouse infrastructure, Canadian contractors can expect bet-

ter-than-ever uptime even in the toughest conditions.

WHO’S IN THE NEWS

WHO’S IN THE NEWS

Breaking News

Breaking News

You can find additional announcements from Hole Products, the Society

for Mining, Metallurgy & Exploration (SME), and Women In Mining in our

online issue at: worldwidedrillingresource.com

Send your Who’s in the News to:

Bonnie@worldwidedrillingresource.com

Alberta Water Well Drilling Association

Manuel Zeballos is bringing his

extensive experience in the mining

and explosives industry to Rockmore

International as market development

manager - Latin America.

Lorrie Partridge, president of

Blackadar Insurance Agency, pre-

sented Diana with a personalized

Silver Anniversary Award to cel-

ebrate 25 years of service to the

company.

Mark presented Carlin with the

Highest Mark 2nd Year Water Well

Driller Apprentice Award.

The Honorary Membership Award

went to Jack Whitehead and was

accepted by Mark Holland.

Celebrating our 70

th

year in business!

Complete line of Water Well and Environmental Drilling Supplies

Featuring

Casing Grips

and Elevators

that we

manufacture

Bill Johnson Equipment Company

21 S. 40th St., Phoenix, AZ 85034

(602) 275-5415

5811 NE Columbia Blvd., Portland, OR 97218

(971) 229-1288

www.billjohnsonequipment.com

13

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

The Un-Comfort Zone II

by Robert Evans Wilson, Jr.

You have a Secret Super Power

Yes, you really do have a secret super power, although it might be better described as a hidden

super power since you’re probably not aware of it, which means you’re not using it. Will this super power

get you in the next Marvel Avengers movie? Probably not, but it might help you write it.

This super power is amazing because it will enable and empower you to do many things. However,

like most “real-world” abilities, you will have to work at developing it. I’ve got to warn you, there are peo-

ple out there who do not want you to discover this power. Why do people not want you to discover your power? Because if you

use it, you might rock the boat. And what happens when you rock a boat? Yes, people fall out. Then what happens? Now you

don’t have to worry about anyone drowning, we’re just speaking figuratively here, but they will be left behind; and people don’t

like to be left behind, it makes them angry and afraid. Some of them will be eaten by sharks - figuratively speaking that is.

If you develop this power extremely well, some psychologists will say you have a mental illness, but don’t listen to them.

Don’t listen to any of the naysayers because they are just envious. They will envy you because you will recognize opportunities

they will miss. You will handle change like a boss, while they cower in fear. You won’t have to worry about going senile as you

get older. No wonder they’re envious.

What is this secret super power? It’s creativity. It is a power you were taught to suppress when you were a child. Because

of this, many people believe creativity is a gift only some people are born with, but it is actually a skill which can be redeveloped

at any age. You see, instead of being allowed to freely use your imagination, you were trained to conform. You were taught

that curiosity is dangerous; questioning authority and challenging the status quo is antisocial; listening to different viewpoints

is heresy; and experiencing new things is a waste of time. But if you want to have an innovative mind, you must do all of these.

Innovation is not just for big corporations, it’s for everyone because when you embrace the innovator’s lifestyle and open

your mind to more creative thinking, wonderful things can happen. There is nothing more satisfying than being enmeshed in

the creative process. When you create something, you develop self-confidence. The more time you spend in creative activity,

the more you will believe in yourself. The more successful you are, the more persistent you become; the more willing you are

to take risks; and the more comfortable you become with change.

To develop this skill, this super power, you must learn to get a different perspective, to see things in different ways, so you

can think different thoughts and come up with new ideas. An idea is simply combining two or more existing concepts/ideas

into something new. Your challenge will be to look for connections or patterns where no one has seen one before. If you want

to invent a better mousetrap, then start with a goal and work backward from there, to how you might make it happen.

Creativity is a critical skill in today’s constantly changing world. Intel Chairman Andrew Grove described it succinctly and

accurately when he said, “Adapt or die.” Change is all about creative destruction, a term coined in the 1940s by economist

Joseph Schumpeter, to describe what happens when a new technology makes an old technology obsolete. Creative destruction

is like a steamroller without a driver heading right toward your business, and there is nothing you can do to stop it. You can

only prepare. It’s happening faster than ever before and will only speed up. If you aren’t changing with the changes going on

around you, you’ll get left behind, and probably eaten by sharks - figuratively speaking.

You can start developing your super power by exposing yourself to new things, new experiences, and different viewpoints.

When you have new experiences, you lay down new neural pathways in your brain. In other words, you have expanded your

thinking ability and your store of knowledge - which gives you more stuff with which to create. The more of these electrical

connections you create, the less likely you’ll suffer senility as you age. Plus, when you experience new things, you stimulate

the dopamine receptors in your brain which makes you feel good. When

you experience new things with your significant other, you'll rekindle the

romantic feelings you had when your love was new, and you know where

that leads.

So take a class on a subject that makes you curious. Read a magazine

or blog on a topic you know nothing about. Eat an ethnic food you’ve never

tasted. Imagine a new use for an old product, then do it again and again.

Write with your nondominant hand. Sleep on the wrong side of the bed. Talk

like a pirate. Most of all, have fun!

Robert

Robert is an author, humorist, and innovation consultant. He works

with companies that want to be more competitive and with people who

want to think like innovators.

For more information on Robert, visit www.RobWilsonSpeaker.com

or contact him via e-mail to michele@worldwidedrillingresource.com

D

e

a

l

m

a

k

e

r

s

Send your deals to:

michele@

worldwidedrillingresource.com

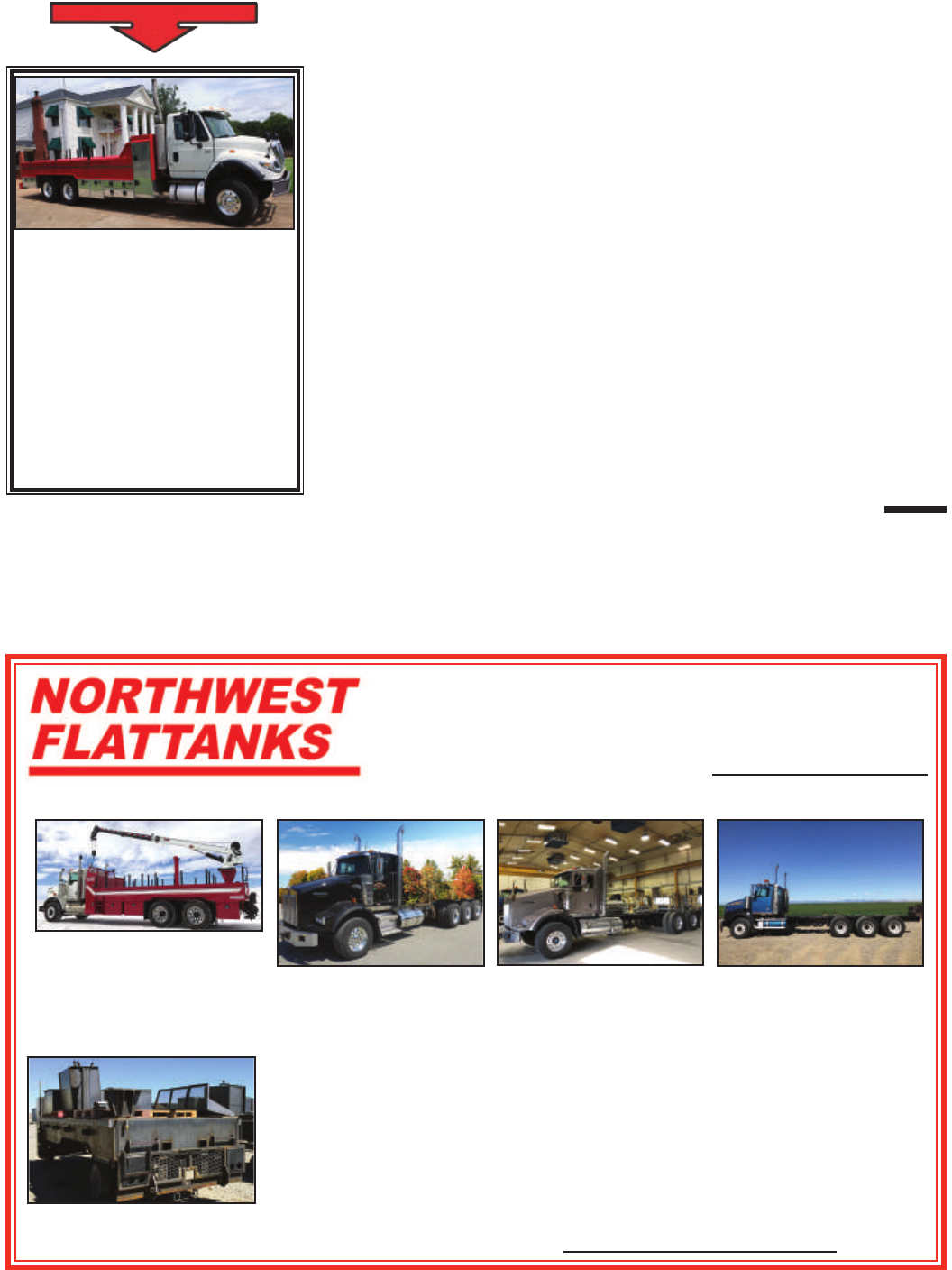

This 4x3 pump hoist from TDH Manufacturing of

Haslet, Texas, was delivered to Hunter Snelling of

Odenheimer Co. in Orefield, Pennsylvania.

TDH Manufacturing

14

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

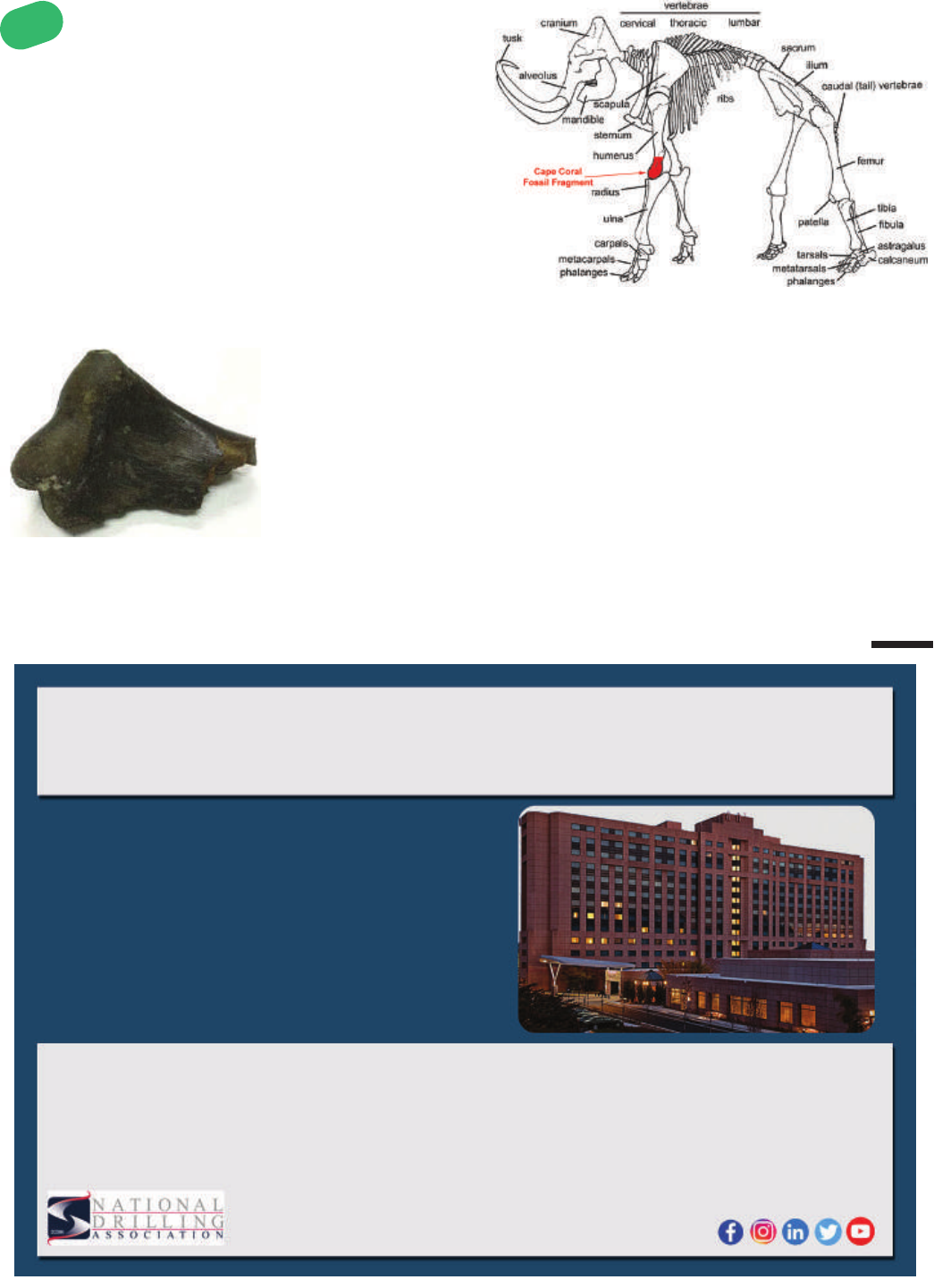

A Mammoth Find

Adapted from Information by

A

rchaeological and Historical Conservancy, Inc.

The City of Cape Coral, Florida, contracted with Greeley &

Hansen to design the potable water, sanitary sewer, dual water

irrigation, storm drain, and road reconstruction for the North 2

U

tilities Extension Project. During deep utility trenching, a con-

struction crew discovered what is believed to be a bone fragment

from a mastodon or mammoth. It is believed to be a part of the

animal’s humerus bone, which is a bone in the arm running from

the shoulder to the elbow. This specific fossil would have con-

nected the humerus to the elbow, and is about one foot in length

and ten inches in width.

The fragment is considered to be at least 12,000 years old. During this period, glacial retreat led to the formation of

savannas across Florida, allowing herds of mammoth, bison, antelope, and horse to roam the peninsula.

An archaeologist from Archaeological and Historical Conservancy, Inc. (AHC) met

with project engineers and recorded all information. Since the trench had been filled be-

fore his arrival, he documented the stratigraphic profile of a lift station in close proximity

to the find. His observations suggest the bone likely came from a horizon of gray clayey

sand below several more superficial horizons of fine, poorly drained sands and clays.

Although an isolated find, fossils of this type are seldom found in isolation. A larger

fossil bed is usually found in the immediate vicinity with the fossilized remains of other

animals. AHC has worked three miles southeast of the find and recovered large quantities

of broken fossil bones, suggesting a similar bone bed deposit there as well.

Fossil bones are not uncommon in the area. However, according to the Florida Museum

of Natural History, there are only two recorded sites in the county with finds pertaining to this time period. This is likely a result

of the sites being underreported, rather than not existing, since most fossil beds are found during deeper excavations, such

as quarrying, deep utility, and lake excavations.

Although the bone is an intriguing find, its semi-mineralized state indicates it likely predates human occupation of the

area, so it does not fall under the provisions of Florida statutes relating to cultural resources.

ENV

September 26-27, 2019

Hyatt Regency Dulles

Herndon, Virginia

For more information call 877-632-4748

or visit www.nda4u.com

Save the Date

2019 NDA Convention

Exhibitor & Sponsor Opportunities are Available!

Golf Outing - President’s Dinner with Awards & Entertainment -

Presentations for CE Credits - Outdoor Rig Displays - and More...

16

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

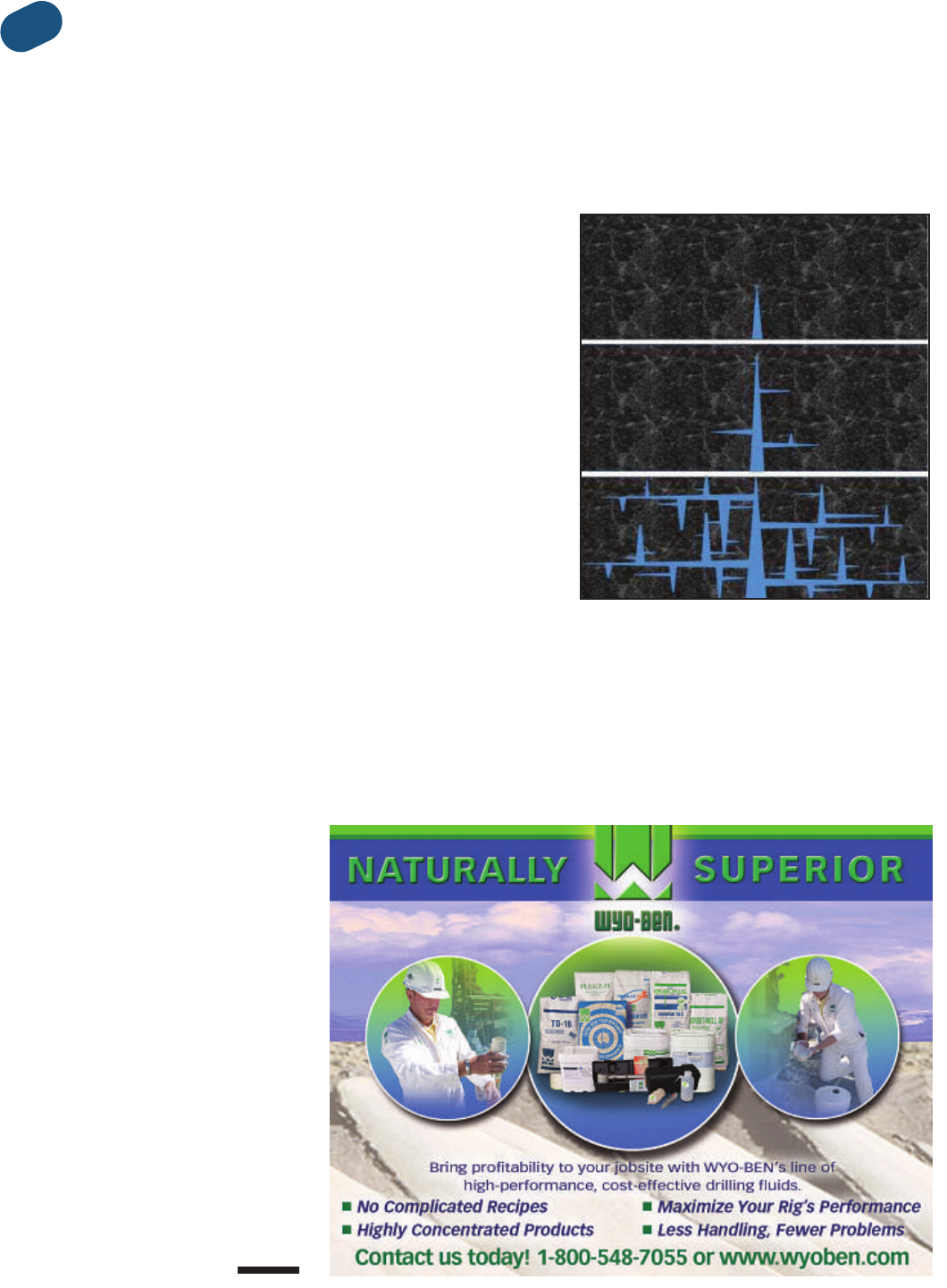

New Model May Lead to More Efficient Hydraulic Fracturing

Adapted from Information by Los Alamos National Laboratory

a

nd the U.S. Department of Energy

The United States has been hydraulic fracturing for decades, making the country a pioneer in refining the process of extracting

gas and oil through fractures. The next step would be to learn more about how fractures work and move, which is exactly what

researchers at Northwestern University and Los Alamos National Laboratory are working on. Its latest computational model is capable

of predicting previously hidden fractures and more accurately interprets the amount of gas being released during the process.

“Our model is far more realistic than current models and software used in the industry,” said Zdeněk Bažant, McCormick

Institute professor and Walter P. Murphy professor of civil and environmental

engineering, mechanical engineering, and materials science and engineering

at Northwestern’s McCormick School of Engineering. “This model could help

the industry increase efficiency, decrease cost, and become more profitable.”

Although the industry has seen a great deal of growth, a great deal of

the fracturing process remains a mystery. With the fractures occurring deep

underground, it’s impossible for researchers to see how fractures move and

release the gas from shale.

“This work offers improved predictive capability that enables better con-

trol of production while reducing the environmental footprint by using less

fracturing fluid,” said Hari Viswanathan, computational geoscientist at Los

Alamos National Laboratory. “It should make it possible to optimize various

parameters such as pumping rates and cycles, changes of fracturing fluid

properties such as viscosity, etc. This could lead to a greater percentage of

gas extraction from the deep shale strata, which currently stands at about

5% and rarely exceeds 15%.”

The new model used information gathered by studying the closure of

existing fractures caused by ancient tectonic events, and considering water

seepage forces not previously taken into account. Researchers were able

to develop a new mathematical and computational model showing how

branches form off vertical cracks during the fracturing process, allowing more

natural gas to be released. The model is the first to predict this branching

while being consistent with the known amount of gas released from the shale

during this process.

Classic fracture mechanics research predicted cracks which run verti-

cally from the horizontal bore, with no branches. However, these cracks

alone cannot account for the quantity of gas released during the fracturing process. In fact, the gas production rate is about

10,000 times higher than calculated from the permeability measured on extracted shale cores in the laboratory.

Other researchers previously hypothesized the hydraulic cracks connected with preexisting cracks in the shale, making it

more permeable. However, Bažant and his fellow researchers found the tectonically-produced cracks, which are about 100

million years old, must have been closed

by the viscous flow of shale under

stress. This led the team to hypothesize

the shale layer had weak layers of

microcracks along the closed cracks,

and it must have been these layers

which caused the branches to form off

the main crack. Unlike previous studies,

they also took into account the seepage

forces during diffusion of water into

porous shale. When they ran a simula-

tion of the process using this new idea of

weak layers, along with the calculation

of all the seepage forces, they discov-

ered their results matched those found

in reality.

“We show, for the first time, that cracks

can branch out laterally, which would not

be possible if the shale were not porous,”

Bažant said. After establishing these basic

principles, researchers hope to model this

process on a larger scale.

Branching into densely spaced hydraulic cracks is an

essential process for gas and oil extraction from shale.

Although it is suspected to occur, existing mathematical

models and current software aren’t able to predict it. A

new model from Northwestern University and Los Alamos

National Laboratory presents a method to not only predict

when the branching occurs, but also how to control it.

G&O

17

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

DD

DD

oo

oo

ee

ee

ss

ss

yy

yy

oo

oo

uu

uu

rr

rr

rr

rr

ii

ii

gg

gg

nn

nn

ee

ee

ee

ee

dd

dd

hh

hh

ee

ee

ll

ll

pp

pp

??

??

W

W

e can t

e can t

ake care of your new or not so new rig.

ake care of your new or not so new rig.

Remount

Remount

s • Rebuilds • Overhauls

s • Rebuilds • Overhauls

OO

OO

uu

uu

rr

rr

dd

dd

ii

ii

ss

ss

tt

tt

rr

rr

ii

ii

bb

bb

uu

uu

tt

tt

oo

oo

rr

rr

ss

ss

aa

aa

rr

rr

ee

ee

::

::

DD

DD

rr

rr

ii

ii

ll

ll

ll

ll

ii

ii

nn

nn

gg

gg

SS

SS

uu

uu

pp

pp

pp

pp

ll

ll

yy

yy

&&

&&

MM

MM

ff

ff

gg

gg

..

..

77

77

33

33

00

00

11

11

HH

HH

ww

ww

yy

yy

11

11

88

88

33

33

SS

SS

oo

oo

uu

uu

tt

tt

hh

hh

AA

AA

uu

uu

ss

ss

tt

tt

ii

ii

nn

nn

TT

TT

XX

XX

77

77

88

88

77

77

44

44

44

44

TT

TT

ee

ee

ll

ll

::

::

((

((

55

55

11

11

22

22

))

))

22

22

44

44

33

33

-

-

11

11

99

99

88

88

66

66

FF

FF

aa

aa

xx

xx

::

::

((

((

55

55

11

11

22

22

))

))

22

22

44

44

33

33

-

-

11

11

00

00

99

99

11

11

CC

CC

hh

hh

ee

ee

cc

cc

kk

kk

oo

oo

uu

uu

tt

tt

oo

oo

uu

uu

rr

rr

WW

WW

ee

ee

bb

bb

ss

ss

ii

ii

tt

tt

ee

ee

ff

ff

oo

oo

rr

rr

aa

aa

ll

ll

ii

ii

ss

ss

tt

tt

oo

oo

ff

ff

uu

uu

nn

nn

ii

ii

tt

tt

ss

ss

ff

ff

oo

oo

rr

rr

ss

ss

aa

aa

ll

ll

ee

ee

..

..

ww

ww

ww

ww

ww

ww

..

..

dd

dd

ss

ss

mm

mm

-

-

mm

mm

aa

aa

yy

yy

hh

hh

ee

ee

ww

ww

..

..

cc

cc

oo

oo

mm

mm

18

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Notes from the Groundwater Guy

by Thomas E. Ballard, P.G., C.H.G.

Southeast Hydrogeology, PLLC

What Makes an Efficient Well? Part 2

In Part 1, we discussed what well efficiency is and how it is measured - but what can we do to ensure

we end up with the most efficient well possible? In general, an efficient well starts with design of the well,

but also includes construction factors.

Well design considerations include:

1. A proper well screen with sufficient open area to allow for reasonable entrance velocities and reduce the turbulent flow

of groundwater into the well;

2. Proper distribution of well screen can enhance the flow of water to the well and reduce turbulent flow and groundwater

velocity. Due to the design of the screen open areas, wire-wrap screens will be more efficient than mill slot screens;

3. Sufficient length of screen and penetration of the aquifer will allow for mainly horizontal flow to the well. Any vertical

flow component will result in head losses and reduced well efficiency; and

4. Properly sized gravel pack with gravel as spherical as possible to maximize flow into the well screen.

Well design considerations are really focused on maximizing horizontal flow of water to the well and minimizing the vertical

component which can reduce head losses and enhance efficiency. Reduction of turbulent flow to the well also enhances effi-

ciency by reducing load on the pump, as well as reducing other problems such as possible cavitation.

Well construction considerations include:

1. Proper well development is a key well construction factor as it has the net effect of increasing the permeability of the

formation surrounding the well; and

2. Proper placement of the well screen with respect to the most significant water-bearing zones in the aquifer.

As discussed previously, proper well development is one of the most significant factors in not only producing an efficient

well, but also in maximizing the capacity of the well. Time and money spent on proper well development gives a significant

“bang for the buck” investment in an efficient, quality well, yet it is often one of the most overlooked parts of the well construction

process.

Proper placement of well screen is a function of conducting an electronic log (elog) of the borehole and performing ade-

quate zone testing prior to committing to final well design plans. This allows for proper placement of screen, as well as sizing

of screen and gravel pack.

While there are a number of considerations which must be taken into account

to design and construct an efficient well, the increased capacity and reduced costs

of operating an efficient well make the process well worthwhile.

Tom

Tom Ballard may be contacted via e-mail to

michele@worldwidedrillingresource.com

The 2019 National Drilling Association Convention

will be September 26-27, at the Hyatt Regency

Dulles in Herndon, Virginia. The event starts with

the Annual Joe Scribellito Jr. Memorial Golf Outing

at Herndon Centennial Golf Course on Thursday.

There is a day excursion planned for those not golfing.

Cocktails and visiting with exhibitors is from 5:00-

6:00 p.m., followed by the president’s dinner, award

presentations, entertainment, and Chinese raffle.

Friday has several presentations for continuing education credits, along with

more time to view vendor displays. A meeting of all chapters is set for 4:30 p.m.

Go to www.nda4u.com

for more information and to register.

Where are you planning to go?

How about including this show:

See more events at www.worldwidedrillingresource.com online issue.

New & Used Bits,

HDD Bits & Tools,

Drag Bits & Wings,

Bolt-On Drag Bits,

Reverse Circulation

Tools, Hole Openers,

Claw Bits, Stabilizers, Subs,

Custom Tooling & Welding,

Hammer Bits, Drill Collars,

Pipe Wipers, and Drill Pipe.

Office: (661) 834-4348

Rod Henderson / Eran Henderson

661-201-6259 • 661-330-0790

sales@bitcobits.com

www.bitcoinc.us

19

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

W

T

R

Join

WWDR

WWDR

20

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Game-Changing Technology for Geothermal Drilling?

A

dapted from Information by Texas A&M University and the Geothermal Energy Association

People have been using geothermal energy for thousands of years. The indigenous people of New Zealand, the Maoris,

as well as Native Americans, used geothermal energy for cooking food, washing, bathing, warmth, preserving, ceremonial rit-

uals, and healing. Ancient Greeks and Romans enjoyed geothermal-heated spas. Prior to Mount Vesuvius erupting and de-

stroying Pompeii, people tapped the hot water from the volcano and used it to heat their buildings.

We continue to tap into the heat radiating from our planet today. Modern technology allows us to drill deep into the ground

and transform the heat underground into electricity. One of the challenges with drilling geothermal wells is the presence of

hard rocks, such as granite, which slows down the drilling process and wears down drill bits. This ultimately leads to increased

drilling time and expenses. Scientists with Texas A&M University are working on a way to resolve this issue.

A team of researchers from the J. Mike Walker '66 Department of Mechanical Engineering at Texas A&M University is cur-

rently developing new drilling technology to make drilling geothermal wells more efficient. It’s called Shockwave and Plasma

Accelerated Rock Cracking (SPARC).

Leading the SPARC project is Dr. David Staack, associate professor, Sallie and Don Davis ’61

Career Development Professor, and College of Engineering director of laboratory instruction re-

spectively. His team includes Dr. Dion Antao, assistant professor; Dr. Alan Palazzolo; James J. Cain,

Professor I; and Dr. Bruce Tai, assistant professor.

“The drilling technology that we are working on has the potential to increase drilling rates (rate

of penetration) and reduce the wear and tear of traditional drill bits. This is achieved by locally pre-

stressing or precracking the rock being drilled prior to the cutting action of the drill bit,” said Antao.

The team’s SPARC technology places high-voltage electrodes to the tip of traditional drill bits.

These electrodes emit a microscopic plasma discharge to shock the rock and crack it. By creating

these small fractures and weakening the rock, the drill head, using conventional diamond cutters,

is able to break through the material easier, increasing the rate of penetration (ROP).

Along with setting the stage for further development of geothermal energy, using electric plasma

bursts to increase the ROP will also streamline the drilling process, making it more cost effective.

“It’s very exciting to be able to apply my expertise in machining research to study rock drilling

with a real-world application,” said Tai. “This is truly a novel, interdisciplinary idea that will be a game changer.”

A game changer U.S. Secretary of Energy Rick Perry summed up in his related press release by saying, “Geothermal energy

is a clean and efficient baseload energy resource, making it an important part of our nation’s diverse energy portfolio. Developing

new, efficient drilling technologies will reduce these costs and increase the availability of this domestic renewable energy resource.”

Dr. David Staack.

G

E

O

Simulator Use Improves Results in North America

Adapted from Information by Immersive Technologies

As one of the world’s largest suppliers of advanced equipment simulators, Immersive Technologies has seen consistent

growth in North America since deploying its first-generation units in the early 2000s.

Those who used the early models of simulators are upgrading

to the latest models, while new customers are discovering the value

of simulator training at an accelerated rate. North American cus-

tomers are achieving great results in targeted areas such as lower

spot times, higher dig rates, and reduced machine abuse.

Longtime customer Rio Tinto Kennecott, in Utah, is now using

Managed Services and a transportable PRO4 to train operators on

wet weather conditions. The majority of the company’s haul truck op-

erators have less than two years experience. With the mild winter of

2017/2018, many of them have not dealt with the challenges of op-

erating in heavy snow. Kennecott is running all operators through

simulator-based training to build confidence in driving in those con-

ditions. While the operators are being trained, data will be generated

to help identify other opportunities for targeted training to improve

safety, productivity, and unscheduled maintenance. New-hire training

is also part of Kennecott’s program and will continue to be a focus

into 2019.

In Wyoming, at Peabody’s North Antelope Rochelle Mine (NARM), a recently concluded Managed Services project pro-

duced some impressive results. Over the five-month course, NARM achieved a 2.4-second spot time reduction and a 57%

improvement in Operator Induced Machine Events (Alarms). “NARM continues to be one of the top achievers in operator

improvement. Their commitment to the safety and improvement of their staff is apparent by the results they achieve,” said

Anthony Bruce, Immersive Technologies regional vice president - North America.

In Mexico, an underground hard rock customer described how the Embedded Trainer helped them achieve a:

;

96% reduction on rear brake heating events

;

86% reduction on front brake pressure drop events

;

79% reduction on transmission abuse events

;

4.5% reduction on fuel consumption, representing $444,181 in annual savings

“The fusion of Managed Services and simulator technology is a powerful combination as North American customers have

quickly realized following their implementations over the last decade. The fully supported solution by Immersive Technologies’

Managed Services architecture drives

quantifiable return on investment. It in-

cludes proactive supervision to drive best

actions and access to select intellectual

property for training and continuous

Improvement,” Bruce stated.

Immersive Technologies works with

original equipment manufacturers includ-

ing Caterpillar, Komatsu, and Liebherr

to create realistic, accurate simultators

that replicate how the equipment oper-

ates. Hundreds of mining companies, in

44 countries around the world, use

these simulators to enhance the safety

and productivity of their operations.

21

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

MIN

October Issue Deadlines!

Space Reservation:

August 25

th

Display & Classified

Ad Copy:

September 1

st

Open the Doorway to all

the Event Photos during

Alberta Water Well Drilling

Association 2019.

To see all the photos from this event, go

to www.worldwidedrillingresource.com

Feel free to download at will and print the photo(s) of your choice.

Compliments of

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

.

Photos are copyrighted and released for personal use only

- no commercial use permitted.

Congratulations to Sheena (L)

for being elected as the new

Executive Secretary for AWWDA!

What Happened in

Pittsburg County, Oklahoma?

Adapted from Information by the

U

.S. Chemical Safety Board

It was January 22, 2018, when an oil rig in Oklahoma

suffered a deadly blowout, killing five workers. The U.S.

Chemical Safety Board (CSB) has been investigating

t

he incident to try to identify what caused the accident and,

more importantly, what can be done to prevent something

like this from happening again. In addition to spotting gaps

in the regulations governing onshore drilling safety, the

report discovered inadequacies in safety management

systems and industry standards. CSB Interim Executive

Dr. Kristen Kulinowski said, “Our investigation found

significant lapses in good safety practices at this site.

For over 14 hours, there was a dangerous condition build-

ing at this well. The lack of effective safety manage-

ment at this well resulted in a needless catastrophe.”

According to the report, the ultimate cause of the

blowout and rig fire was the failure of two preventive

barriers. The primary barrier was the hydrostatic pressure in the well, produced by drilling mud;

the secondary barrier was human detection of gas flowing into or expanding in the well and acti-

vation of the rig’s blowout preventer. The report explains how unplanned underbalanced drilling

and tripping operations allowed a large quantity of gas to enter the well, while critical flow checks,

used to determine if gas is in the well, were not performed.

The investigation identified several factors leading to the failure of both barriers including a lack

of planning, training, equipment, skills, and procedures. Surprisingly, there are no regulations specifically

for onshore gas and oil drilling. Gas and oil well drilling is exempt from Occupational Safety and Health

Administration’s (OSHA’s) Process Safety Management standard which covers

safety for chemical processing facilities. OSHA has been utilizing the general duty

clause, which “protects workers from serious and recognized workplace hazards,”

but fails to address the unique safety hazards associated with gas and oil drilling.

The report also revealed how inadequate and ineffective the alarm system

was. It would have sounded constantly with noncritical alarms 14 hours prior to the

blowout. Having so many noncritical alarms is most likely the reason both the day

and night drill operators chose to turn off the entire system. Without the critical

alarms, the workers were unaware of the flammable gas entering the well.

Investigator Lauren Grim said, “An effective alarm system is a method to help

workers become aware of hazardous conditions, like gas entering the well. With

the alarm system off, the safety of the operation solely relied on workers to either

visually identify signs of the gas influx or calculate volume differences that could

indicate gas influx, and in this case, neither method was effective, and workers

were unaware of the very large gas influx into the well before the incident. As a

result, the workers had little knowledge of the impending disaster.”

At the time of the blowout, three workers were in the driller’s cabin. Two other work-

ers who were on the rig floor ran into the driller’s cabin during the blowout and fire. There

was no way for the men to escape and they suffered thermal burn injuries, as well as

smoke / soot inhalation. “When the blowout mud and gas ignited, it created a massive

fire on the rig floor. All five of the workers inside the driller’s cabin were effectively trapped

because fire blocked the driller’s cabin’s two exit doors. Our investigation found that

there is no guidance to ensure that an emergency evacuation option is present onboard

these rigs or can protect workers in the driller’s cabin from fire hazards,” stated Grim.

The CSB is calling on the American Petroleum Institute (API) to address design

improvements to protect driller’s cabin occupants from blowout and fire hazards. The

report recommended API create guidance on Alarm Management for the drilling industry,

to help ensure alarm systems are effective in alerting drilling crews to unsafe conditions.

As onshore gas and oil production increases across the country, it is important

the industry uses proven and reliable safety standards and practices. If some of

these safety practices had been in place, this tragedy could have been averted.

The most viable exit door for those

in the driller’s cabin was hinged so

when the door was opened, it blocked

the escape path.

Atlantis Vault

Atlantis Vault

• Self-Contained

• Self-Contained

• Simple installation

• Simple installation

• Trouble-free operation

• Trouble-free operation

For more information call:

(270) 786-3010

or visit us online:

www.geothermalsupply.com

23

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

LOOK

Surprise, surprise, surprise

H

eisey Machine is on Facebook!

www.facebook.com/floatingsubs/

Check it out - follow and like it.

Ask about their new 2470SX lathe.

They hope you had a great time

at JUBILEE!

G&

O

www.starironworks.com

257 Caroline Street

Punxsutawney, PA 15767

800-927-0560 • 814-427-2555

Fax: 814-427-5164

SERVING THE WATER WELL INDUSTRY

Serving the Drilling Industry

24

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Industry Announcements

Eijkelkamp North America has been selected as a new dealer

for Fraste rigs in the Eastern United States. Based in North Carolina, the

Eijkelkamp Team is excited to offer the Fraste conventional rig series, as

well as after-sales service, spares, and even rental rigs.

Mimir Invest AB has acquired Epiroc AB’s geotechnical consumables product line.

With manufacturing sites in Scotland, Finland, and the United States, the geotechnical drilling

c

onsumables product line is a global market leader providing primarily down-the-hole hammers

and related drill bits, as well as casing advancement systems for the infrastructure, construction,

gas and oil, and scientific industries.

“We have found a better home for this business, which we have defined as a non-strategic core area for us,” said Helena

Hedblom, senior executive vice president mining and infrastructure for Epiroc AB. “We believe it will have a good future with

the new owner, Mimir.”

Managing Partner for Mimir, Eric Bork said, ”We are happy partnering with the employees and customers of the business,

combining Mimir’s industrial and investing expertise with the high-quality staff, expertise, and know-how of the geotechnical

consumables business. This combination provides a great foundation for forming a new, growing business.”

Komatsu Ltd. has agreed to purchase global mining technology and workforce optimization firm Immersive Corporation

Pty. Ltd. through its wholly-owned subsidiary in Australia,

Retaining its headquarters in Perth, Western Australia, Immersive Technologies will op-

erate as an independently managed, wholly-owned subsidiary of Komatsu. The company

will continue to operate under its existing name and branding, while continuing to collab-

orate with all equipment manufacturers to address performance improvement challenges of mixed equipment fleets.

“We have been particularly impressed by Komatsu’s bold vision for the future of mining and their proactive steps to pursue it.

We are very pleased that Komatsu sees Immersive Technologies as having an important role in this future. Further, we see

Komatsu’s high level of customer focus, which supports collaboration between competing mining suppliers, to benefit mining

customers, as being highly aligned to Immersive Technologies’ business,” said Wayde Salfinger, executive director and cofounder.

A Consultant’s Perspective

b

y Edward E. Everett, CPG

Strata Environmental Services, Inc.

Water Level Data Recorders - A Blessing or a Curse?

My hydrogeologic education and early experience in the field involved manually collecting aquifer

test data, then taking the data, plotting it by hand on logarithmic graph paper, then doing manual curve

matching to determine aquifer characteristics. Some equations just required entering various data into

the formula and calculating the results (with the use of those new-fangled calculators). If a calculation resulted in a transmis-

sivity value of 43,576.2 gallons per day per foot (GPD/ft), we rounded up the number to 44,000 GPD/ft, or if we wanted to be

precise, we rounded the number to 43,600 GPD/ft.

I understand the concept of GPD/ft, but now we use feet squared per day, which I cannot wrap my brain around.

Importantly, we understood we were characterizing an aquifer of many acres, or even square miles from data collected from

a couple of wells representing a miniscule percentage of the aquifer area. Consequently, it was our opinion that rounding of

our calculated numbers was probably as accurate as we needed to be, given the amount of information we had on the aquifer.

Now we collect aquifer test data with data loggers which can be programmed to collect water levels at just about any

designated time interval. In a recent test, I set the loggers to record on a logarithmic scale, with a maximum time interval of

15 minutes. During the initial start of the test, the data loggers recorded 63 readings in the first minute, with the number of

readings decreasing until the 15-minute increment was reached after 2.5 hours. Where I work, our regulatory agencies want

the early time data because it is “so important”. So what do roughly 100 readings in the first three minutes of the test tell us?

(We used to have to hustle to get three readings in this same time period.)

Pump discharge is based on total dynamic head, so when water levels in a well are high (at the start of a test), the pump

will produce a higher volume of water. Most of the time, the drop pipe and discharge pipe are empty when the test starts, fur-

ther reducing total dynamic head. This is especially true when testing a well hooked to an irrigation system, which may have

hundreds of feet of piping before the water reaches the irrigation heads. Eventually, the system reaches an equilibrium pres-

sure, the water level in the well reaches relatively stability, and the pumping rate remains constant. At that time, we meet the

requirements of a constant-rate aquifer test.

So what does all the early time data tell us? In my opinion, it tells us more

about the system configuration and pump design than it actually tells us about the

aquifer response to pumping. This information occurs after system pressure stabi-

www.starironworks.com

257 Caroline Street

Punxsutawney, PA 15767

800-927-0560 • 814-427-2555

Fax: 814-427-5164

SERVING THE CONSTRUCTION INDUSTRY

Serving the Drilling Industry

25

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

W

T

R

Everett cont’d on page 44.

by Tim Rasmussen

The bridge looked old. There were some broken deck boards here and there. Seth

Weilage decided to take a closer look, so he pulled off to the side and climbed down out of the drill rig. He made his way down

t

he bank where he could get a better look at the condition of the bridge from the underside. He did not like what he saw. The

bridge had been built on large logs. It sagged a bit in the middle. There were no supporting timbers under it, except for one

which jutted at an angle out of the river to support one of the old logs.

As he stood there, a small truck came by and passed slowly over the structure. The bridge sagged a little under its weight.

Seth wondered what would happen if the full weight of the 10,000 or so pounds of rig was on it. He looked down at the water

below. It did not seem deep, and the stream was only about 30 feet wide. If the bridge broke and the rig went into the river, it

would never come out, or at least not come out in one piece and that not without a huge effort. In any event, the rig would

be ruined.

Seth came back up the bank just as Jon Hansen pulled up. He had been following Seth, driving one of our small 4x4

double cab trucks in which they had planned to come back. The village they were heading for was another 45 minutes farther

down the rough road that wound through the hills and valleys of Guatemala. They were on a mission to bring clean water to a

remote village which had none. Jon had been to the village before and had immediately been struck by the poverty of the

people there. He had been to poor villages, but this was one of the worst he had seen. It was

just a few shacks near the road and paths leading from the road into the heavy jungle vege-

tation. There were no public buildings or anything that looked like a school. There was only a

polluted stream for a water source. The people there were desperate for water.

Jon and Seth talked it over and decided they should not trust the bridge. It was not worth

risking the rig. Just upstream there was a place that looked like it had been a ford across the

river years ago, probably before the bridge was built. It looked like he could get down to the

creek okay, and there was a road up out of the river on the other side. Seth and Jon decided

they could probably cross there, hoping there were no huge rocks or holes in the streambed.

Easing down off the road, the rig swayed back and forth dangerously as Seth approached

the water. He could see the water was only a foot or so deep and the bottom was covered in

small rocks. There was no mud. As he got to the water, he decided not to stop and just kept

going with as much speed as he dared and as seemed safe.

Plowing through the creek, he came to the other side and started out of the water. For a

moment, the drive wheels seemed to slip and then caught, and he was up and out of the

creek. Then he was back on the road. “Thank you Lord,” he said out loud, but he did not stop

to marvel at what he had done. He just shifted into second and started back down the road toward the village. Toward the

people who needed the water. Toward the children the clean water would save. Yes, thank you Lord, for men like Seth and

Jon, who give of their time and talents to serve others.

If you have a heart for other people,

and the skills to run a drill, please come

and help.

Contact Gary Bartholomew at

509-466-5075 or 509-939-1941

Tim

Tim Rasmussen may be contacted

via e-mail to michele@

worldwidedrillingresource.com

27

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

AUGUST 2019

E

N

V

October Issue Deadlines!

Space Reservation:

August 25

th

Display & Classified

Ad Copy:

September 1

st

In Memoriam

George John Geisser III (1949~2019)

George John Geisser III of Attleboro, Massachusetts, and Savannah, Georgia, passed away May 26, 2019.

Born in Providence, Rhode Island, in 1949, George received his bachelor of science degree in civil engineering

from the University of Rhode Island in 1973. He was the proud owner, operator, and president of Geisser

Engineering Corporation, Allstate Drilling, and New England Foundation in East Providence.

Living a full life, George loved to travel, golf, boat, and spend time at his second home in Savannah. He especially treasured

time spent with his grandchildren.

He was a member of the Rhode Island Society of Professional Engineers, National Society of Professional Engineers,

American Society of Civil Engineers, East Providence/Seekonk Rotary, Elks Club, Society of St. Vincent de Paul, Wannamoisett

Country Club, East Greenwich Yacht Club, and Ledgewood Condominium Association - serving as president for many of them

during his lifetime. George had been named Young Engineer of the Year in 1984 and Rotarian of the Year in 1996-1997.

George leaves behind his wife of 46 years, Linda; children Kelly (Sean) and Gregory (Sarah); grandchildren Alexander,

Mackenzie, Lily, Molly, and Samuel; his father George Jr.; siblings, and other family.

David Eugene Barlow (1953~2019)

David Eugene Barlow of Gillette, Wyoming, passed away June 9, 2019. Born in Des Moines, Idaho, in

1953, David enlisted in the U.S. Navy during the Vietnam Era, where he served as a radio operator. Moving on

to civilian life, he was a disc jockey in Pawhuska, Oklahoma, before moving to Dallas, Texas, where he began

his career in the manufacturing/mining industry. He was employed at Ingersoll-Rand for 30 years, then with

Cate Equipment/Atlas Copco/Epiroc for 17 years, retiring as parts manager at Epiroc in Gillette earlier this year.

Preferring small town life, David was an outdoorsman who enjoyed camping, hunting, fishing, pets, and

critters. He was always ready to host by fixing an awesome brisket or some reward from a hunt. Family was

very important to him throughout his life. He loved to visit, be visited, or get updated on the phone.

David is survived by his wife Lori; children Michelle (Marc), David, Shawn, and Daniel (Kelsie); and granddaughter Ava.

The management and staff of

WWDR

WWDR extend their sympathies to George’s and David’s family and friends.

Lest we forget...

28

AUGUST 2019

WorldWide Drilling Resource

WorldWide Drilling Resource

®

®

Get Over It

by Tim Connor

I love T-shirts

and sweatshirts with

clever and some-

times provocative

sayings on them.

The souvenir shop

is always my first stop when travelling,

and trust me, I've found some really neat

ones. Recently, I took a day trip to one of

my favorite small North Carolina towns

and found one that simply said: "Get

Over It", so naturally I bought it.

So . . . what do you need to get over?

1

You didn’t have an ideal childhood.

1

You are not as attractive or hand-

some as you think you should be.

1

You were not educated at the

best schools.

1

Your parents didn’t love or support

you as much as they did another off-

spring.

1

You were treated unfairly in your

last career position.

1

Som eon e you car e abou t is

ignoring you.

1

Your best client isn’t returning

your phone calls or e-mails.

1

Your boss treats you like a bottom feeder.

1

How about - It's your turn _______________________!!!

Live wisely this year,

Tim